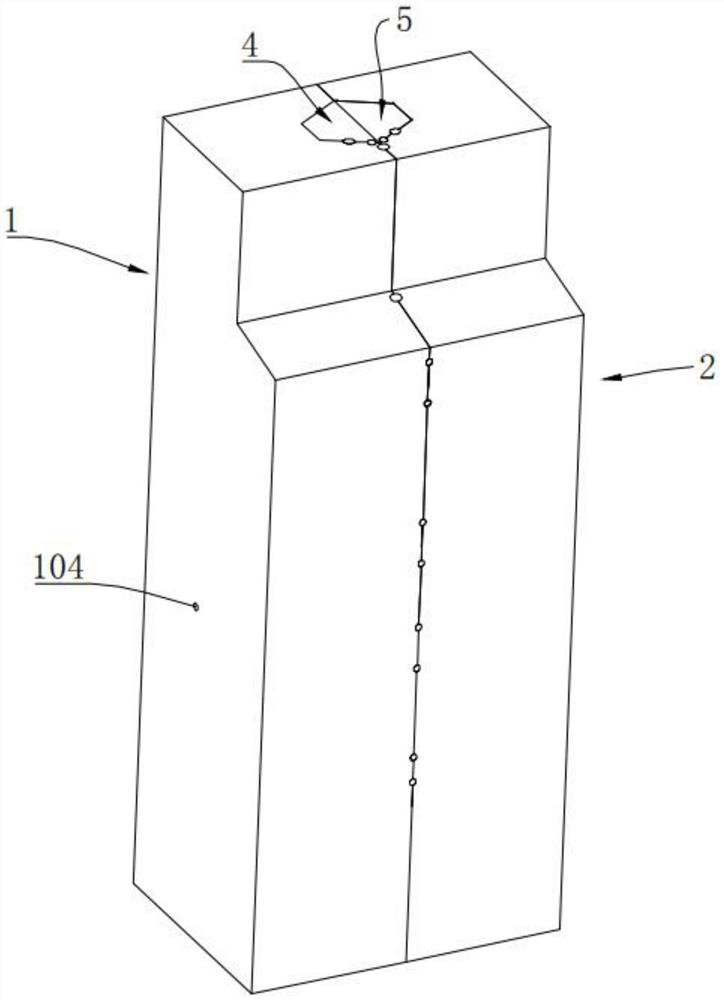

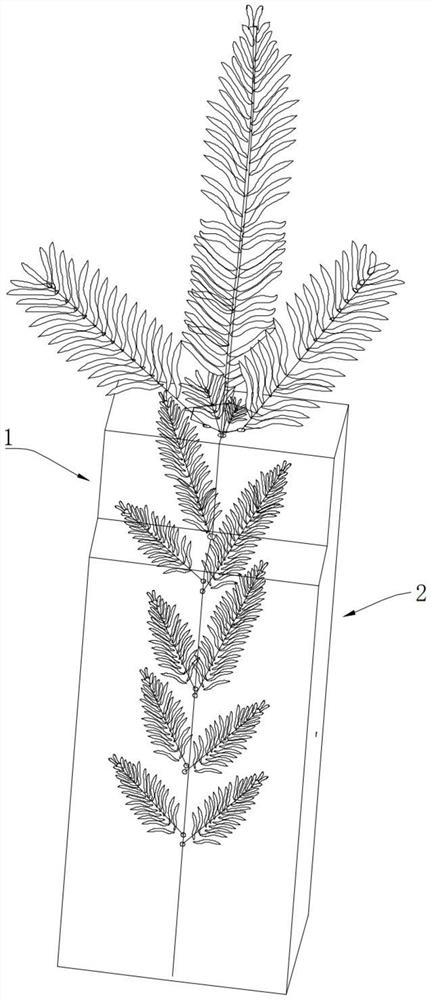

Christmas tree branch integrated molding injection molding process

A branch and one-piece technology, which is applied in the field of Christmas tree branch integral molding injection molding technology, can solve the problems of tree branch falling off and affecting the integrity of Christmas tree branches, and achieve the effect of structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

