Graphene heat conduction and heat dissipation film

A heat-dissipating film, graphene technology, applied in the direction of film/flake adhesives, adhesives, etc., can solve the needs of large electronic products, can not meet the problem of heat generation, etc., to speed up thermal conductivity, easy to paste and remove , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

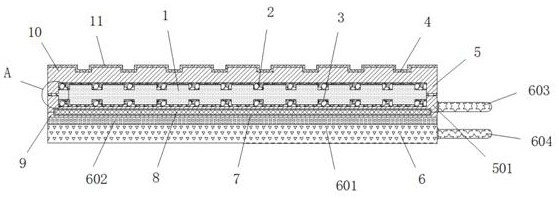

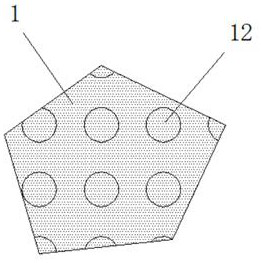

[0035] Example 1: See Figure 1-6 , a graphene heat dissipation film, comprising a graphene layer 1, a lower copper foil layer 9 and an upper copper foil layer 10, the top of the graphene layer 1 is provided with an upper copper foil layer 10, and the bottom end of the graphene layer 1 is provided with The lower copper foil layer 9 is provided with a sealing and anti-expansion structure 5 between the lower copper foil layer 9 and the outside of the upper copper foil layer 10, and the bottom end of the lower copper foil layer 9 is provided with an auxiliary bonding structure 6, and the outside of the graphene layer 1 Equipped with high thermal conductivity and heat dissipation structure;

[0036] see Figure 1-6 , a graphene heat dissipation film also includes a high heat conduction heat dissipation structure, the high heat conduction heat dissipation structure includes an upper groove 12, the upper groove 12 is arranged inside the top of the graphene layer 1, and the inside o...

Embodiment 2

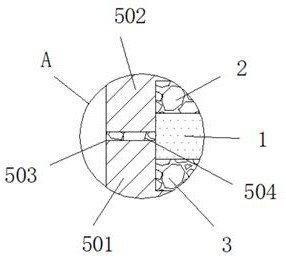

[0040]Embodiment 2: The sealing and anti-expansion structure 5 is composed of a lower sealing frame 501, an upper sealing frame 502, a joint 503 and a sealant 504. The lower sealing frame 501 is fixedly connected to the outside of the top of the lower copper foil layer 9, and the upper sealing frame 502 is fixedly connected. Outside the bottom end of the upper copper foil layer 10, a connection seam 503 is provided between the lower sealing frame 501 and the upper sealing frame 502, and a sealant 504 is provided inside the connection seam 503;

[0041] The lower sealing frame 501 and the upper sealing frame 502 are equal in size, and the lower sealing frame 501 and the upper sealing frame 502 are fixedly connected by a sealant 504;

[0042] The lower sealing frame 501 and the upper sealing frame 502 are on the same vertical plane;

[0043] Specifically, such as figure 1 , image 3 and Figure 4 As shown, in use, the lower sealing frame 501 and the upper sealing frame 502 ca...

Embodiment 3

[0044] Embodiment 3: The auxiliary sticking structure 6 is composed of a release cardboard 601, a high thermal conductivity silica gel 602, a first tear-off piece 603 and a second tear-off piece 604. The high heat conductivity silica gel 602 is arranged at the bottom of the lower copper foil layer 9, and has a high heat conductivity The bottom end of the silica gel 602 is provided with a release cardboard 601, one side of the release cardboard 601 is fixedly connected with a second tear piece 604, and the first tear piece 603 is fixedly connected with one side of the lower copper foil layer 9;

[0045] The length and width between the release cardboard 601 and the high thermal conductivity silica gel 602 are equal, and the length and width of the high thermal conductivity silica gel 602 and the lower copper foil layer 9 are equal;

[0046] Specifically, such as figure 1 As shown, when in use, pull the first tear-off tab 603, and then tear down the second tear-off tab 604, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com