Cubic copper oxide nanoparticles and its synthesis method and use

A nanoparticle, copper oxide technology, applied in copper oxide/copper hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems of harsh synthesis conditions, high temperature requirements, and difficulty in synthesizing copper oxide nanoparticles with clear shapes. To achieve the effect of simple and easy synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

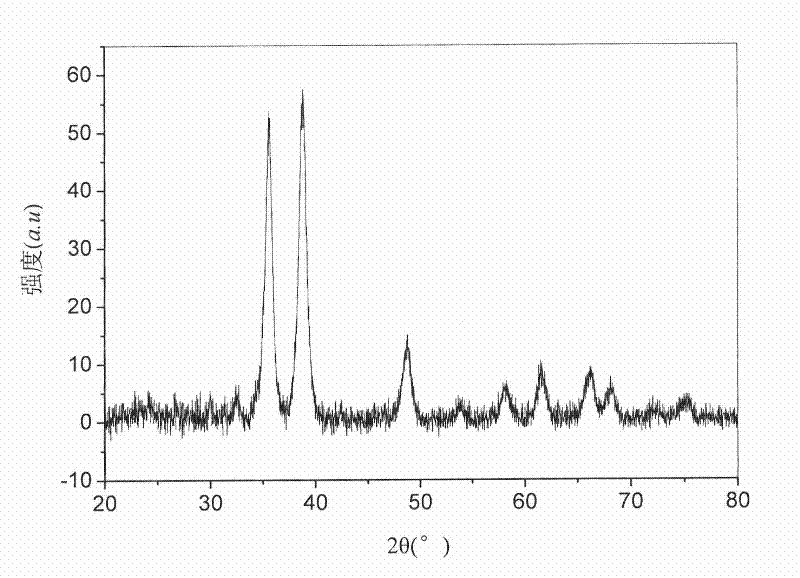

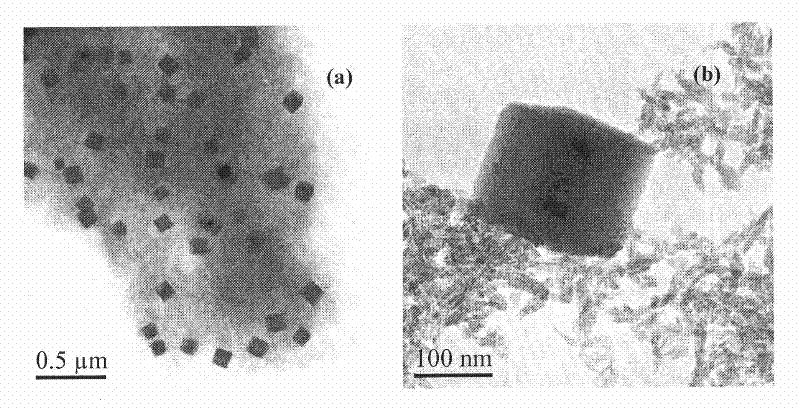

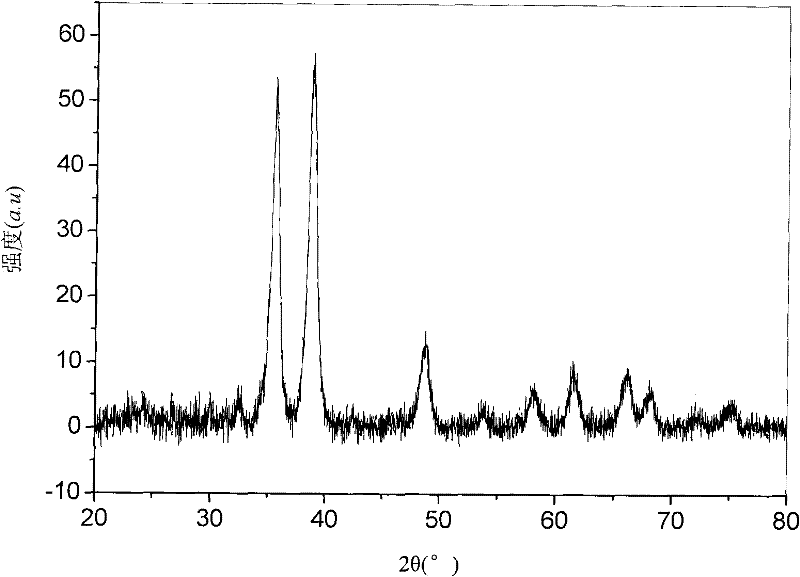

[0017] Example 1. In a 50ml round bottom flask, according to the molar ratio Cu(CH 3 COO) 2 : NaOH:PVP ratio of 1:2:10, add copper acetate aqueous solution, sodium hydroxide triethylene glycol solution, and PVP aqueous solution in turn, keep the total volume at 15ml, mix well to form a homogeneous light blue solution, Then put it in a microwave oven and heat it at 800 watts for 20 seconds while stirring. Stop microwave heating after the color of the solution turns bright dark brown. That is, cubic copper oxide nanoparticles with an average particle diameter of 41 nm were obtained.

[0018] Example two, in a 50ml round bottom flask according to the molar ratio Cu(CH 3 COO) 2 : NaOH:PVP ratio of 1:1:5, add copper acetate aqueous solution, sodium hydroxide triethylene glycol solution, and PVP aqueous solution in turn, keep the total volume at 15ml, mix well to form a homogeneous light blue solution , then put it in the microwave oven, and heat it at 850 watts for 65 seconds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com