Controlled cooling device and method for reducing core-surface temperature difference and surface hardness of large-specification bar

A surface hardness and large-scale technology, applied in temperature control, workpiece surface treatment equipment, cooling bed, etc., can solve problems affecting the rolling line rhythm and reducing rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

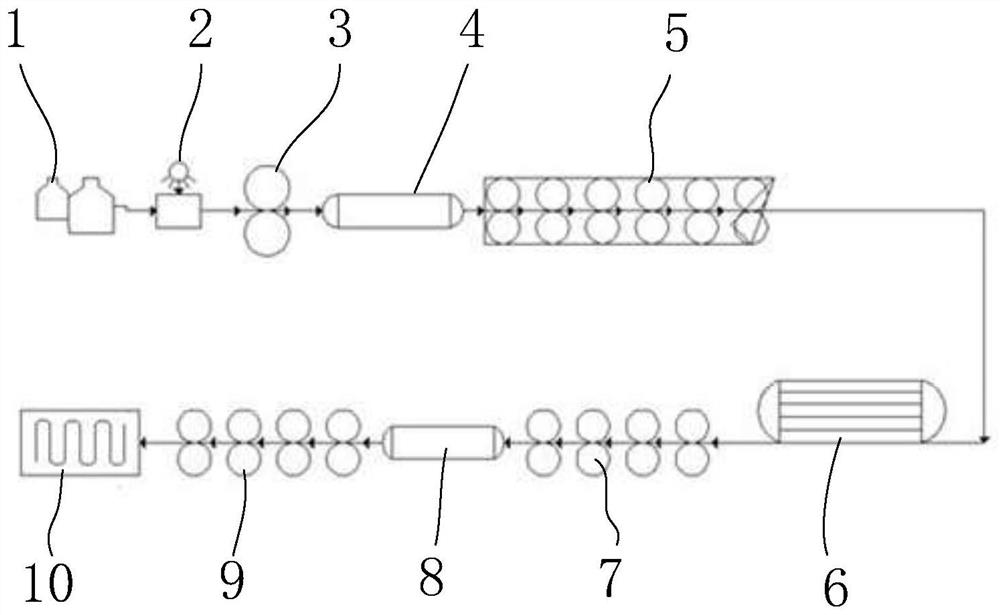

[0023] Example 1: The controlled rolling bar is 42CrMoA, the bar specification is Φ90mm, and the continuous casting slab size used is 320*480mm.

[0024] The billet is heated in the heating furnace 1, and the furnace temperature is 1130°C. After descaling 2 by high-pressure water, it enters the reciprocating rough rolling unit 3 for rough rolling. After rough rolling, after the head and tail are cut off by the first hot saw 4, when the temperature reaches 1050° C., the rolled piece enters the horizontal and vertical alternating middle rolling unit 5 for rolling. After the intermediate rolling is completed, the rolled piece moves laterally to the marshalling stand 6 for waiting for temperature treatment. When the temperature of the rolled piece reaches 910°C, it is sent to the output roller table by the steel transfer trolley. The rolled piece passes through the pre-finishing unit 7 without pre-finishing. After the head and tail are cut off by the second hot saw 8, the rolled...

Embodiment 2

[0026] Example 2: The controlled rolling bar is SAE4137H, the bar specification is Φ130mm, and the continuous casting slab size used is 320*480mm.

[0027]The billet is heated in the heating furnace 1, and the furnace temperature is 1130°C. After descaling 2 by high-pressure water, it enters the reciprocating rough rolling unit 3 for rough rolling. After rough rolling, the first hot saw 4 cuts off the head and tail, the temperature of the rolled piece reaches 1050°C, and the rolled piece enters the horizontal and vertical alternating intermediate rolling unit 5 for final rolling to produce the finished product. After the rolling is completed, the rolled piece moves laterally to the marshalling stand 6 for waiting for temperature treatment. When the temperature of the rolled piece reaches 820°C, the rolled piece is sent back to the rolling roller table by the steel transfer trolley. The rolled piece is empty through the pre-finishing rolling group 7 without pre-finishing, and...

Embodiment 3

[0029] Example 3: The controlled rolling bar is 20CrMoTiH, the bar size is Φ60mm, and the continuous casting slab size used is 320*480mm.

[0030] The intermediate billet is heated in the heating furnace 1, and the furnace temperature is 1130°C. After dephosphorization 2 by high-pressure water, it enters the reciprocating rough rolling unit 3 for rough rolling. After rough rolling, the first hot saw 4 cuts off the head and tail, and the temperature of the rolled piece reaches 1050° C., and the rolled piece enters the alternate intermediate rolling unit 5 for intermediate rolling. After the intermediate rolling is completed, the rolled piece moves laterally to the marshalling stand 6 for waiting for temperature treatment. When the temperature of the rolled piece reaches 920°C, the rolled piece is just sent back to the rolling roller table by the cooling roller table. When the temperature reaches 910°C, the rolled piece is sent to the pre-finish rolling unit 7 for pre-finish r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com