Rubber asphalt mixing device

A rubber asphalt and mixing tank technology, which is applied in the field of asphalt and gravel mixing, can solve problems such as high viscosity of asphalt, accelerated asphalt solidification, and affecting the mixing effect of gravel and asphalt

Active Publication Date: 2022-05-31

重庆九橡化大橡胶科技有限责任公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When the crushed stone is lifted to the mixing device by the lifting mechanism to mix with the molten asphalt, due to the high viscosity of the asphalt, the raw materials between the mixing blades are prone to accumulation during the mixing process, resulting in poor mixing effect of the crushed stone and asphalt , and when the crushed stone at room temperature is mixed with asphalt, it is easy to cause the asphalt to accelerate to solidify, thus affecting the mixing effect of crushed stone and asphalt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

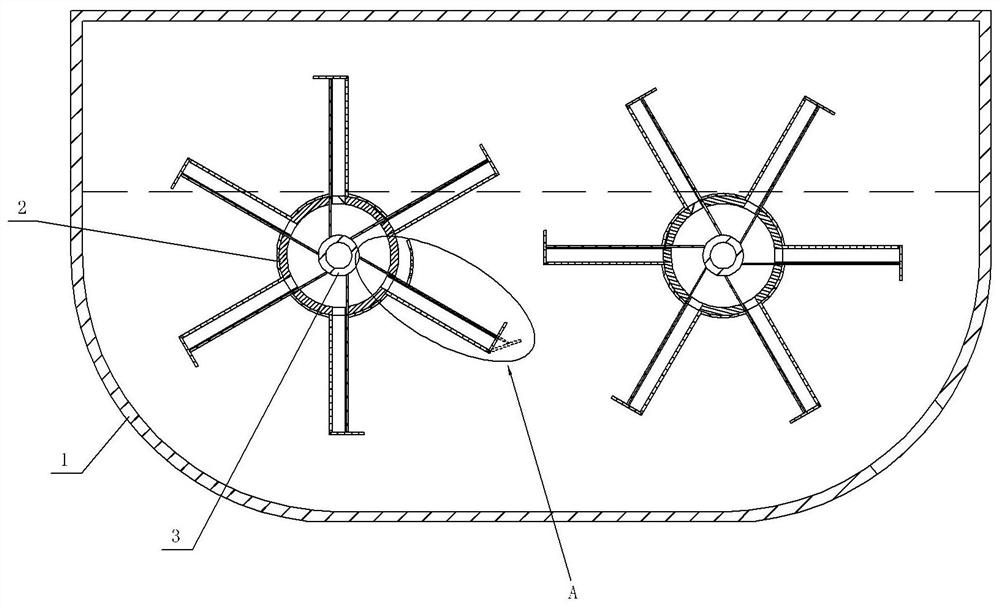

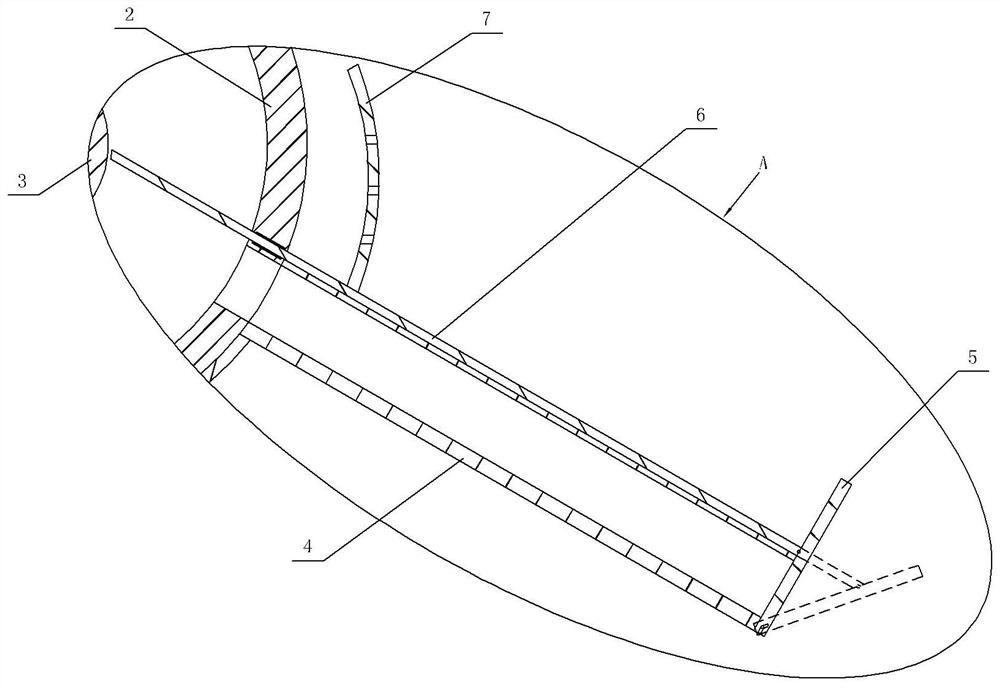

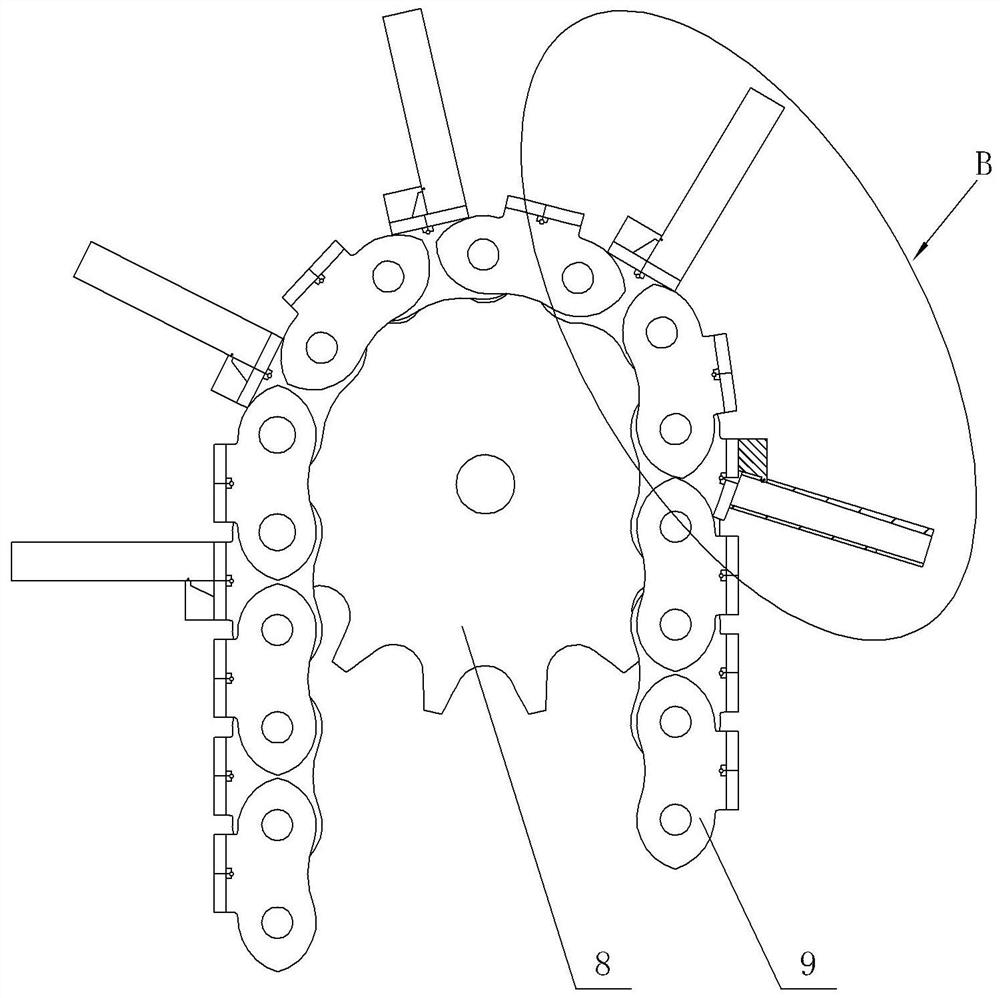

The invention relates to the field of asphalt gravel mixing, in particular to a rubber asphalt mixing device, which includes a mixing box and two mixing units, each mixing unit includes a rotating tube, a heat exchange tube and a number of mixing parts, and each mixing part includes a stirring unit Frame, baffle, slide plate and push plate, one end of the stirring frame is connected with the rotating pipe, the other end of the stirring frame is hinged with the baffle plate, the sliding plate is set on the stirring frame and runs through the rotating pipe, one end of the sliding plate is hinged with the baffle plate, the sliding plate The other end of the push plate can be in contact with the heat exchange tube, and the push plate is fixedly connected with the slide plate. When the technical scheme is adopted, it is beneficial to improve the mixing effect of gravel and asphalt.

Description

Rubber-asphalt mixing device technical field [0001] The present invention relates to the field of asphalt and gravel mixing, in particular to a rubber-asphalt mixing device. Background technique When the crushed stone is lifted to the mixing device by the lifting mechanism to be mixed with the molten asphalt, due to the relatively high viscosity of the asphalt. At the same time, the raw materials between the stirring blades are prone to accumulation during the stirring process, resulting in the mixing of crushed stone and asphalt. The effect is poor, and when the crushed stone at room temperature is mixed with asphalt, it is easy to cause accelerated solidification of the asphalt, thereby affecting the crushed stone and asphalt. Green blend effect. SUMMARY OF THE INVENTION [0003] The object of the present invention is to provide a device that is conducive to improving the mixing effect of crushed stone and asphalt. In order to achieve the above object, technical ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01C19/10

CPCY02A30/30

Inventor 董大伟全永胜

Owner 重庆九橡化大橡胶科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com