Threading and cutting device

A cutting device and threading technology, applied in transportation and packaging, metal processing, sending objects, etc., can solve problems such as low production efficiency, low precision, and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

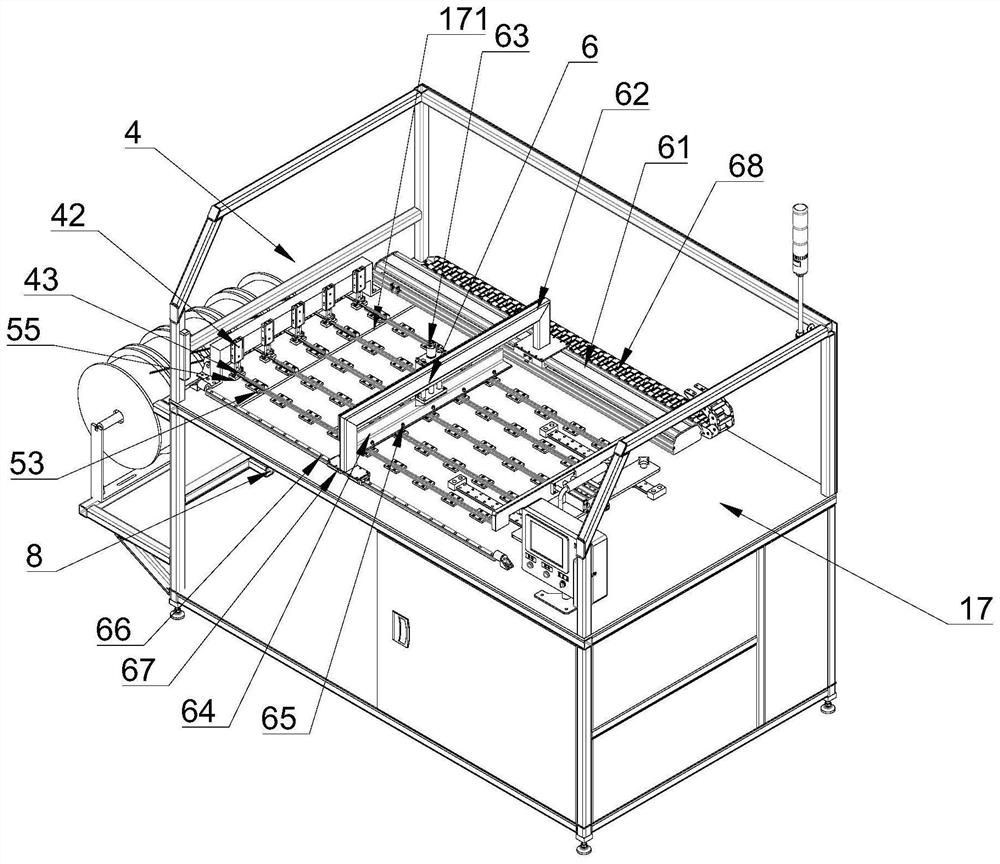

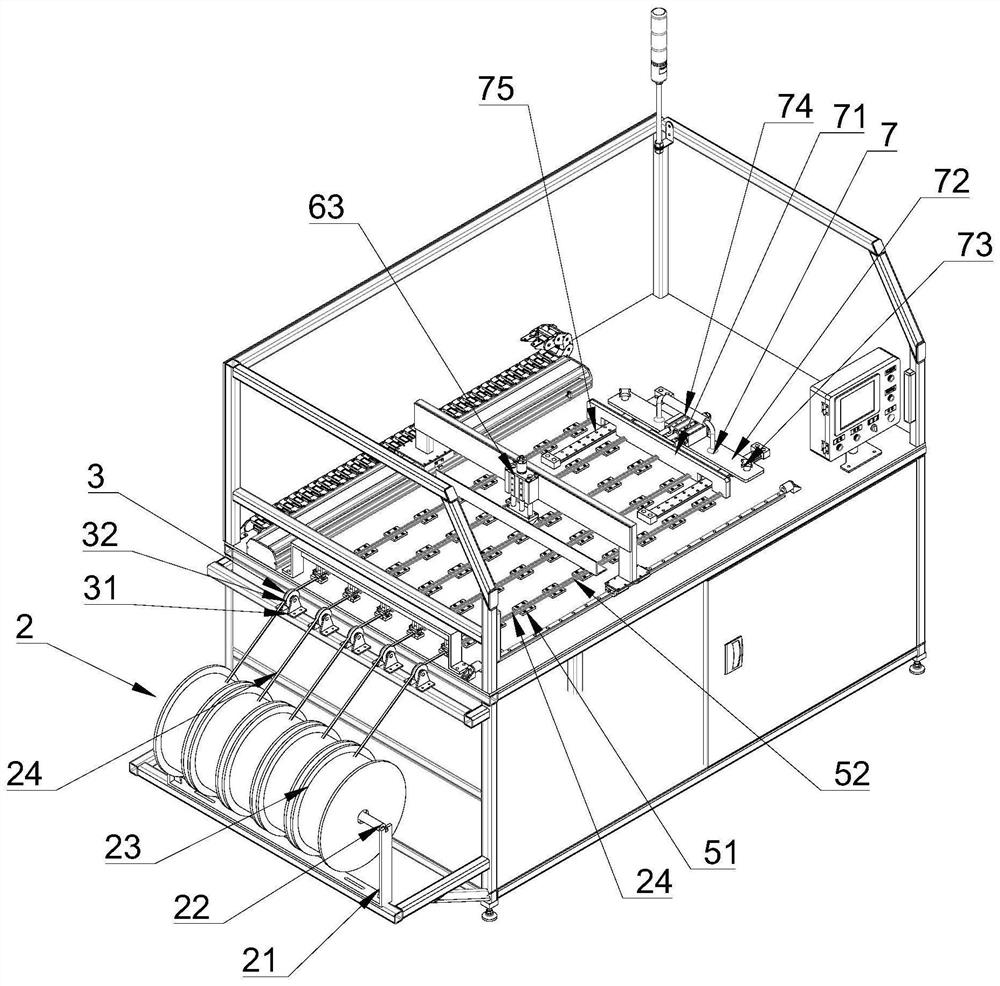

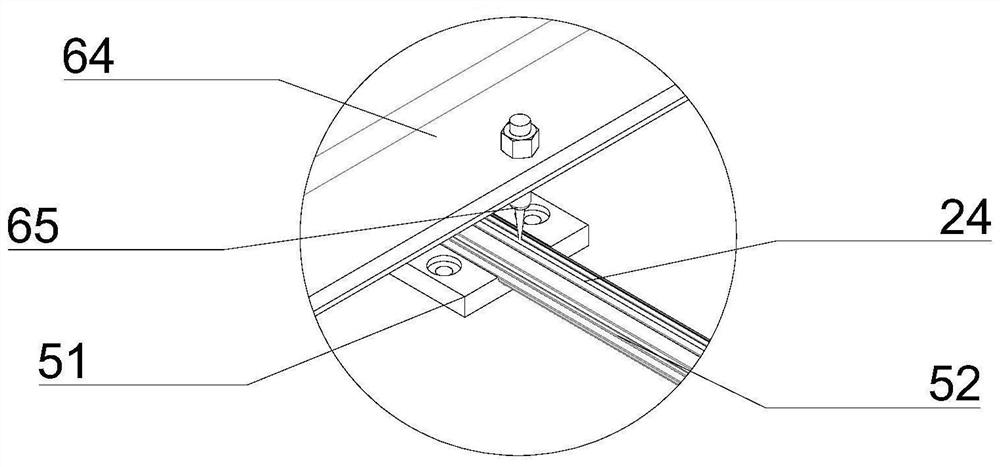

[0048] like Figure 1 to Figure 8 As shown, the threading and cutting device of the present invention is used to thread the first material 24 onto the second material 52, including: a working platform 17; a fixed structure, which is arranged on the working platform 17, and the second material 52 is detachably arranged on the fixed structure. When passing the first material 24 on the second material 52, the worker places the second material 52 on the fixed structure manually or by means of a mechanical arm. above, and use the fixed structure to limit the multi-degrees of freedom of the second material 52, so as to ensure that the second material 52 will not move relatively during the passing process of the first material 24; the passing structure is set on the working platform 17 , and the threading structure can drive the first material 24 to move freely along the preset t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com