Visual experiment device for frosting of trace water

An experimental device, a technology for trace water, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problem of not developing the law of sublimation and frosting of trace water vapor, and achieve the effect of real-time measurement of thickness and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

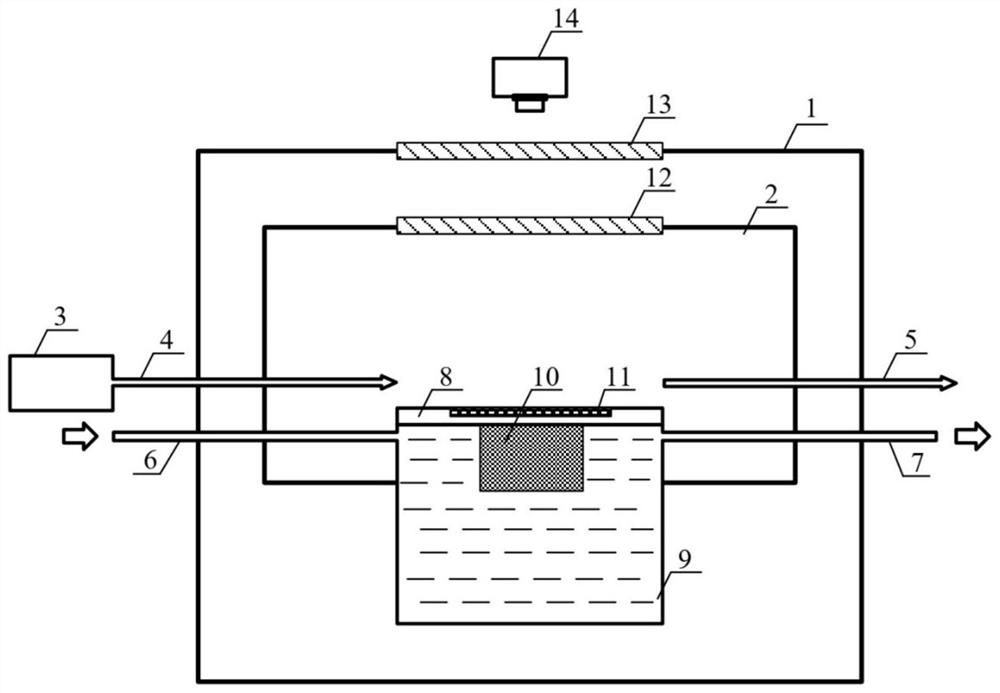

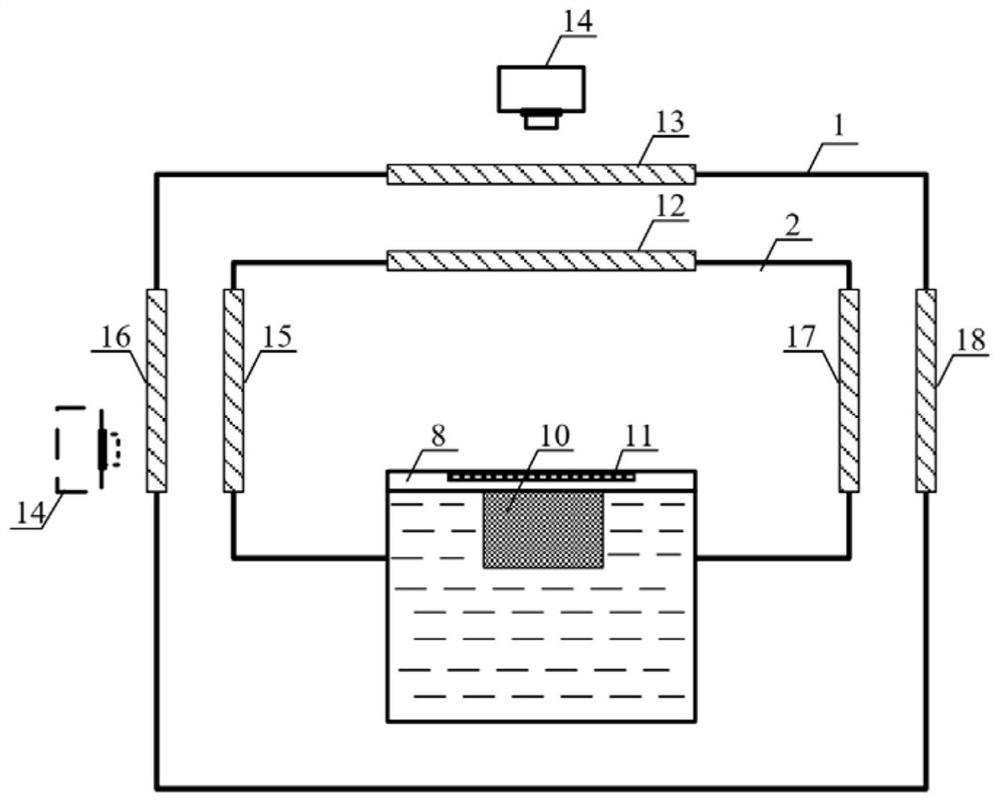

[0031] see figure 1 with figure 2 In this embodiment, the trace water frosting visualization experiment device of this embodiment includes a vacuum box 1 , a constant temperature desublimation frosting unit, a measuring unit and a gas distribution system 3 .

[0032] The constant temperature desublimation frosting unit is arranged in the vacuum chamber 1, including the desublimation chamber 2, the desublimation cold surface 8, the temperature control component 10 and the cold source. In this embodiment, the cold source is the liquid nitrogen pool 9, and the liquid nitrogen pool 9 is set There is a liquid nitrogen inlet pipeline 6 and a nitrogen gas outlet pipeline 7, and the nitrogen gas outlet pipeline 7 is higher than the liquid level of the liquid nitrogen. The two sides of the desublimation chamber 2 are respectively provided with an air inlet pipeline 4 and an air outlet pipeline 5, which respectively pass through the side wall of the vacuum box 1 and connect to the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com