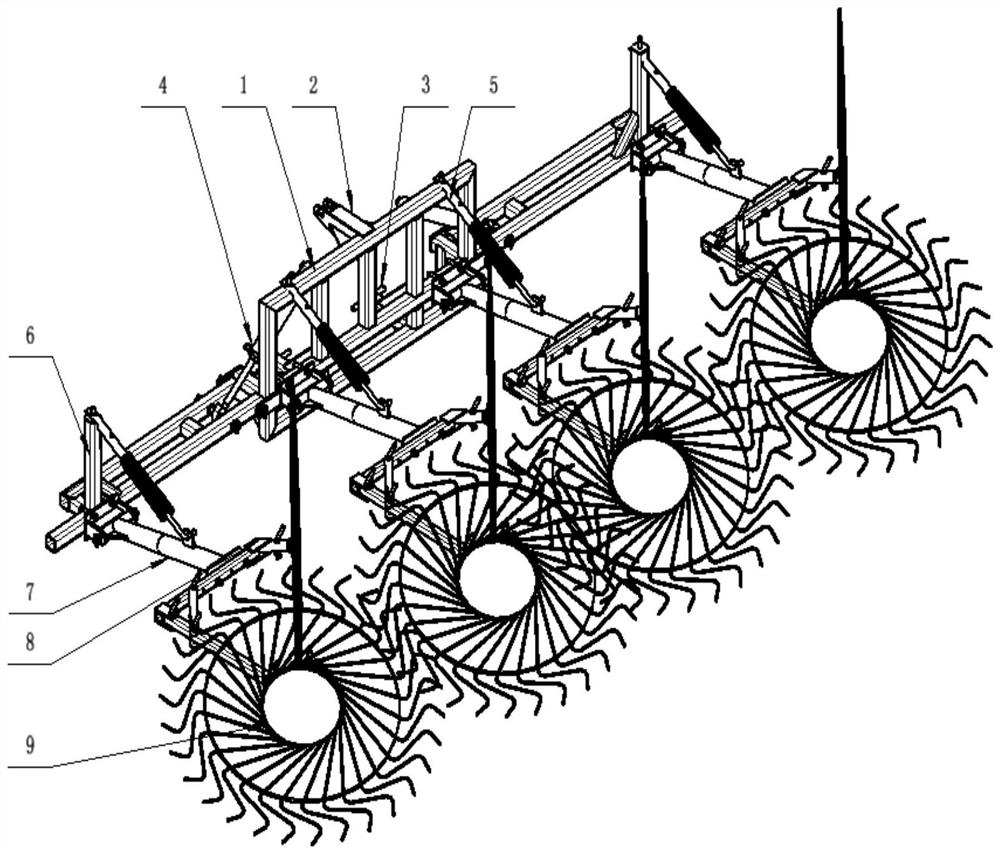

Rear-mounted four-row corn straw strip collecting machine

A corn stalk, post-positioning technology, which is applied in the field of straw returning treatment devices, can solve the problems of lack of black soil protection methods, soil erosion, etc., and achieves the effects of increasing the emergence rate, increasing the ground temperature and having a reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

[0010] Such as figure 1 Shown, the present invention comprises frame 1, is connected with tractor by upper suspension 2 and lower suspension 3. Support arm 7 and limit spring 5 are installed on frame 1 right back, and outer support 6 and extension hydraulic cylinder 4 are installed on both sides of frame 1. On the frame 1 and the outer bracket 6, the support arm 7 is installed through the U-shaped card 10, and the other end of the support arm 7 is installed with the finger plate 9 and the regulator 8. During transportation, the outer support 6 is perpendicular to the frame 1, and the outer support 6 is parallel to the frame 1 during operation. During operation, the forward direction and speed of the patent of the present invention are kept consistent with the tractor, and the finger plate 9 rubs against the straw-covered ground surface, causing the finger plate 9 to rotate, and the linear speed of rotation is consistent with the forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com