Green building curtain wall structure

A green building and curtain wall technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of not being able to clean the curtain wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

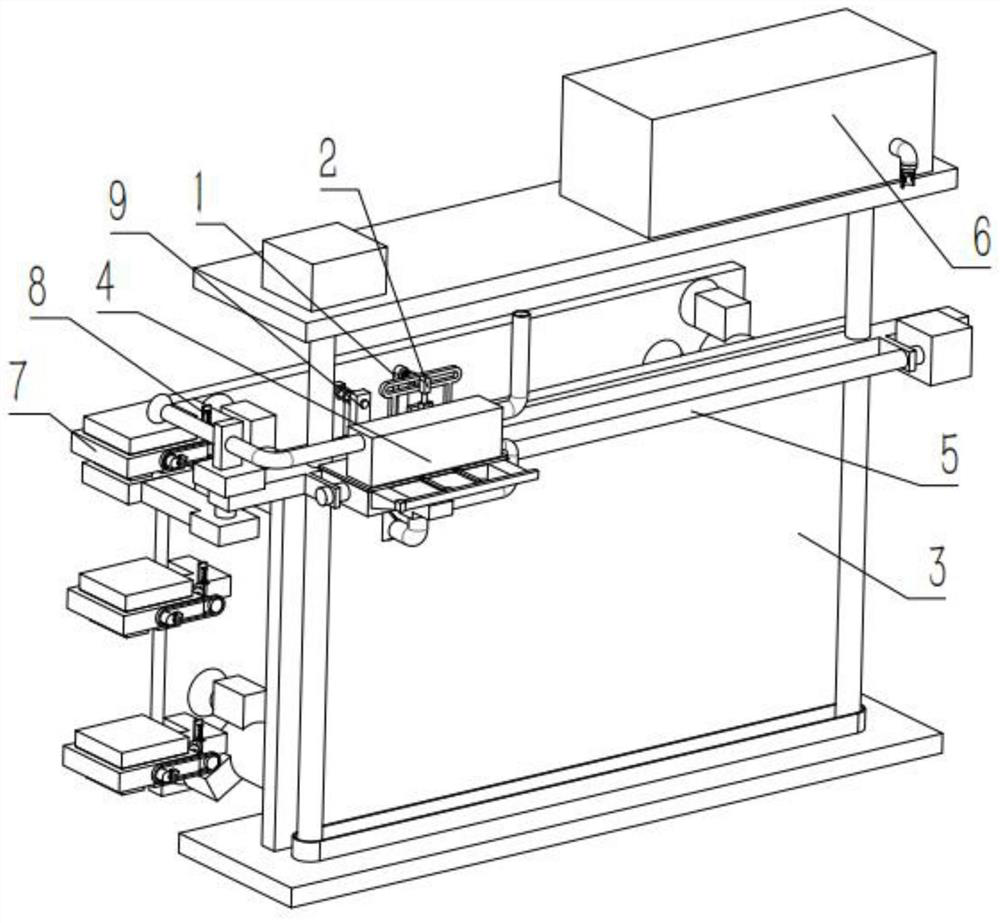

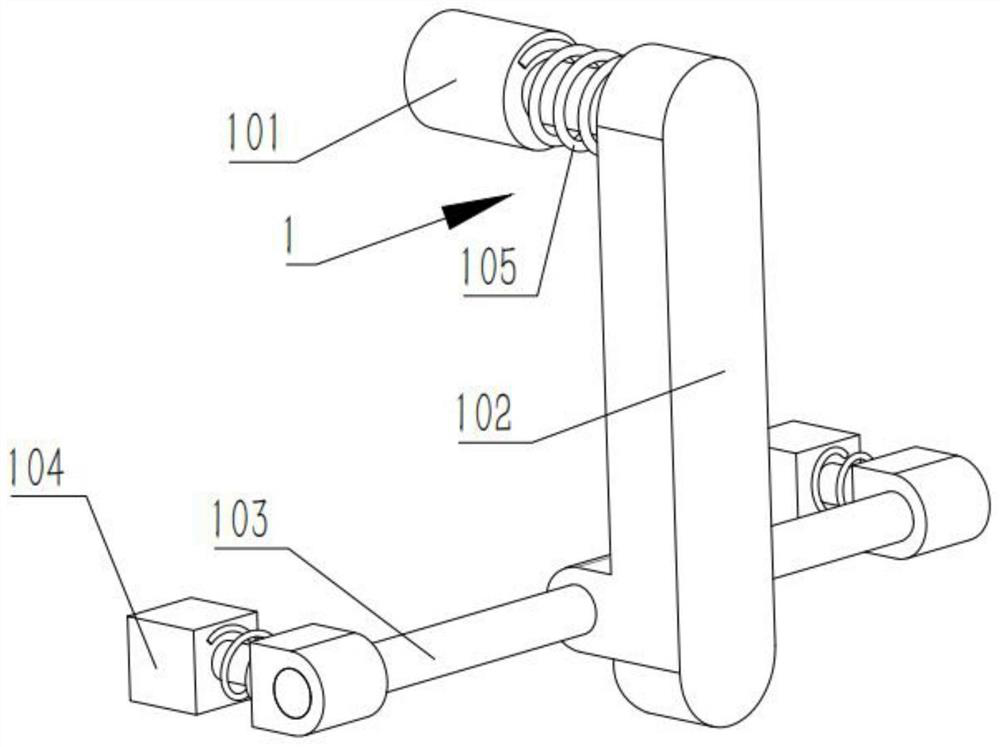

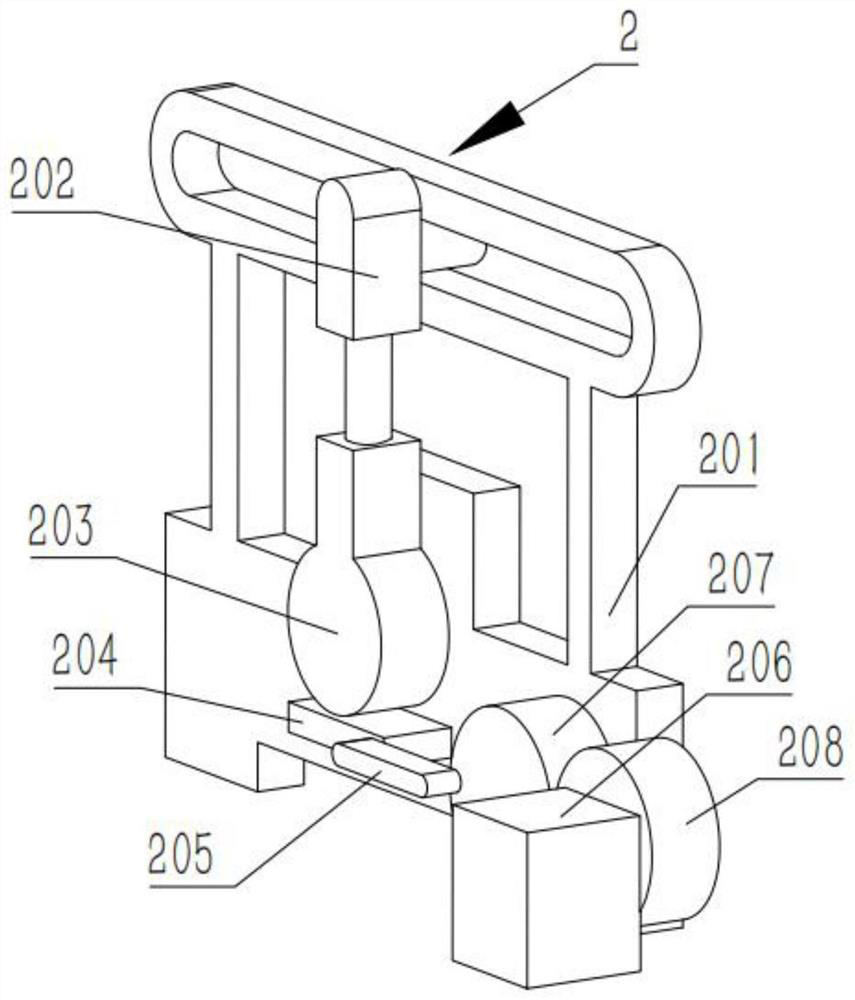

[0034] Combine below Figure 1-11Describe this embodiment, a green building curtain wall structure, including a scrubbing mechanism 1, a swing mechanism 2, a curtain wall mechanism 3 and a water spray mechanism 4, the scrubbing mechanism 1 includes a sliding sleeve 101, a scrubbing brush 102, a sliding rod 103, and a support seat 104 and support spring 105, scrubbing brush 102 is slidably connected on the sliding sleeve 101, and scrubbing brush 102 is slidably connected on the sliding rod 103, and sliding rod 103 is slidably connected on two supporting bases 104, is provided with three supporting springs 105, one of them The support spring 105 is fixedly connected between the sliding sleeve 101 and the scrubbing brush 102, and the other two support springs 105 are respectively fixedly connected between the slide bar 103 and the two support seats 104. The swing mechanism 2 includes a swing frame 201, a moving bar 202 and Turn the gear 203, the moving rod 202 is slidably connect...

specific Embodiment approach 2

