Method for preparing glycerin zinc

A technology of zinc glycerol and glycerin solution, which is applied in the field of preparation of zinc glycerol, can solve the problems of long reaction time, harsh synthesis conditions, troublesome operation, etc., and achieve the effect of simple and easy synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

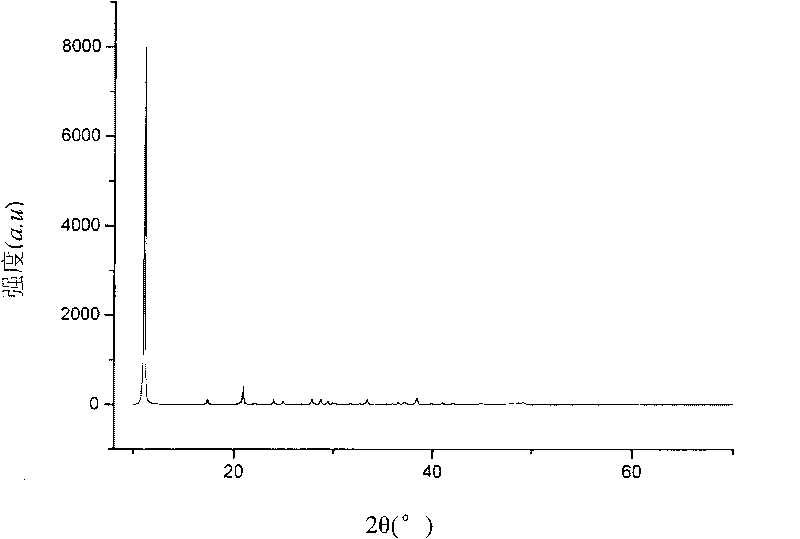

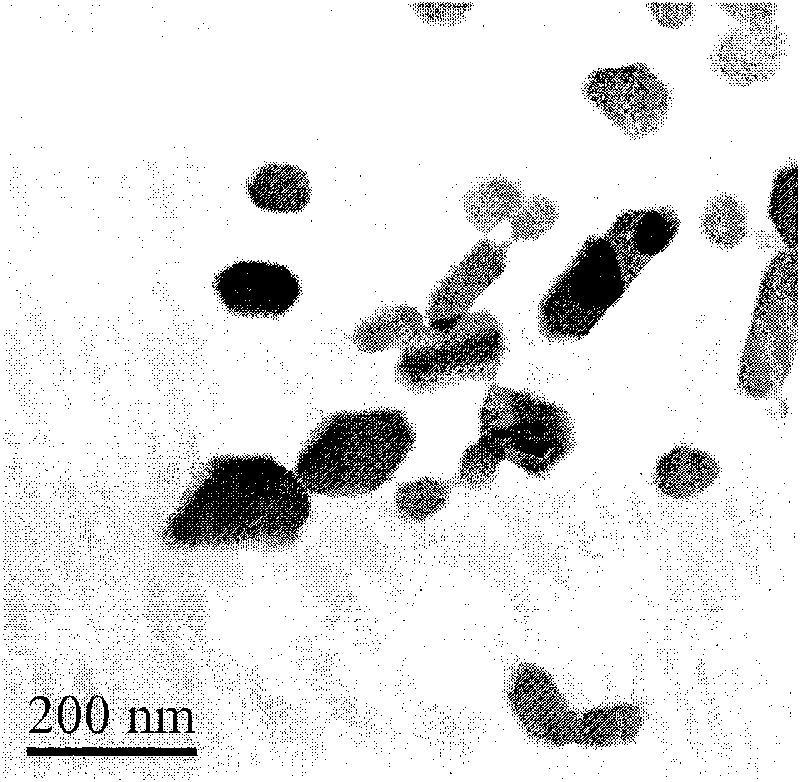

[0015] Example 1, take 0.005mol / L Zn(CH 3 COO) 2 2H 2 O glycerol solution in a 50mL round-bottomed flask, put the round-bottomed flask into a microwave oven, 680W power, and microwave for 3 minutes. Glycerol zinc nanoparticles with a particle diameter of 23 nm were obtained by centrifugation.

example 2

[0016] Example 2, take 0.006mol / L Zn(CH 3 COO) 2 2H 2 O glycerol solution in a 50mL round-bottomed flask, put the round-bottomed flask into a microwave oven, 740W power, and microwave for 4 minutes. Glycerol zinc nanoparticles with a particle size of 29 nm were obtained by centrifugation.

[0017] Example 3, take 0.007mol / L Zn(CH 3 COO) 2 2H 2 O glycerol solution in a 50mL round-bottomed flask, put the round-bottomed flask into a microwave oven, 800W power, and microwave for 4 minutes. Glycerol zinc nanoparticles with a particle size of 37 nm were obtained by centrifugation.

[0018] Example 4, take 0.008mol / L Zn(CH 3 COO) 2 2H 2 O glycerol solution in a 50mL round-bottom flask, put the round-bottom flask into a microwave oven, 800W power, and microwave for 6 minutes. Glycerol zinc nanoparticles with a particle diameter of 48nm were obtained by centrifugation.

[0019] Example 5, take 0.08mol / L Zn(CH 3 COO) 2 2H 2 O glycerol solution in a 50mL round-bottom flask,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com