Spring for an injection device

A technology of injection device and coil spring, which is applied in the field of manufacturing coil springs, can solve the problems of expensive installation process and cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

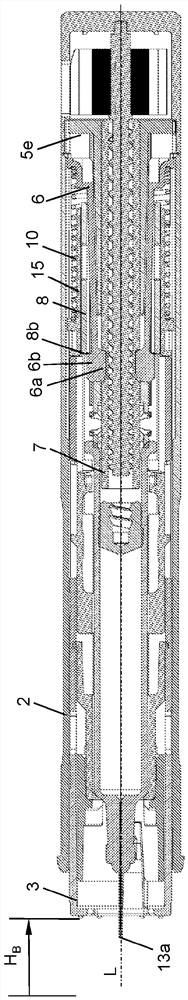

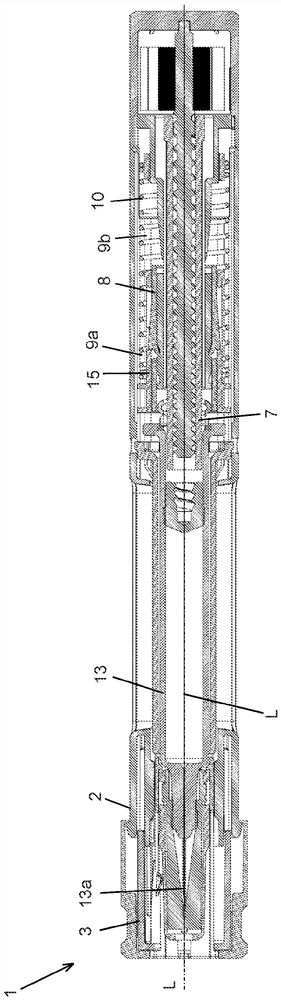

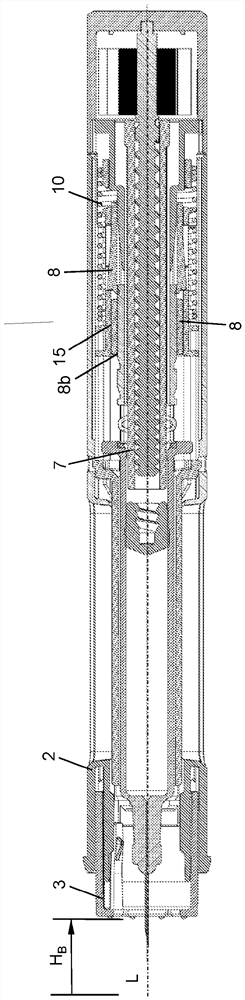

[0040] figure 1 A general perspective view of the helical spring 10 according to the invention is shown. The helical spring 10 is designed as a compression spring and has a winding extending in the axial direction or longitudinal direction of the helical spring 10 with a total of 15 turns. In this case, the helical spring 10 has a length of 114 mm in the unloaded state. It also has an outer diameter of 15 mm. The helical spring 10 is made of a wire having a circular cross section, the wire having a diameter of 0.7 mm. The wires are made of chromel-alloyed spring steel and are also electrically conductive. Such as figure 1 As can be seen in , each of the two outermost turns is connected to each other by point-by-point laser welding.

[0041] The outermost or first turn and the second outermost or second turn of the winding are connected to one another by means of two connection points 20a, 20b, 20c, 20d. The first connection point 20a is approximately 2 mm away from one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com