A welding void suppression device and its working method

A technology for suppressing devices and voids, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of not being suitable for large-scale production, harsh and complex implementation conditions, etc., to improve the efficiency of water vapor diffusion, improve safety, and prevent welding voids inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

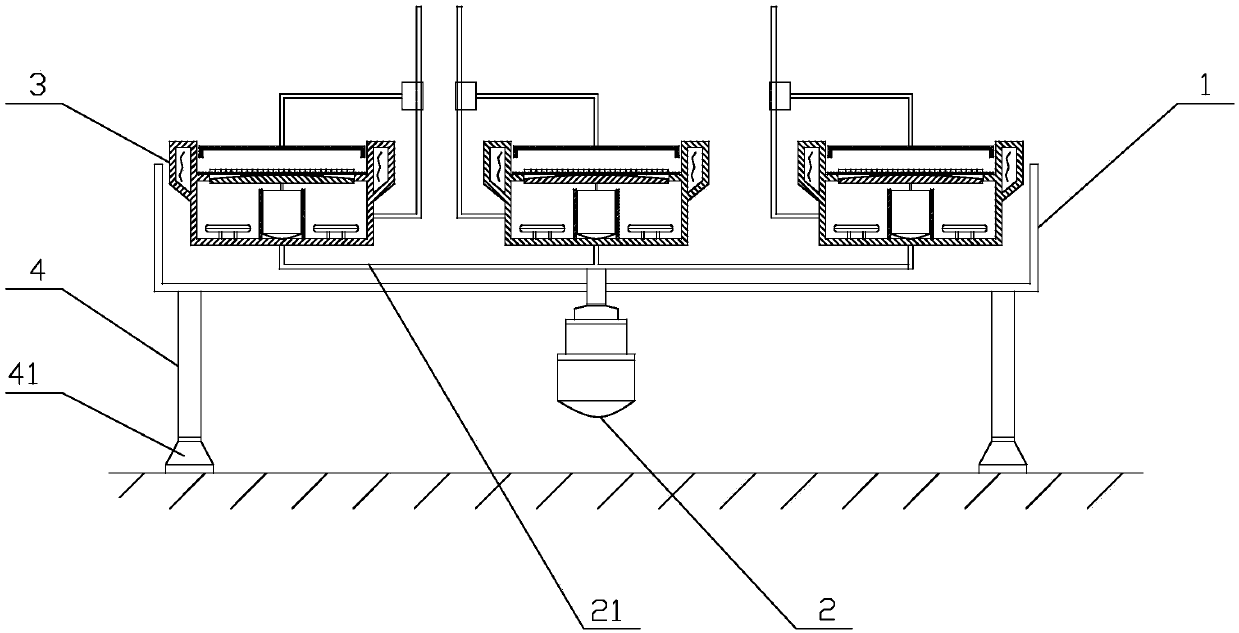

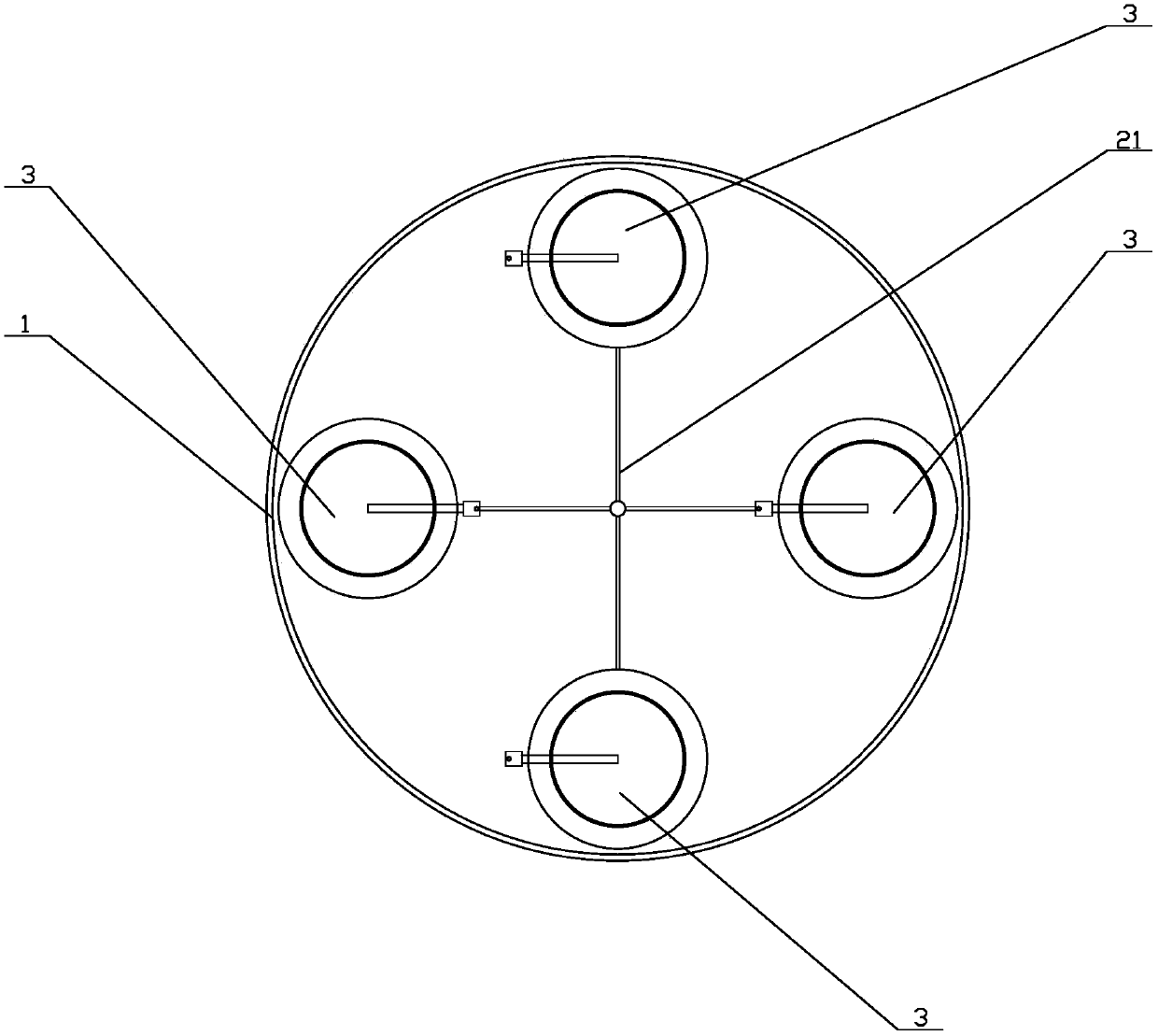

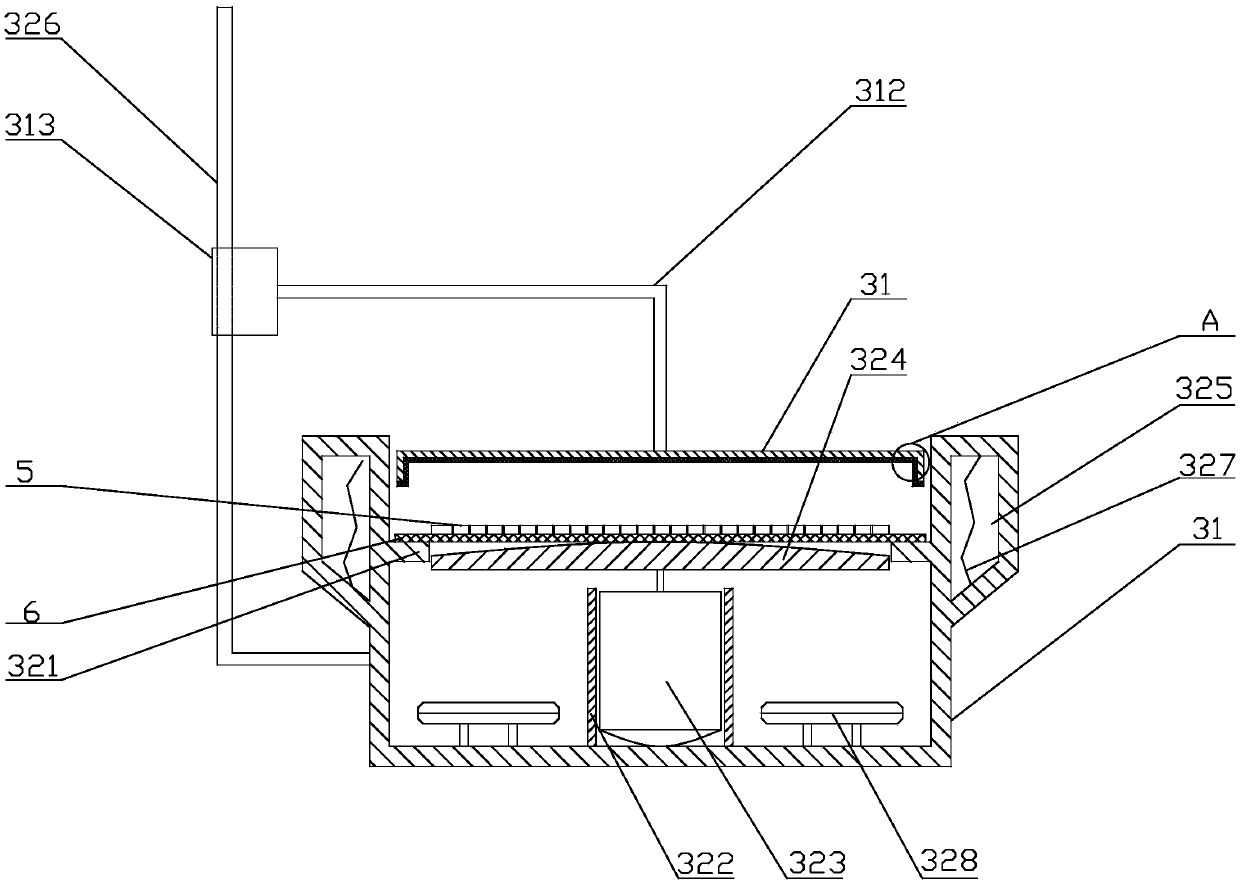

[0033] The present invention as Figure 1-4 As shown, it includes a circular protective bin 1, a stepper motor 2 and four drying bins 3; the center of the protective bin 1 is provided with a circular hole for the shaft of the stepper motor 2 to pass through, and the stepper motor The shaft of 2 passes through the round hole and is fixed on the lower surface of the protective chamber 1; the stepper motor 1 is used to drive the drying chamber to rotate in the protective chamber 2, and the staff can collect and place the wafer 5 (wafer) on the side of the protective chamber 1 Refers to the wafer that has been coated and cut, but the back is still adhered to the blue film), which is convenient and quick, improves work efficiency and reduces work burden. Due to the isolation of the protective compartment, the safety performance is high.

[0034] The four drying bins 3 are respectively equipped with electric heating devices for heating the drying bins 3, thereby heating the wafers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com