Surface cleaning device of copper-clad aluminum conductor through water-soluble drawing oil

A technology of surface cleaning device and copper-clad aluminum wire, applied in the direction of metal extrusion cleaning equipment, metal extrusion, manufacturing tools, etc., can solve the problems of affecting the working environment, affecting work efficiency, uneven winding, etc., and achieve improvement Cleaning efficiency, improved drying speed, and favorable drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

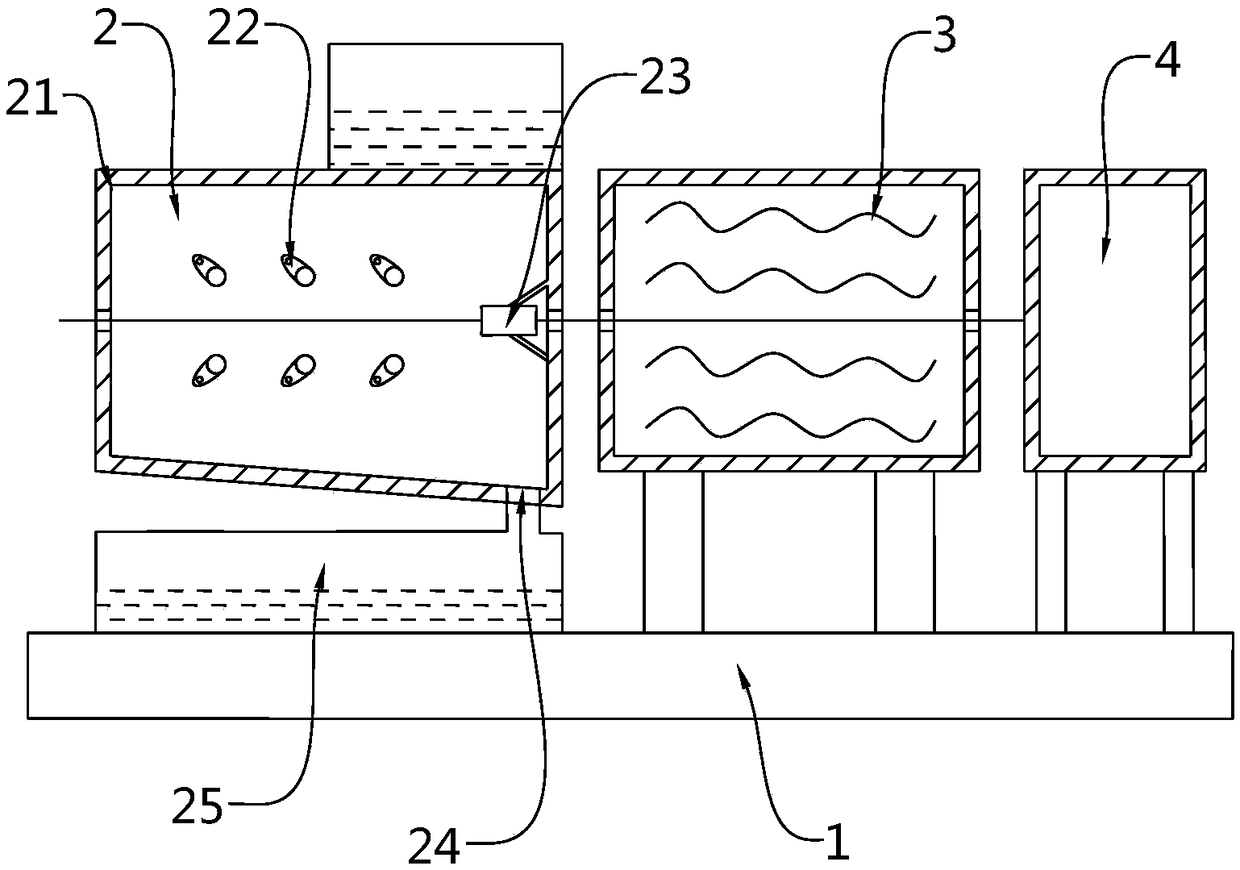

