Rotor structure of large-shaft-diameter built-in permanent magnet motor and motor thereof

A permanent magnet motor and rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of increasing the radial thickness of the rotor, etc., to achieve Effects of reducing erosion, increasing sine degree, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

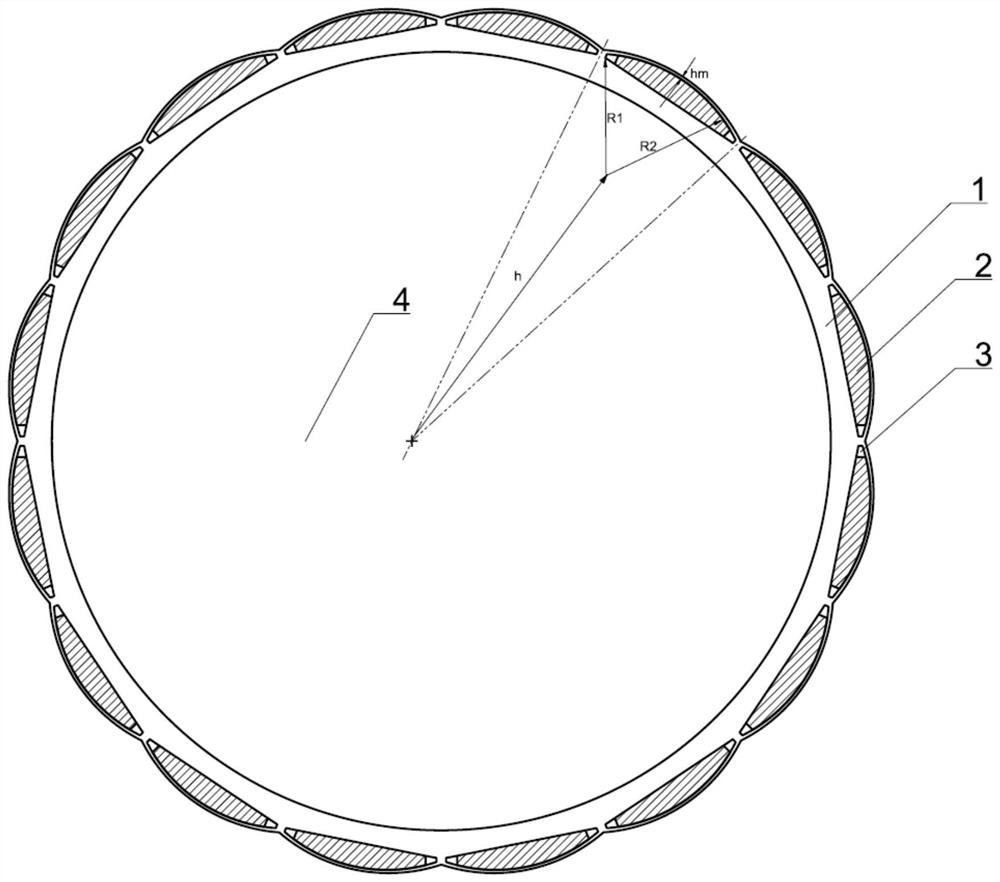

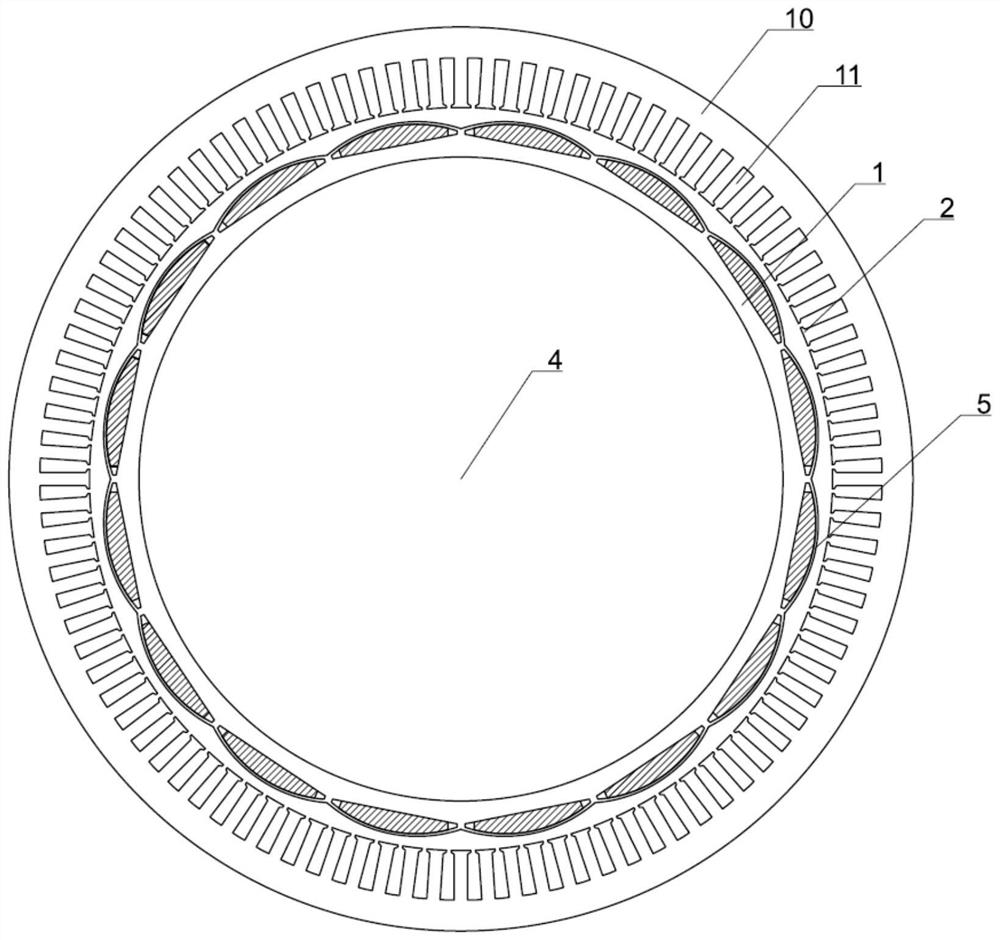

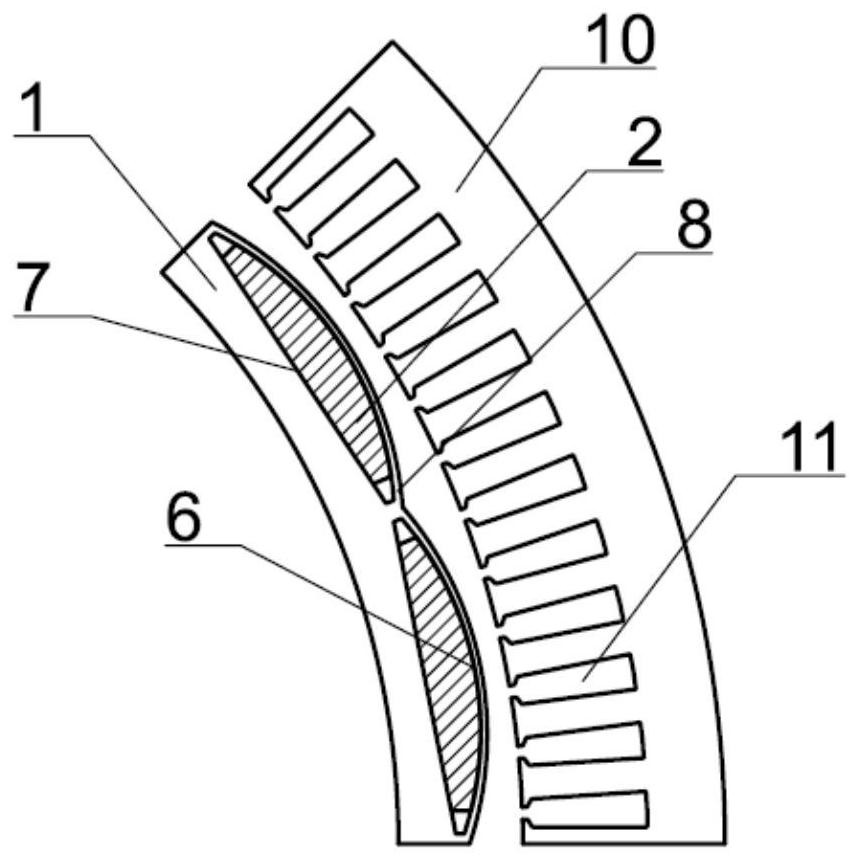

[0032] Such as figure 1 , 4 As shown, the rotor structure of the large shaft diameter built-in permanent magnet motor includes a rotor core 1; 16 (p=8) semi-shuttle-shaped magnetic steel grooves 3 are evenly distributed inside the rotor core 1 along the circumferential direction, and the magnetic steel grooves are circular. The arc surface 6 is a semi-shuttle-shaped arc edge, and the semi-shuttle-shaped arc edge takes the point near the arc direction and the center of the rotor core 1 as h as the center of the circle, and the length R 1 Be radius, magnetic steel groove bottom surface 7 is the straight edge of half shuttle.

[0033] The inside of the magnetic steel slot 3 is fixed with a semi-shuttle permanent magnet 2, and the arc surface of the semi-shuttle permanent magnet 2 is at the same position as the center of the arc surface 6 of the magnetic steel slot and has the same radius; The eccentric arc parallel to the groove arc surface 6, the eccentric arc is concentric wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com