Soil crushing and plowing basketry rake

A technology of crushing soil and intermediate position, which is applied in the direction of soil clod crushers, applications, electric vehicles, etc., can solve the problems of time-consuming and manpower, impact, and maintenance, so as to save time and manpower, protect the environment and safety, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

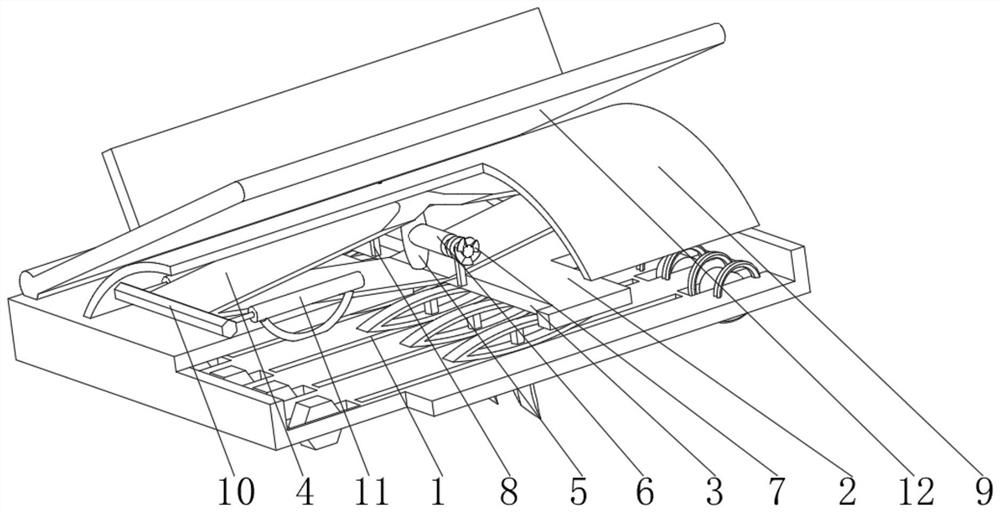

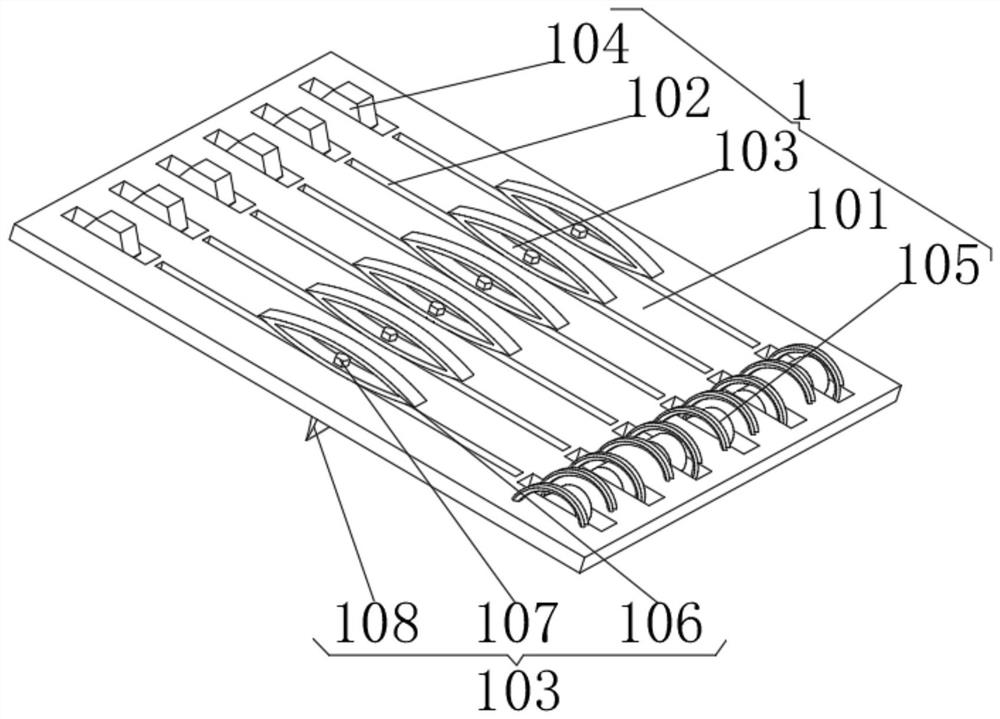

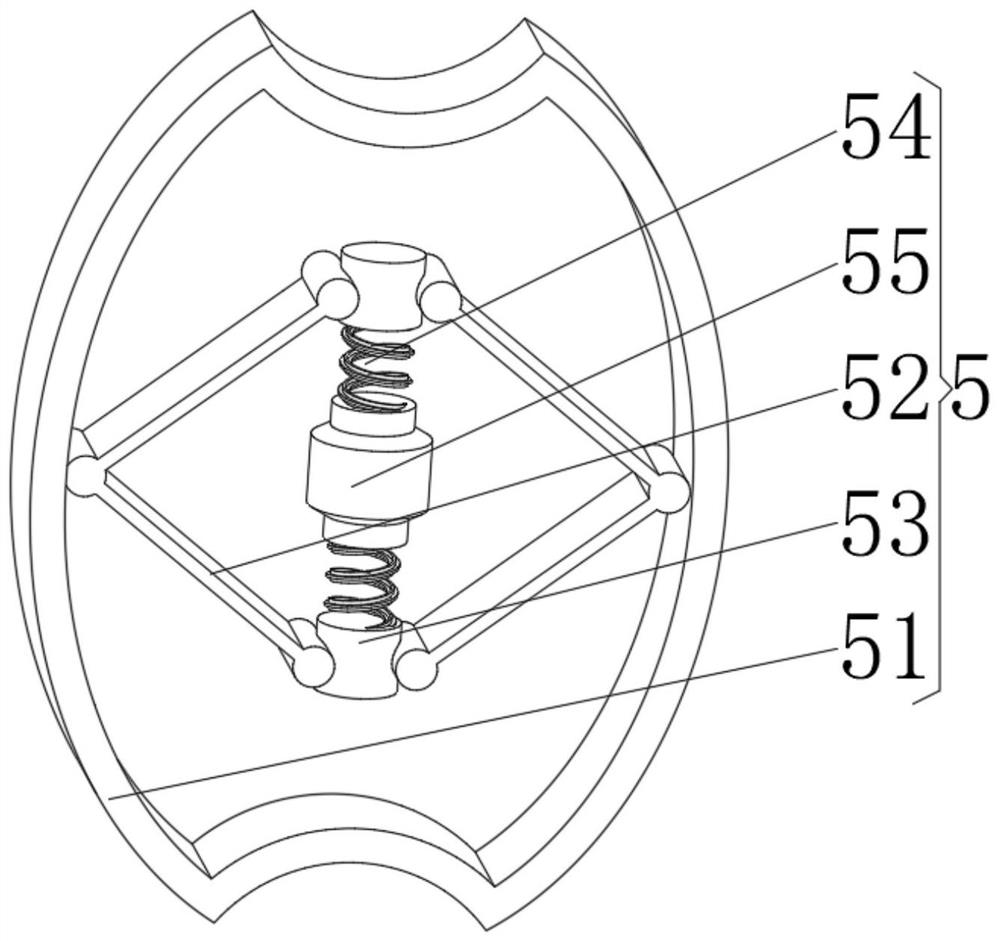

[0038] Such as Figure 1-5As shown, a kind of crushing soil cultivator proposed by the present invention comprises a crushing mechanism 1, and both sides of the top of the crushing mechanism 1 are fixedly connected with a protective frame plate 2, and the middle position of the top of the protective frame plate 2 is provided with a ventilation hole 3 to protect The top of the frame plate 2 is located in the middle of the air hole 3 and is movably connected with a diamond-shaped frame plate 4. The bottom and top of the inner cavity of the diamond-shaped frame plate 4 are fixedly connected with a protection mechanism 5 at the middle position. 6. The end of the power generating mechanism 6 away from the protection mechanism 5 is fixedly connected with the driving blade 7, the top of the protective frame plate 2 is located on the front and back sides of the diamond-shaped frame plate 4, and both sides are fixedly connected with positioning frames 8, and the top of the protective fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com