[0037] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the swing mechanism 2 also includes a sliding rack 204, a rotating rod 205, a swing motor 206, an eccentric wheel 207 and a transmission gear 208, and the sliding rack 204 is slidably connected to On the swing frame 201, the sliding rack 204 and the rotating gear 203 are meshed for transmission, the rotating rod 205 is rotatably connected to the sliding rack 204, the rotating rod 205 is rotatably connected to the eccentric wheel 207, and the transmission gear 208 is fixedly connected to the output shaft of the swing motor 206 On, the eccentric wheel 207 and the transmission gear 208 are meshed for transmission, and the eccentric wheel 207 is rotatably connected to the swing frame 201;

[0038] The output shaft of the swing motor 206 rotates to drive the transmission gear 208 to rotate, the transmission gear 208 rotates to drive the eccentric wheel 207 to rotate, the e...

specific Embodiment approach 3

[0040] Combine below Figure 1-11 Describe this embodiment mode, this embodiment mode will further explain Embodiment 2. The curtain wall mechanism 3 also includes an inner wall 301, a connecting rod 303 and a suction cup 304, and a plurality of suction cups 304 are fixedly connected to a plurality of connecting rods 303. Each suction cup 304 is fixedly connected on the inner wall 301, and a plurality of connecting rods 303 are fixedly connected on the outer glass 302;

[0041] An inner wall 301 and an outer glass 302 are provided, which are connected by a connecting rod 303 and a suction cup 304, so as to facilitate replacement of damaged inner walls 301 and outer glass 302 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com