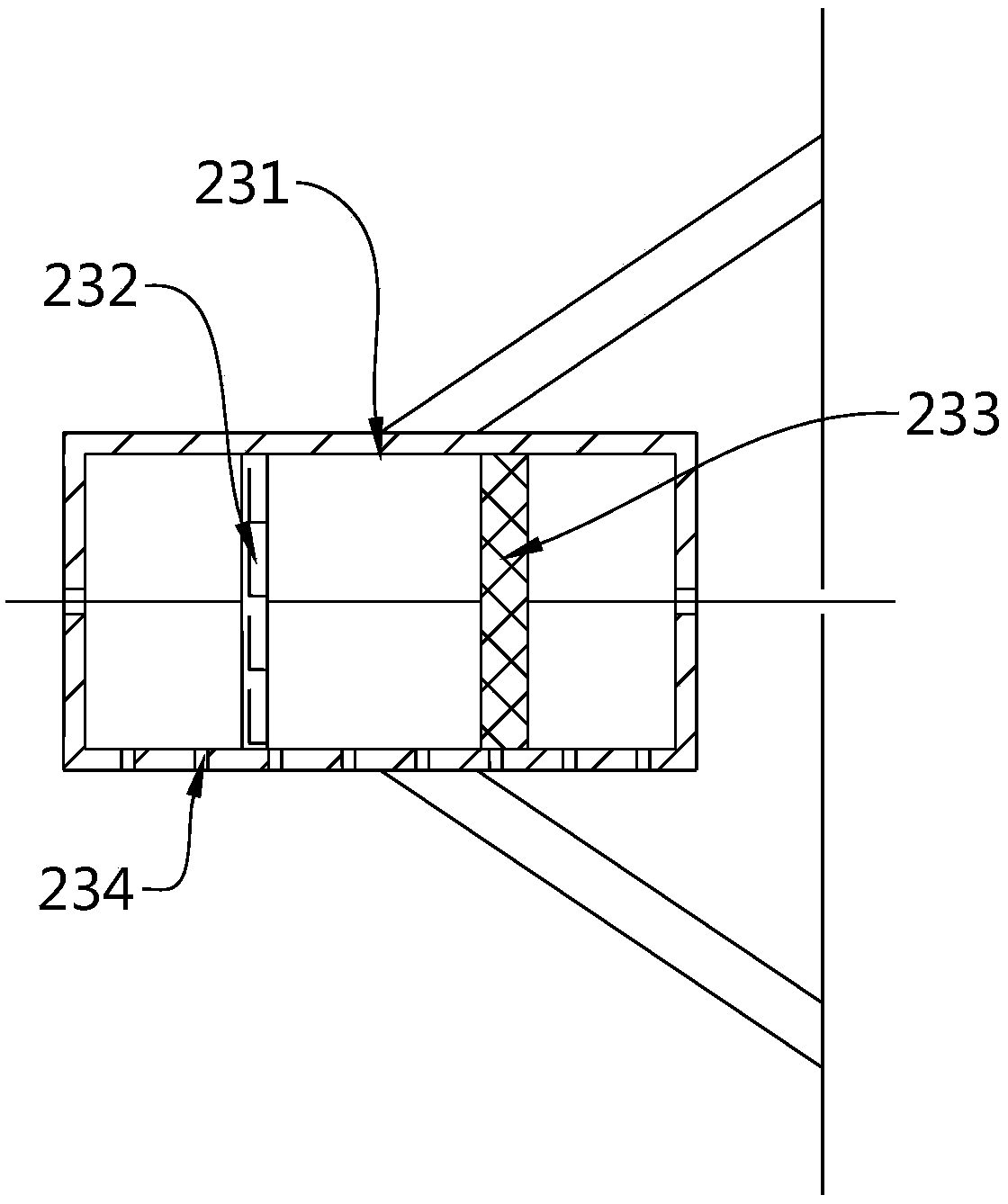

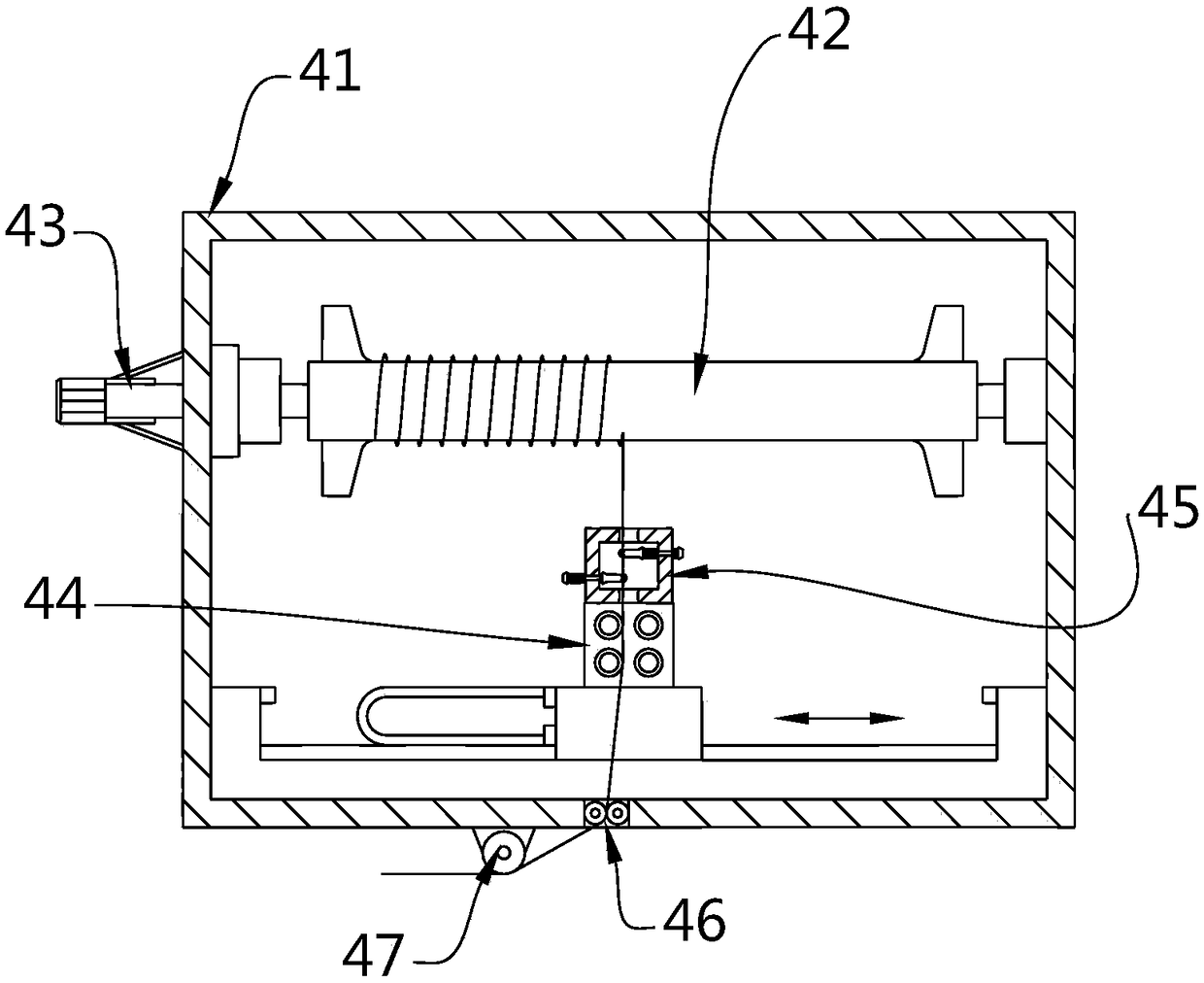

[0019] Embodiment: A kind of surface cleaning device of the copper-clad aluminum wire that adopts water-soluble drawing oil, structure such as Figure 1 to Figure 5 As shown, it includes a mounting bracket 1 on which a cleaning mechanism 2, a drying mechanism 3 and a winding mechanism 4 are sequentially arranged; the cleaning mechanism 2 includes a box body 21, and the two sides of the box body 21 are respectively provided with incoming outlet and outlet, the inner wall of the box body 21 is provided with several spraying mechanisms 22, the spraying mechanism 22 is connected with a water tank arranged outside the box body 21, and the inside of the box body 21 is provided with a wiping mechanism 23 on the side close to the outlet port, the box body The bottom of 21 is provided with a water outlet 24, and the box body 21 is connected to a waste water recovery pool 25 through an outlet pipe; the winding mechanism 4 includes a frame-shaped frame 41, and a winding roller 42 is horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com