Friction damper

A friction damper and friction element technology, applied in the field of washing machines, can solve the problems of loose latch connection, noise interference of friction damper, etc., and achieve the effect of reliable latch connection and ensuring axial prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

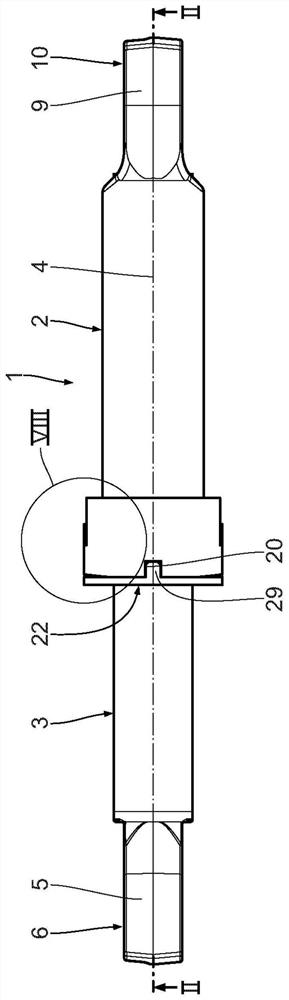

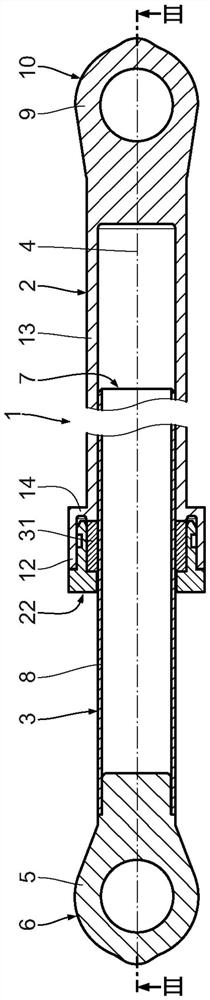

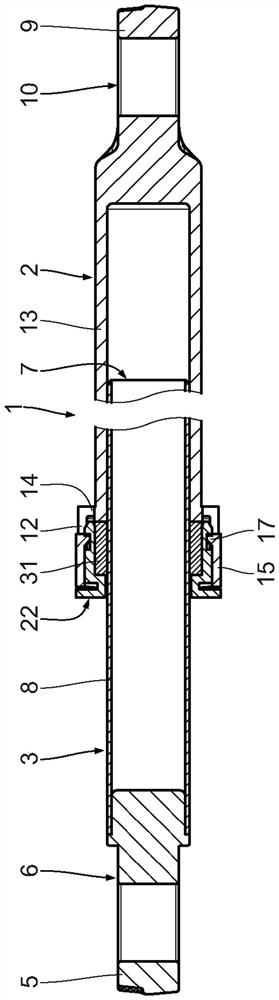

[0032] exist Figure 1 to Figure 3 A friction damper, generally indicated by 1, is used in washing machines to damp vibrations. The friction damper 1 comprises a cylindrical housing 2 and a tubular tappet 3 which is arranged along a longitudinal axis 4 of the housing 2 and is displaceably guided in the housing.

[0033] The tappet 3 comprises a first fixing element 5 by means of which the friction damper 1 can be fixed to an object. The first fastening element 5 is arranged at the free end 6 of the tappet 3 . The free end 6 of the tappet 3 is situated opposite the housing-side end 7 via which the tappet 3 is arranged in the housing 2 .

[0034] The tappet 3 comprises a tappet tube 8 which is in particular made of a lightweight material, in particular a light metal, in particular an aluminum alloy. The tappet 3 can also be made of another material. According to the exemplary embodiment shown, the first fixing element 5 is inserted into the tappet tube 8 at the end face at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com