Staggered dotting oil cooler pipe

An oil cooler and tube body technology, applied in the field of automobile radiator components, can solve the problems of weak pressure strength at the inlet and outlet ends of the oil cooling tube body, unable to achieve the oil cooling effect, low working pressure of the oil cooling tube body, etc. The effect of reducing the weight of the cooler, avoiding excessive impact, and not reducing the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

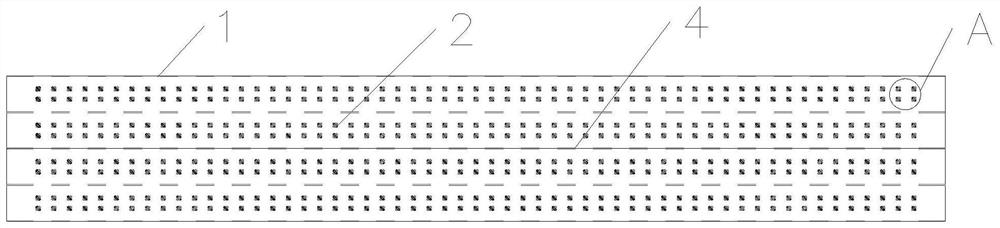

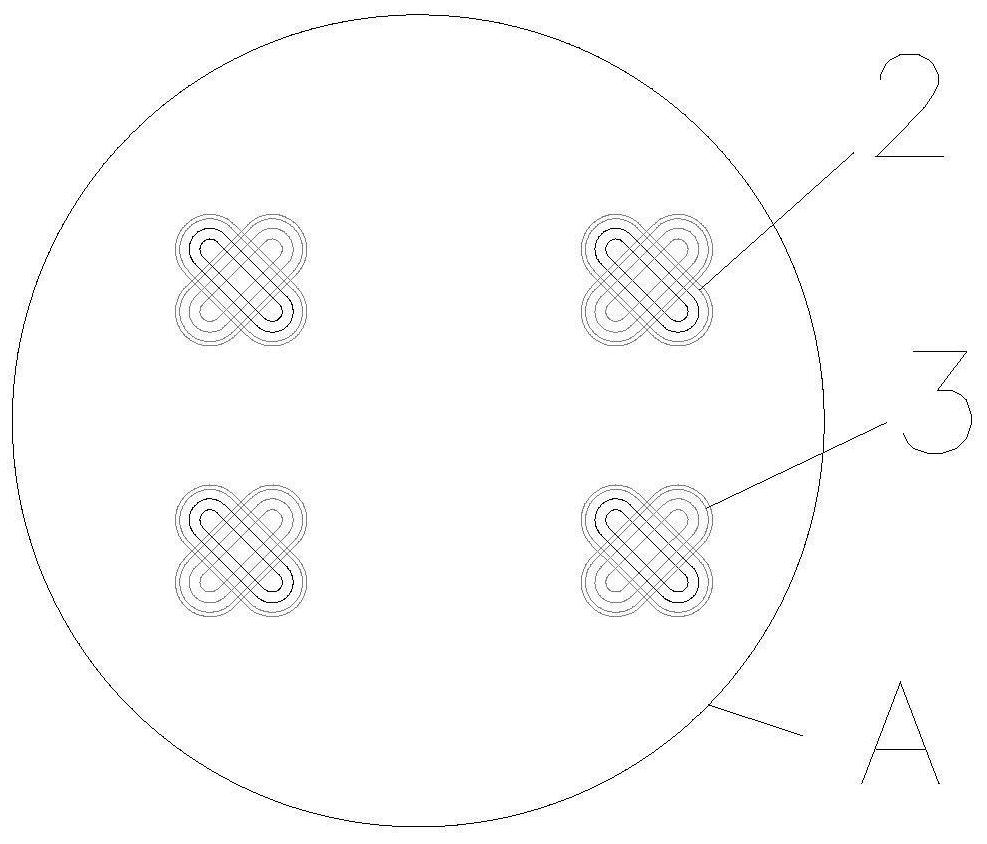

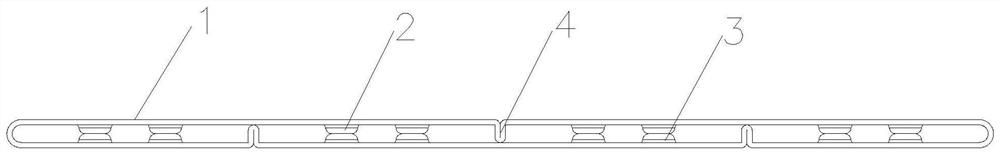

[0037] Such as Figure 1-3 As shown, the misplaced dotting oil cooler tube of the present invention includes a tube body 1, the thickness of the tube body 1 is 3.0mm, and the width is 10.0mm; A first groove 2 formed by the inward depression of the pipe wall, the lower surface of the pipe body 1 is provided with a plurality of second grooves 3 formed by the inward depression of the pipe wall; the bottom of the first groove 2 and the second groove 3 Bottom welded. The axial direction of the first groove 2 and the axial direction of the second groove 3 are perpendicular to each other, and the included angle between them and the axis of the tube body 1 is 45°.

[0038] The first groove 2 and the second groove 3 are all provided with 6 rows, every 2 rows of the first groove 2 are evenly distributed, the length of the first groove 2 is 1.5mm, and the maximum width is 0.4mm. The number, length and width of the grooves 3 are the same as those of the first groove 2 .

[0039] There ...

Embodiment 2

[0041] Such as Figure 4 As shown, the difference between the misplaced dotted oil cooler tube of this embodiment and the first embodiment is that the inner walls of both sides of the tube body 1 are provided with reinforcing pieces 5 .

Embodiment 3

[0043] Such as Figure 5-6 As shown, the difference between the misplaced dotted oil cooler tube of this embodiment and that of Embodiment 1 is that the tube body 1 is bent from a piece of sheet body, and a first bending portion 6 is provided at the bend of the sheet body. The two free ends of the sheet are respectively provided with a second bending portion 7 and a third bending portion 8 . The first bending part 6 is formed by folding three layers of a sheet body, and the second bending part 7 and the third bending part 8 are formed by folding three layers of two free ends of the sheet body into the tube body 1 , and the heights of the second bending portion 7 and the third bending portion 8 are half of the height of the first bending portion 6, the first bending portion 6, the second bending portion 7, and the third bending portion 8 The thickness is the same after folding. The second bending portion 7 and the third bending portion 8 are closed by high frequency welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com