Macromolecule electrified cleaning method for substation power equipment

A technology of electric equipment and electrified cleaning, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, and cleaning methods using gas flow, etc., which can solve the problems of reducing the insulation of equipment and difficult cleaning of stubborn pollutants, and achieve protection Safety, elimination of stubborn pollutants, and effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

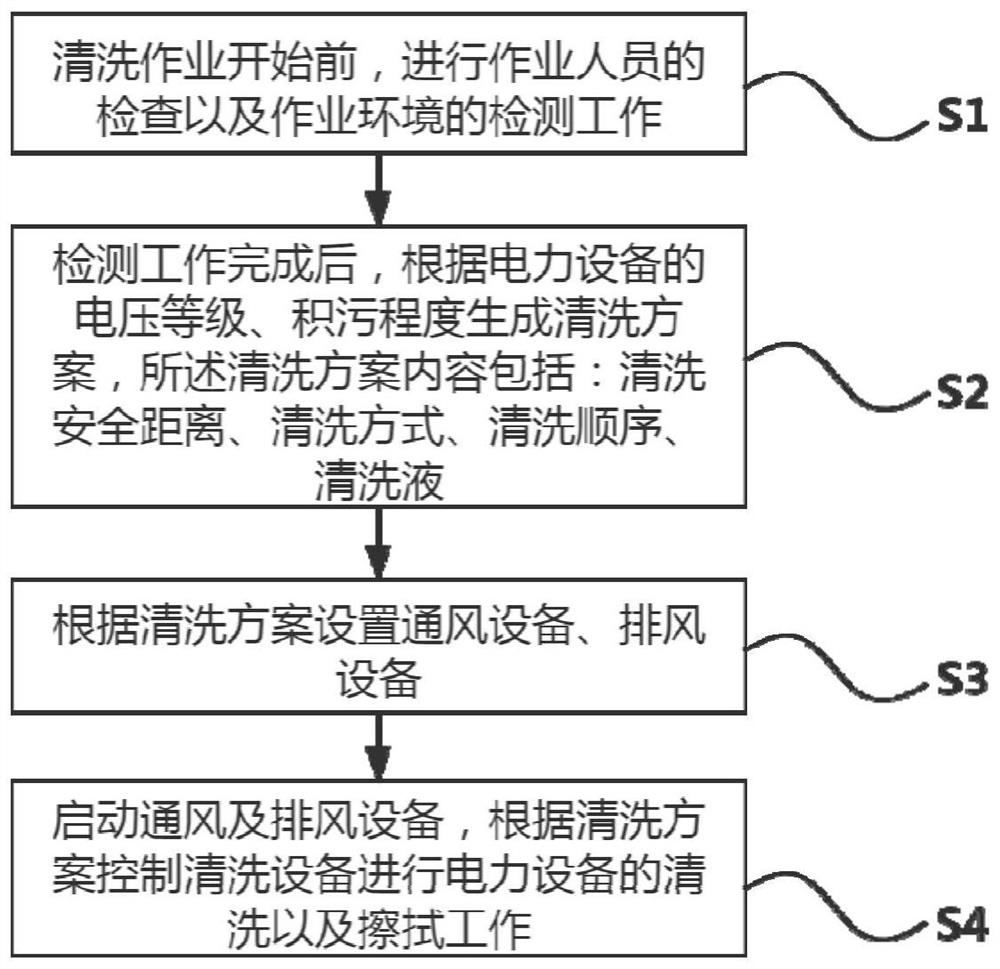

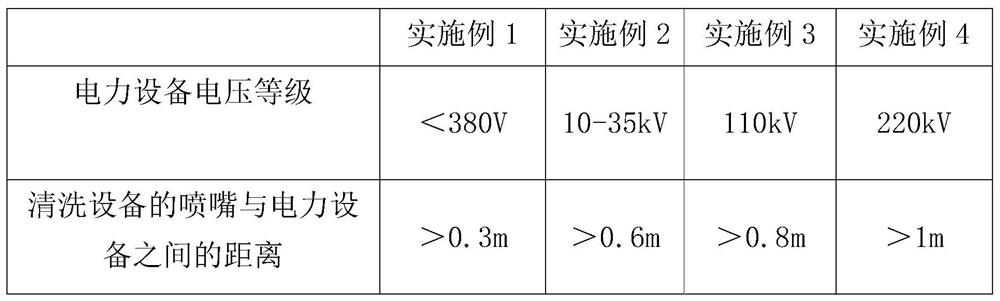

[0025] Such as figure 1 As shown, a polymer charged cleaning method for substation power equipment includes the following steps: S1: before the cleaning operation starts, check the operating personnel and detect the working environment; S2: after the detection work is completed, according to the voltage of the power equipment A cleaning plan is generated based on the grade and degree of contamination. The cleaning plan includes: cleaning safety distance, cleaning method, cleaning sequence, and cleaning liquid; S3: set ventilation equipment and exhaust equipment according to the cleaning scheme; S4: start ventilation and exhaust equipment According to the cleaning plan, the cleaning equipment is controlled to clean and wipe the power equipment.

[0026] In the above scheme, the inspection of the operators can ensure the continuity of the operation process and ensure the safety of the operators; the inspection of the operating environment can further improve the safety of the cl...

Embodiment 2

[0046] On the basis of Embodiment 1, the only difference of this embodiment is that the voltage level of the electrical equipment required for cleaning is 10kV to 35kV, and the distance between the nozzle of the cleaning equipment and the electrical equipment is set to be greater than 0.6 meters. Other parts are consistent with Example 1.

Embodiment 3

[0048] On the basis of Embodiment 1, the only difference of this embodiment is that the voltage level of the electrical equipment required for cleaning is 110 kV, and the distance between the nozzle of the cleaning equipment and the electrical equipment is set to be greater than 0.8 meters. Other parts are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com