Automatic grinding equipment for fan gear

A technology for gears and fans, applied in the field of automatic grinding equipment for fan gears, can solve the problems of low efficiency, high labor intensity, inaccurate grinding and chamfering accuracy, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

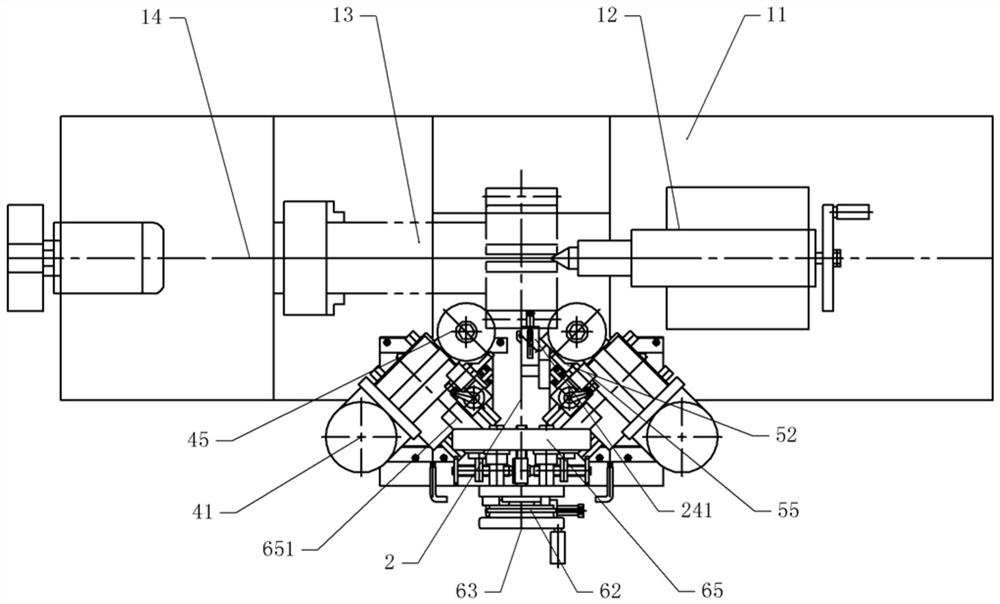

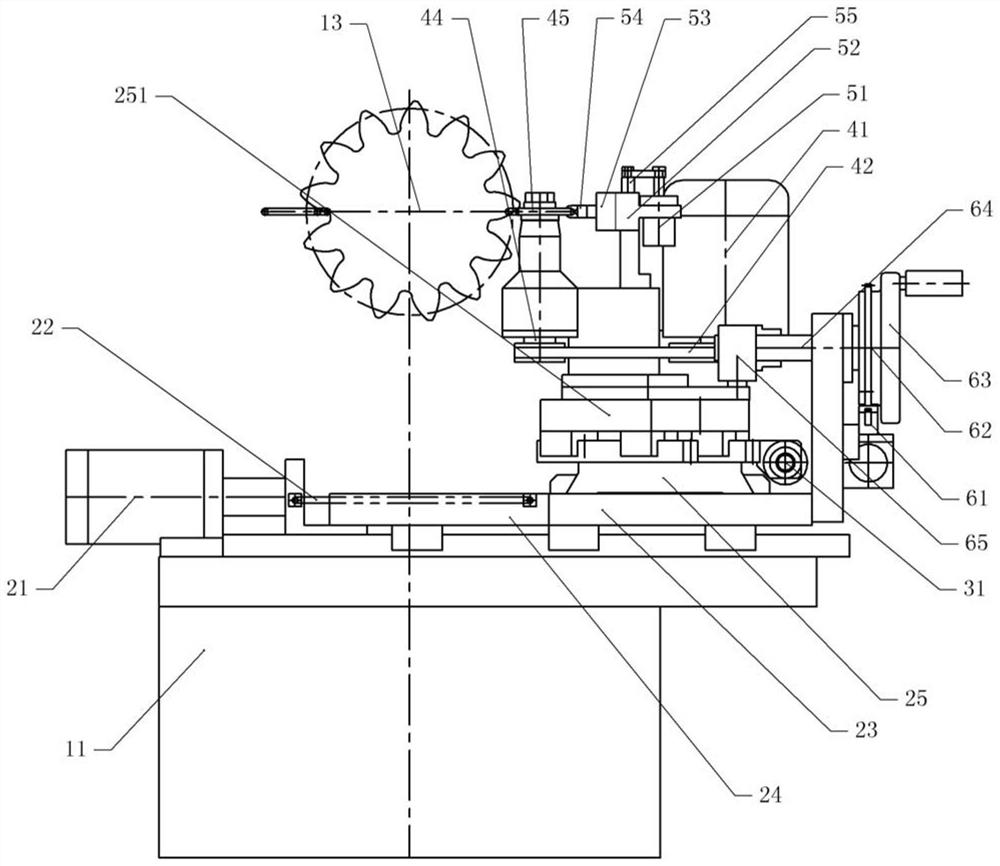

[0033] Basic as attached figure 1 to attach Figure 4 Shown: an automatic grinding equipment for fan gears, installed on the existing lathe 11, one side of the existing lathe 11 is equipped with a rotatable clamp 14, and the other is equipped with a thimble sleeve 12, and the cylindrical cam that needs to be polished Clamped between the clamp 14 and the thimble sleeve 12 .

