Manufacturing method of landscape intercepting well body

A production method and technology of intercepting wells, which are applied in the fields of manufacturing tools, strengthening molding, climate change adaptation, etc., can solve the problems of heavy installation workload, high cost, and high requirements for printing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] See Figure 1-13 As shown, the manufacturing method of the landscape interception well body of the present invention includes the following steps.

[0034] (1) Print well body components: use concrete 3D to print out a plurality of first well body components 1 for splicing, a plurality of second well body components 2 and well bottom components 3, and the concrete can be made of not less than C30 concrete Strong printing material.

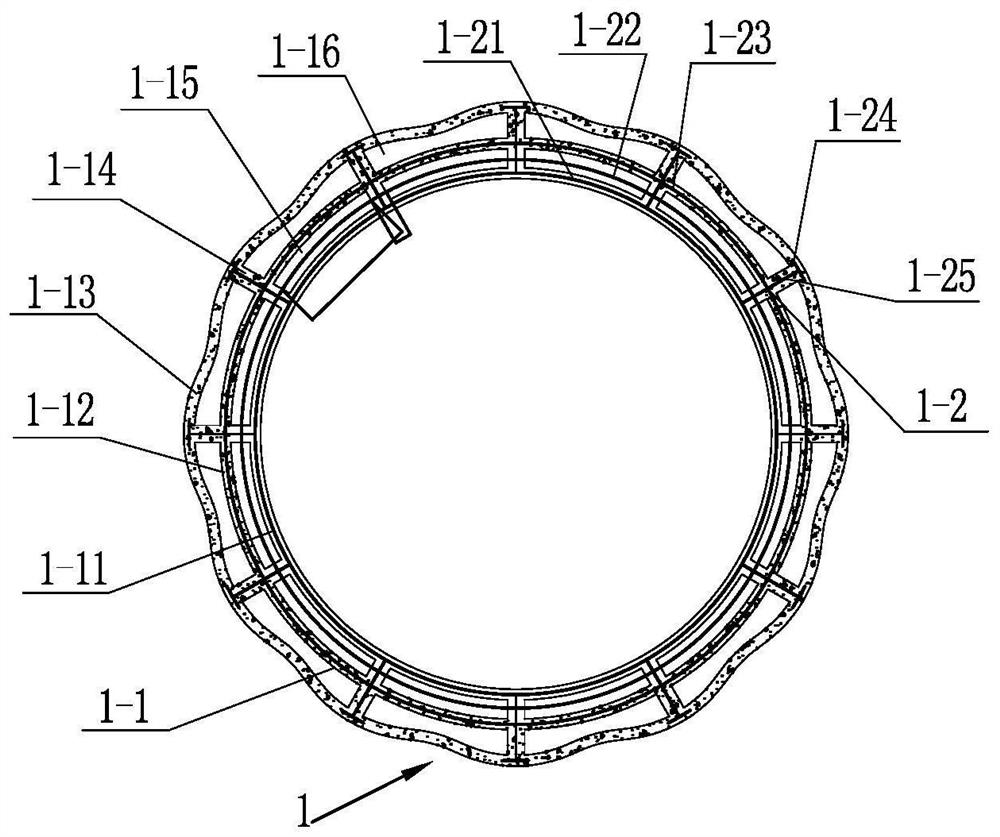

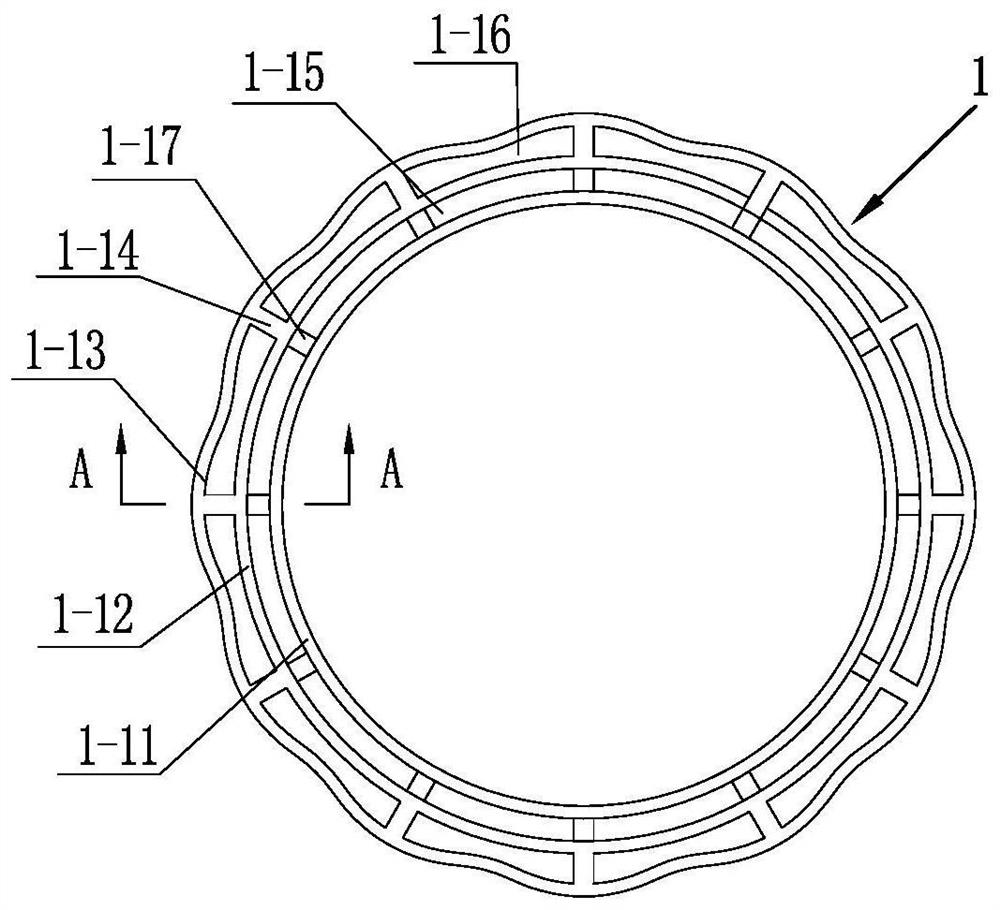

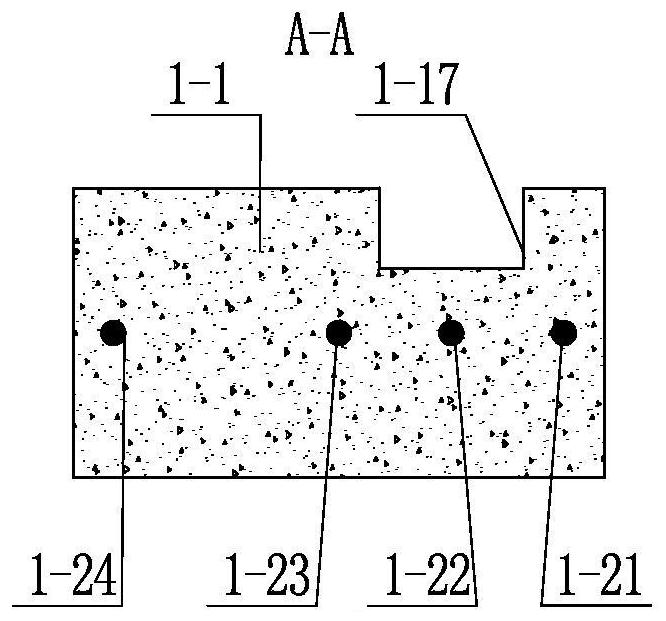

[0035] Make the first well body component 1, see Figure 1~3As shown, the first inner cover 1-11, the first outer cover 1-12 and the decorative ring 1-13 are printed from the inside to the outside with concrete 3D, and the first inner cover 1-11, the first outer cover 1-12 are connected The first well wall 1-1 composed of a plurality of first ribs 1-14 on the decorative ring 1-13, the first ribs 1-14 in pairs and the first inner sleeve 1-11 and the first outer sleeve 1-1 12 Form the first cavity for grouting and the overhead cavity 1-16 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com