Air inlet and exhaust device

A technology for exhaust devices and exhaust pipes, which is applied in the direction of valve devices, measuring devices, valve operation/release devices, etc., and can solve problems such as long time, water splashing, and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

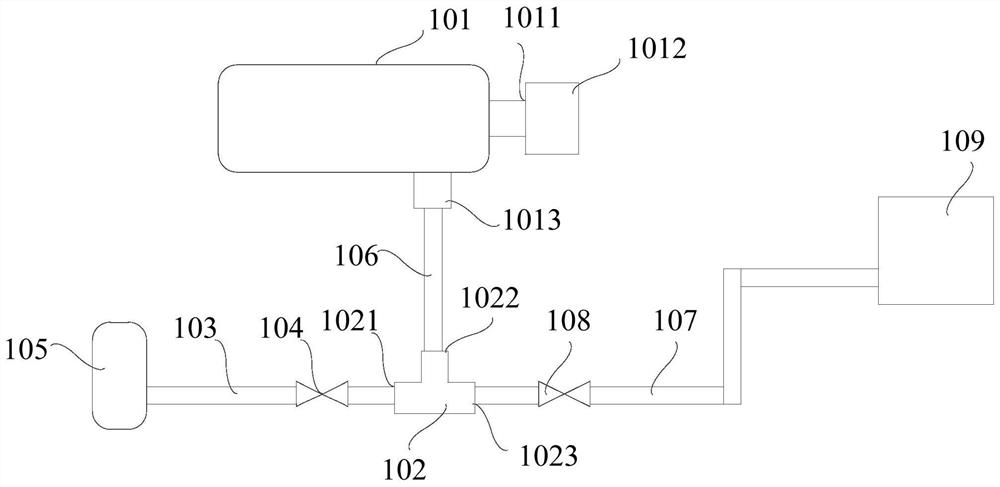

[0048] figure 1 It is a schematic structural diagram of the intake and exhaust device provided in the first embodiment. refer to figure 1 As shown, the air intake and exhaust device for the pressure test operation of the inner tank of the gas heater provided by this embodiment includes a three-way joint 102, an air intake pipe 103, an intermediate pipe 106, an exhaust pipe 107, a muffler tank 109, a first valve 104 and a second valve 108 .

[0049] Specifically, the first interface 1021 of the three-way joint 102 communicates with the gas outlet end of the gas inlet pipe 103, and the gas inlet end of the gas inlet pipe 103 is used to communicate with the gas generating device 105, so that the gas in the gas generating device 105 Transport to the water heater liner 101 for pressure test. A first valve 104 is provided on the intake pipe 103 , and the conduction or closure of the intake pipe 103 is realized by opening or closing the first valve 104 . In practical applications...

Embodiment 2

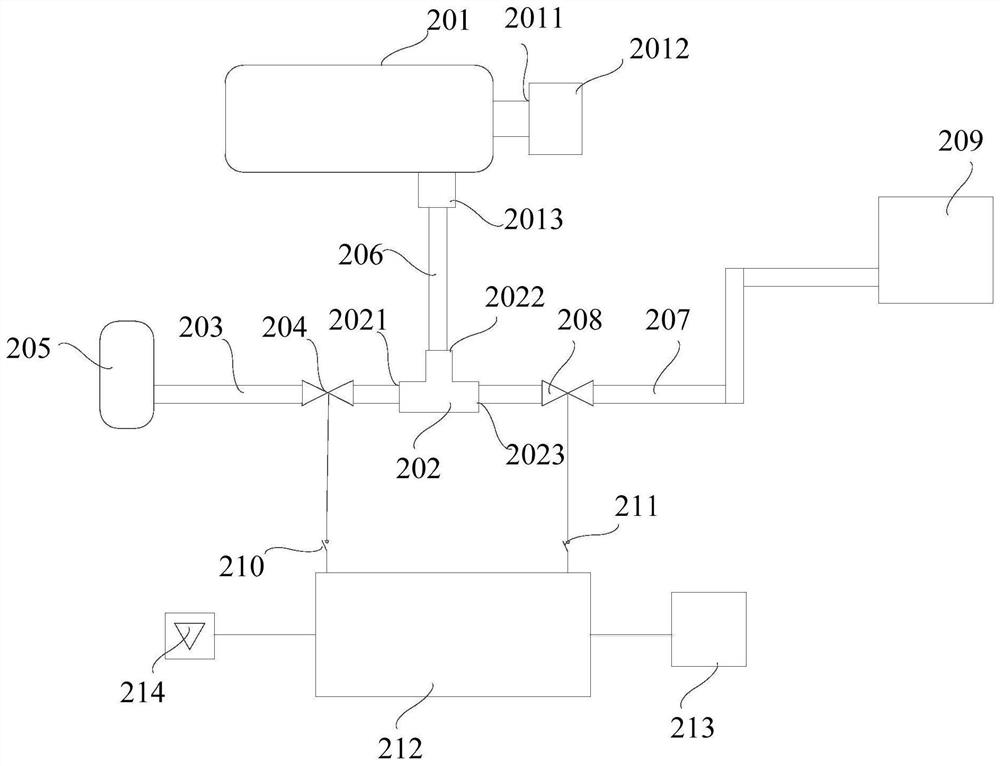

[0078] image 3 It is a schematic structural diagram of the intake and exhaust device provided in the second embodiment. refer to image 3 As shown, the difference between this embodiment and the first embodiment is that the first valve 204 and the second valve 208 are both solenoid valves.

[0079]Specifically, in this embodiment, both the first valve 204 and the second valve 208 are set as electromagnetic valves, which improves the operating efficiency of the first valve 204 and the second valve 208, and further improves the impact of the pressure test process on the intake air. The conduction and closing efficiency of the pipeline 203 and the exhaust pipeline 207 saves the time of air intake, pressure holding and exhaust during the entire pressure test process.

[0080] It should be noted that the solenoid valve used in this embodiment is a common solenoid valve in the prior art, and its specific structure can be referred to the prior art, and will not be repeated here. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com