Socket connector, plug connector and connector assembly

A socket connector, plug connector technology, applied in the direction of connecting device parts, connecting, connecting/disconnecting connecting parts, etc., can solve the lack of stability, loose plug and socket connectors, safety hazards and other problems, to achieve the effect of reasonable component structure design, convenient disassembly and assembly, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

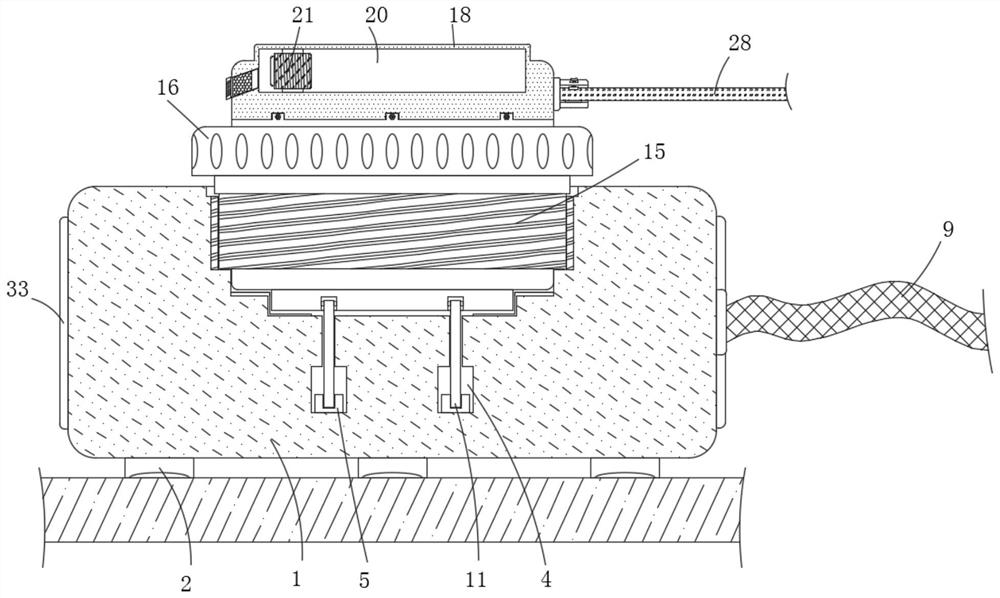

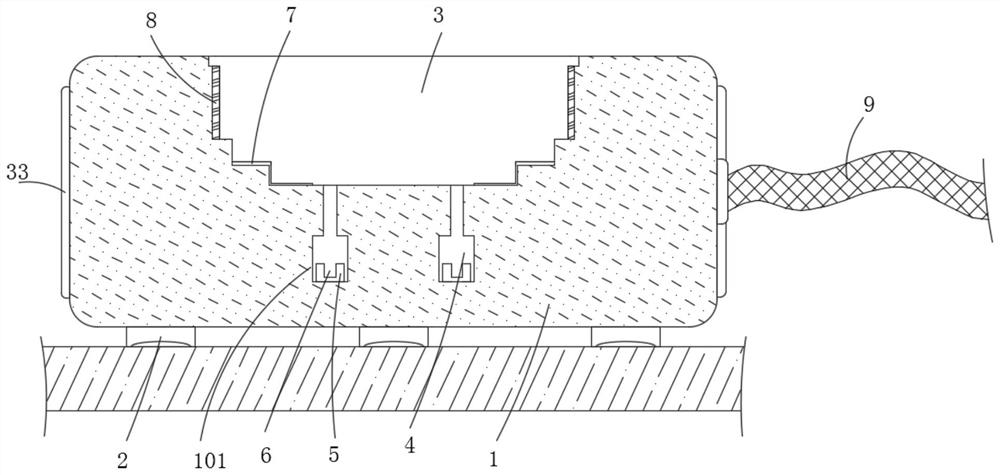

[0024] Embodiment 1, with reference to attached Figure 1-5 , a socket connector provided by the present invention includes a socket housing 1, a foot 2 is installed at the bottom of the socket housing 1, a cylindrical groove 3 is arranged on the side wall of the top of the socket housing 1, and a cylindrical groove 3 The inner wall of the bottom end of the groove 3 is provided with a conductive device 101, and one end of the socket housing 1 is connected to the first power line 9, and the conductive device 101 includes a slot-4 symmetrically arranged on the inner wall of the bottom end of the cylindrical groove 3, and the card slot Groove one 4 is provided with two groups, the bottom end of card groove one 4 inner wall is fixedly provided with conductive block 5, the side wall of conductive block 5 top is provided with card slot 2 6, and the inner wall of cylindrical groove 3 is provided with internal thread 8;

