Refrigeration system and oil supply control method, device and controller thereof

A refrigeration system and oil supply technology, which is used in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of inability to control the amount of oil injection, and the pressure difference between compressor suction and exhaust, so as to improve the initial oil supply temperature, increase the The effect of the oil supply pressure and the requirement to reduce the pressure difference between suction and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

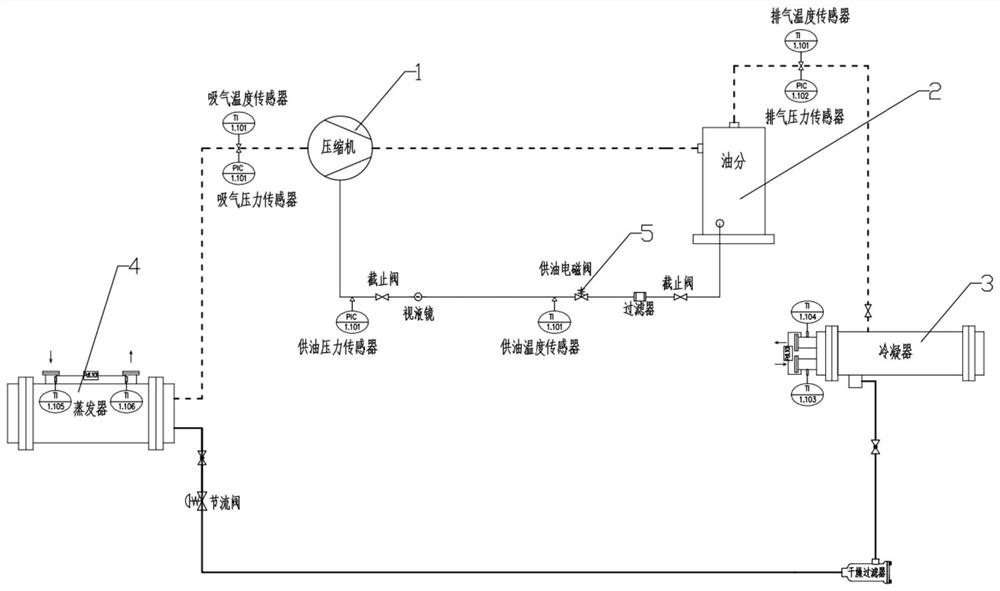

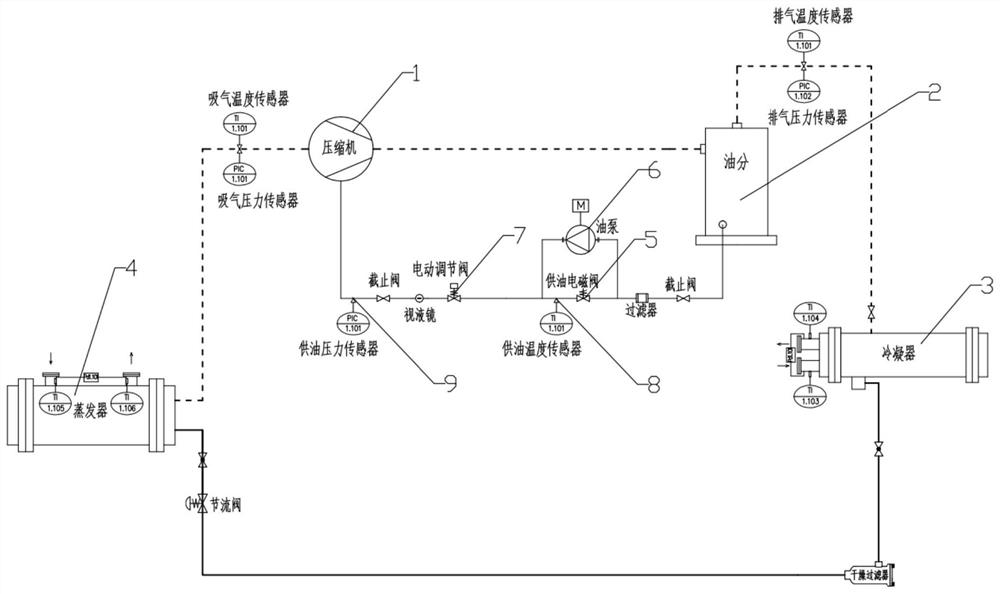

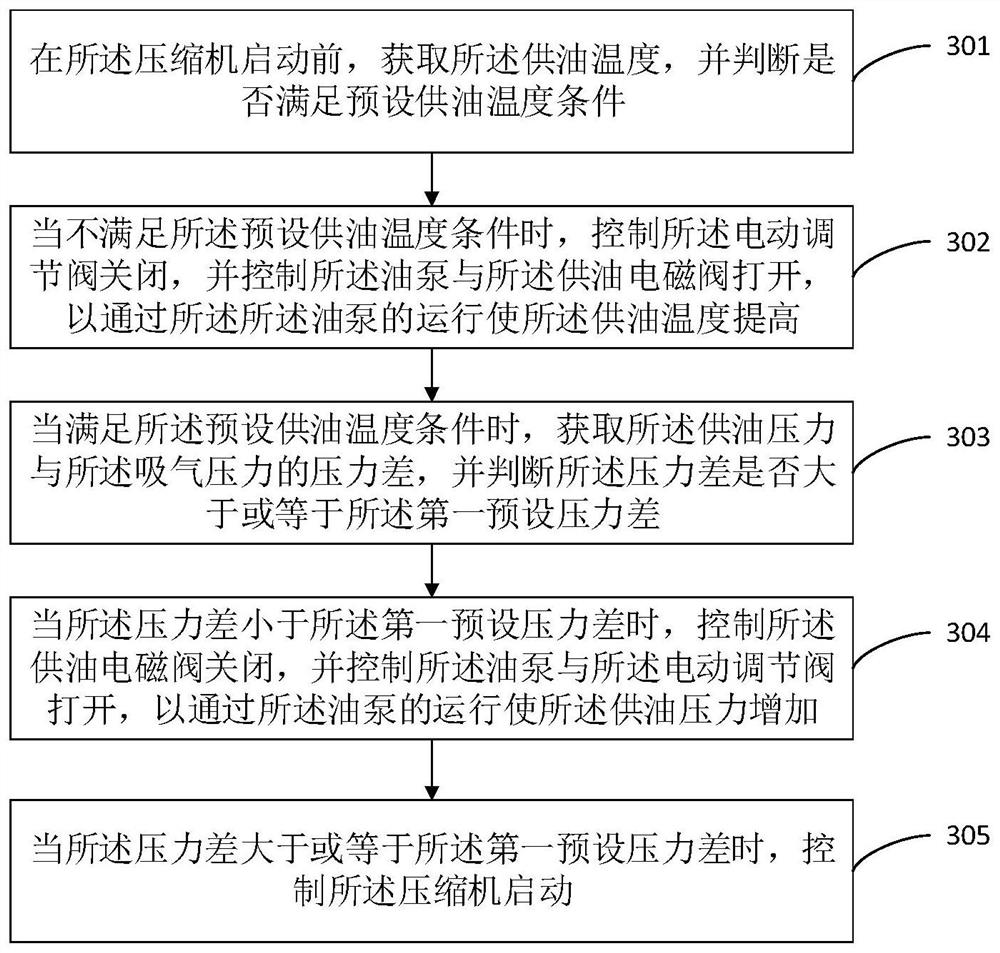

[0079] refer to figure 2 , figure 2 This is a schematic structural diagram of a refrigeration system provided in an embodiment of the present application. like figure 2 shown, the refrigeration system is figure 1 On the basis of the system shown, the oil supply pipeline is also provided with: an oil pump 6 connected in parallel with the oil supply solenoid valve 5, and an electric regulating valve 7 connected in series between the oil supply solenoid valve 5 and the oil supply port of the compressor 1; The inlet of the oil pump 6 is connected to the oil supply pipeline on the outlet side of the oil separator 2; the oil pump 6 is used to increase the initial oil supply temperature and increase the oil supply pressure; the electric regulating valve 7 is used to control the oil flow of the oil supply pipeline. control.

[0080] The oil supply temperature refers to the temperature of the refrigeration oil in the oil supply pipeline before entering the oil supply port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com