Aerosol particle matter size-based collection device and method

An aerosol particle and collection device technology, which is applied in sampling devices, analysis materials, instruments, etc., can solve the problems of high energy consumption, inability to guarantee work efficiency, and inability to popularize industrial applications in the electrostatic collection method, so as to improve the accuracy of experiments, Ensuring accuracy and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

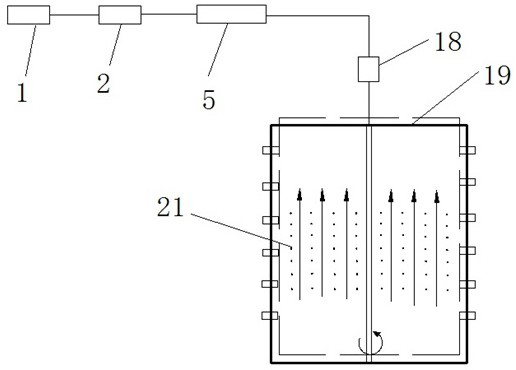

[0040] Such as figure 1 Shown, a kind of aerosol particle matter sub-size collection device, comprises,

[0041] The air intake pipe 1 is arranged horizontally, and the aerosol to be measured is introduced from the air intake pipe 1;

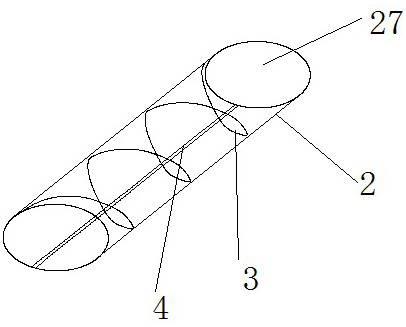

[0042] Such as figure 2 As shown, the dryer 2 is inclined to the plane, the dryer 2 is in a tubular structure, the lower end of the dryer 2 is connected with the air intake pipe 1, and the heating resistance wire 3 for drying the air is arranged inside the dryer 2, and the heating The resistance wire 3 is electrically connected to an external power supply, and the heating resistance wire 3 is arranged spirally around the inner wall of the dryer 2 in the dryer 2. According to the above-mentioned structure, the method of collecting the particles in the dryer 2 is: drying by shaking The device 2 makes the particles attached to the inner wall of the dryer 2 fall into the collection container; further, the inner wall of the dryer 2 is attached wit...

Embodiment 2

[0052] A method for collecting aerosol particles by size, the specific steps are as follows:

[0053] Step 1, the aerosol to be tested (including solid or liquid particles) is introduced into the dryer 2 from the inlet pipe 1;

[0054] Step 2: First, the dryer 2 is preheated for 10 seconds, and then the aerosol to be tested is introduced from the bottom of the dryer 2. The aerosol to be tested is heated by the heating resistance wire 3 to evaporate the water in the liquid particles, and the liquid particles condense after evaporation. Solid particles, the condensed solid particles are attached to the inner wall of the dryer 2, and the dried aerosol is discharged from the top of the dryer 2;

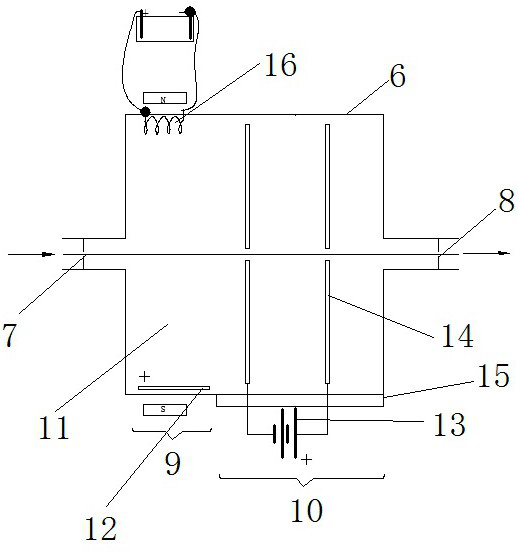

[0055] Step 3, the dried aerosol to be measured is introduced into the ionization device 5, and the ionization area 9 in the ionization device 5 ionizes the particles of the dry aerosol, so that some particles are positively charged, and the dry aerosol enters the particle screening area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com