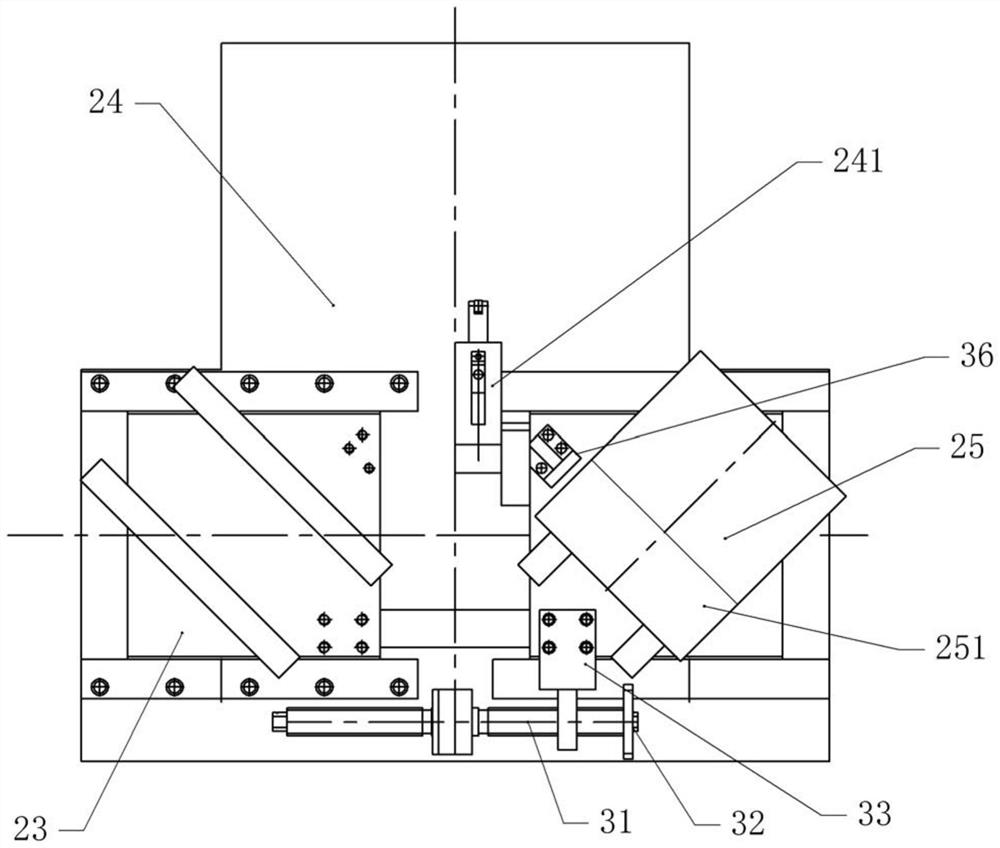

[0034] The automatic grinding equipment for fan gears includes an electric control cylinder 21 installed longitudinally on the lathe 11 and a base 2 that is horizontally slidingly connected to the lathe 11. Bolts on the base 2 are fixed with a profiling seat 24 that is horizontally slidably connected to the lathe 11. Spring 22 is installed between the output shaft of seat 24 and electric control cylinder 21, and one end of spring 22 is welded on the profiling seat 24, and the other end of spring 22 is welded on the output shaft of electric control cylinder 21. A profiling wheel 241 is installed on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com