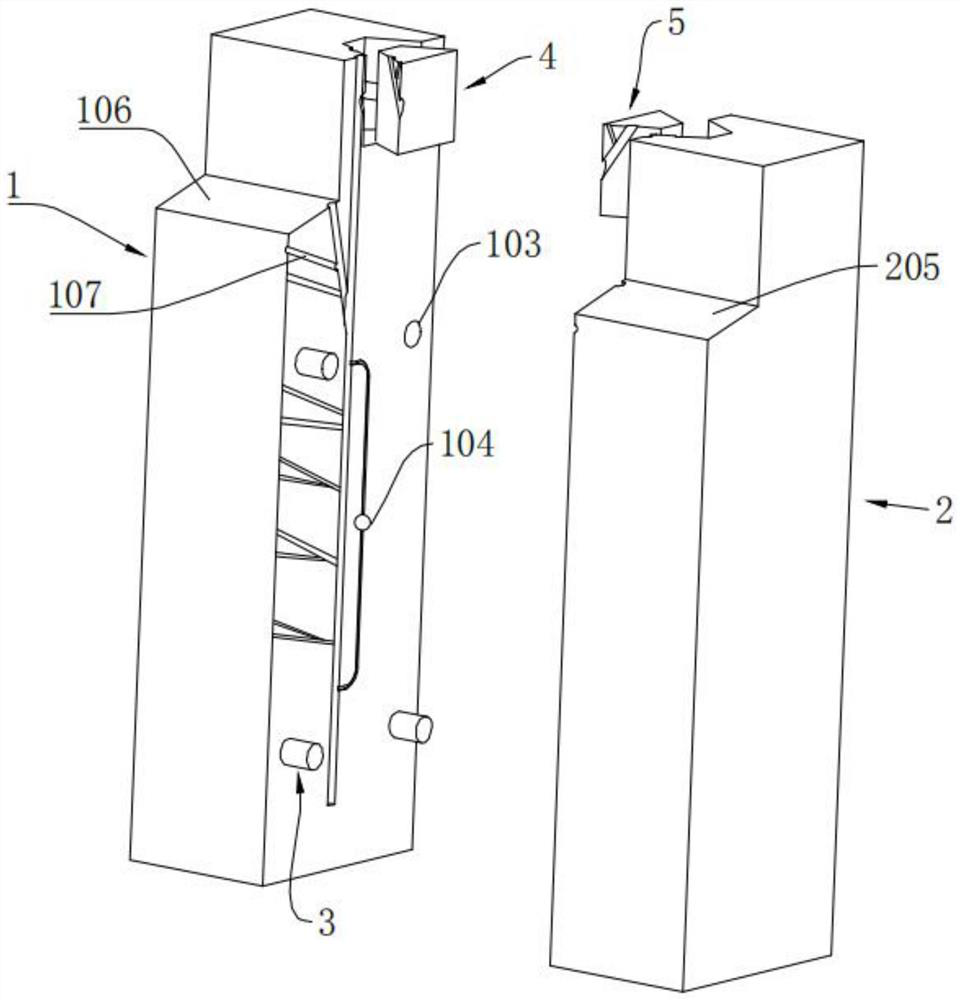

[0026] A number of embodiments of the present invention will be disclosed in the following figures. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are not necessary. In addition, for the sake of simplifying the drawings, some commonly used structures and components will be shown in a simple schematic way in the drawings.

[0027] In the present invention, descriptions such as “first” and “second” are used for description purposes only, and do not refer to the meaning of sequence or sequence, nor are they intended to limit the present invention, but are only used to distinguish The terms describe components or operations only, and should not be understood as indicating or implying their relative importance or implying the number of technical feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com