Fabricated steel structure concrete building body

A concrete building and steel structure technology, applied in buildings, protected buildings/shelters, structural elements, etc., can solve problems such as insufficient bearing capacity, large consumption of concrete, and easy production of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

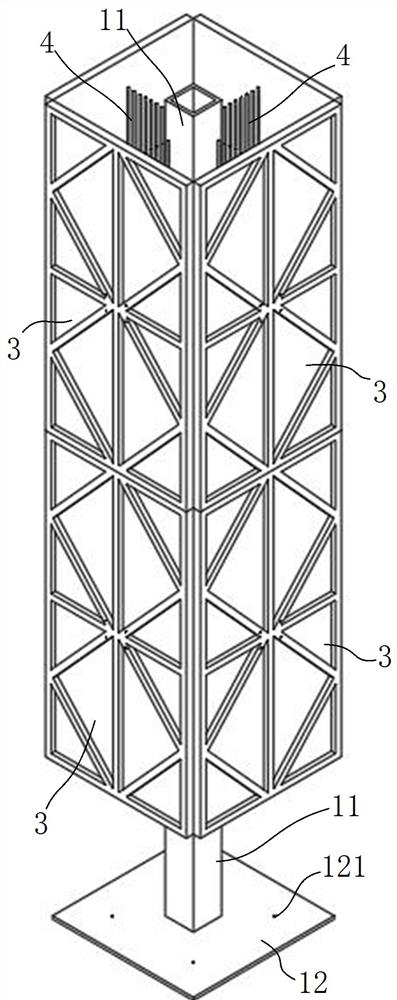

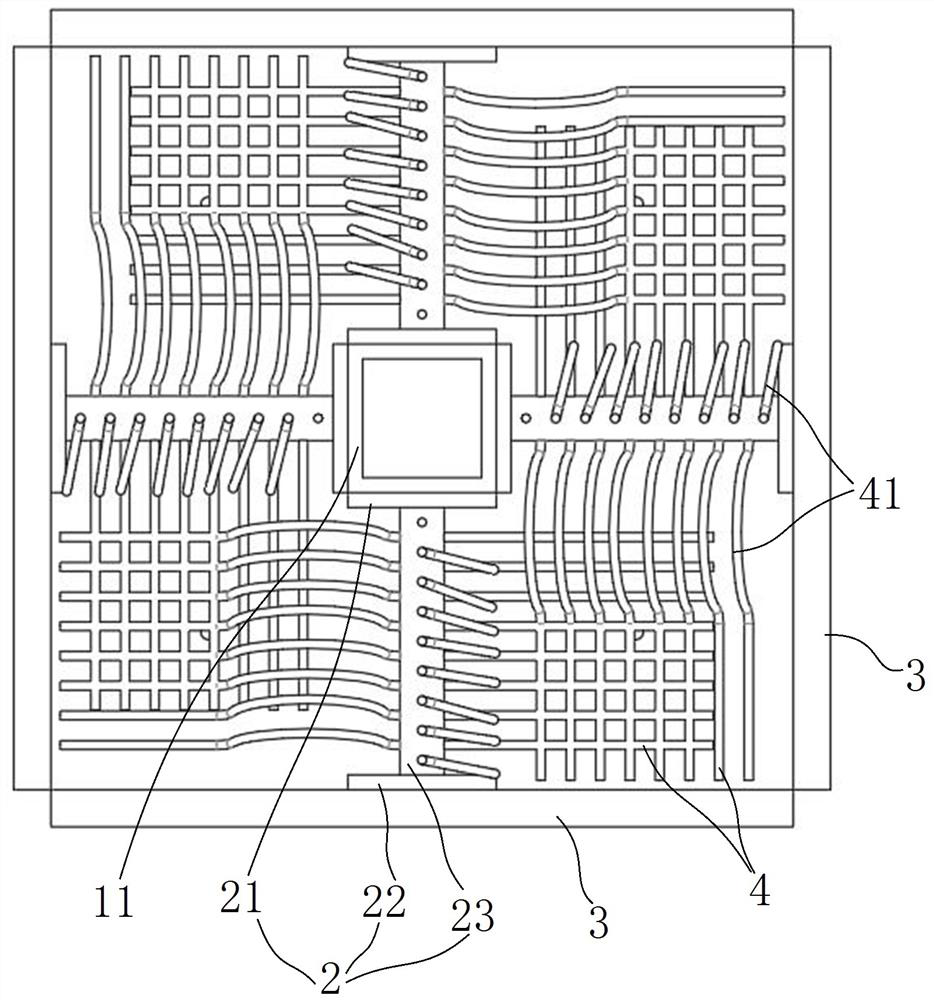

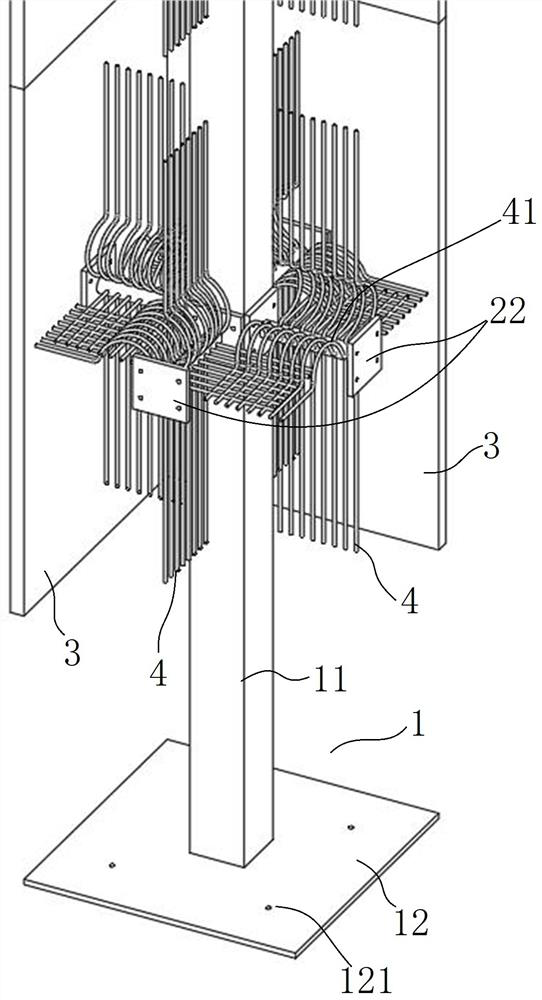

[0034] Such as Figure 1-3 As shown, the prefabricated steel structure concrete building includes bearing columns 1 , connecting rods 2 and rectangular formwork 3 . figure 1 Only the local structure is shown in .

[0035] Specifically, the prefabricated steel structure concrete building includes:

[0036] Such as Image 6 As shown, the load-bearing column 1, as the main load-bearing component, includes a central column 11 made of a square tube and a foot plate 12 fixed at least one end of the load-bearing column 1. The foot plate 12 is used to be embedded in the concrete foundation, and the inside of the central column 11 It has a cavity, and a plurality of threaded holes 111 are arranged at intervals on the surrounding surface of the central column 11, wherein the size of the central column 11 is 100mm*100mm, the steel pipe with a thickness of 10mm, a length of 4 meters, and 0.5 meters at both ends are pre-buried in the In the concrete of the lower part and the upper part; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com