[0025] Further, the two ends of the inner wall of the cylindri...

Embodiment 2

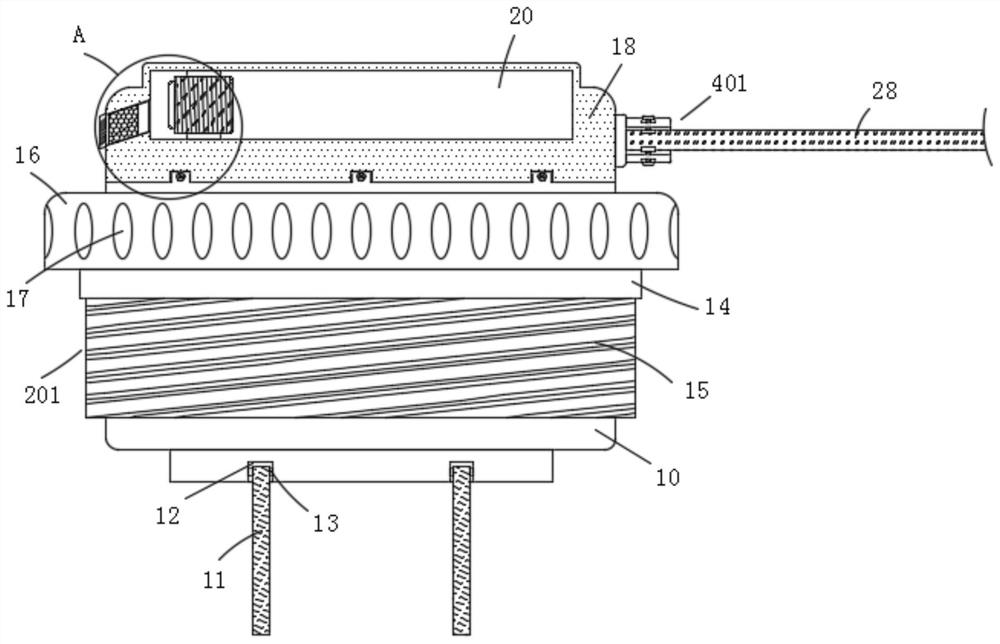

[0033] Embodiment 2, with reference to attached Figure 6 , a plug connector provided by the present invention includes a cylindrical plug body 10, a receiving groove 12 is symmetrically arranged on the bottom side wall of the cylindrical plug body 10, and a conductive rod 11 is rotationally connected to the receiving groove 12 through a damping shaft 13, The main body of the conductive rod 11 is made of bronze material;

[0034] Further, the anti-loosening component 401 also includes a threaded screw 29 symmetrically threaded on the side wall of the fastening outer tube 27. Two sets of screw rods 29 are provided, and one end of the screw rod 29 extending to the inner side of the fastening outer tube 27 passes through a bearing An arc-shaped pressing plate 30 is rotatably connected, and the bottom side wall of the arc-shaped pressing plate 30 is opposed to the outer wall of the second power cord 28 . The top end of the screw rod 29 is fixedly connected with a dial 31 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com