Automatic cloth unbundling and unfolding device

A cloth, automatic technology, applied in the field of automation, can solve the problems of inability to unpack the rope, low work efficiency, time-consuming and labor-intensive, etc., and achieve the effects of saving labor, improving production efficiency, and saving resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

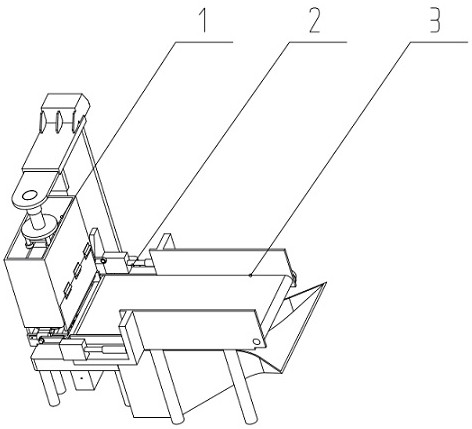

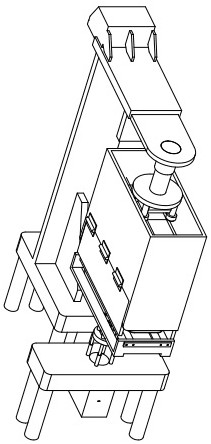

[0022] Examples such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a cloth automatic unbundling and unfolding device includes an unpacking rope device 1, a cloth unpacking device 2, a cloth conveying device 3 and a control device. The packing rope device 1 is fixedly installed at the end of the cloth conveying device 3;

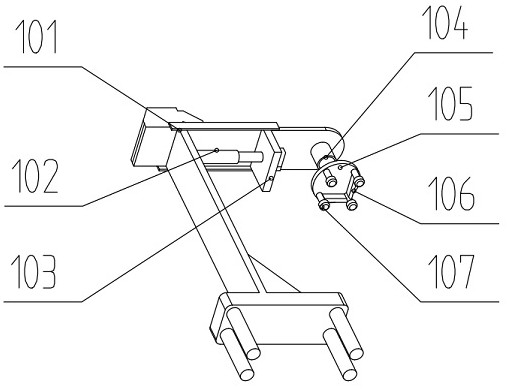

[0023] Unpacking rope device 1, including cutting off fixed frame 101, first cylinder 102, cutting off sliding frame 103, second cylinder 104, first disc 105, cutting knife 106, first rubber claw 107, case shell 108, hinge 109 , door 110, roller 111 and packing rope collecting device;

[0024] The packing rope collection device comprises: the second rubber claw 112, the first claw hand 113, the first motor 114, the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com