Stator assembly and motor using same

A component and stator technology, applied in the direction of electric components, winding insulation shape/style/structure, winding, etc., to avoid adverse situations and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

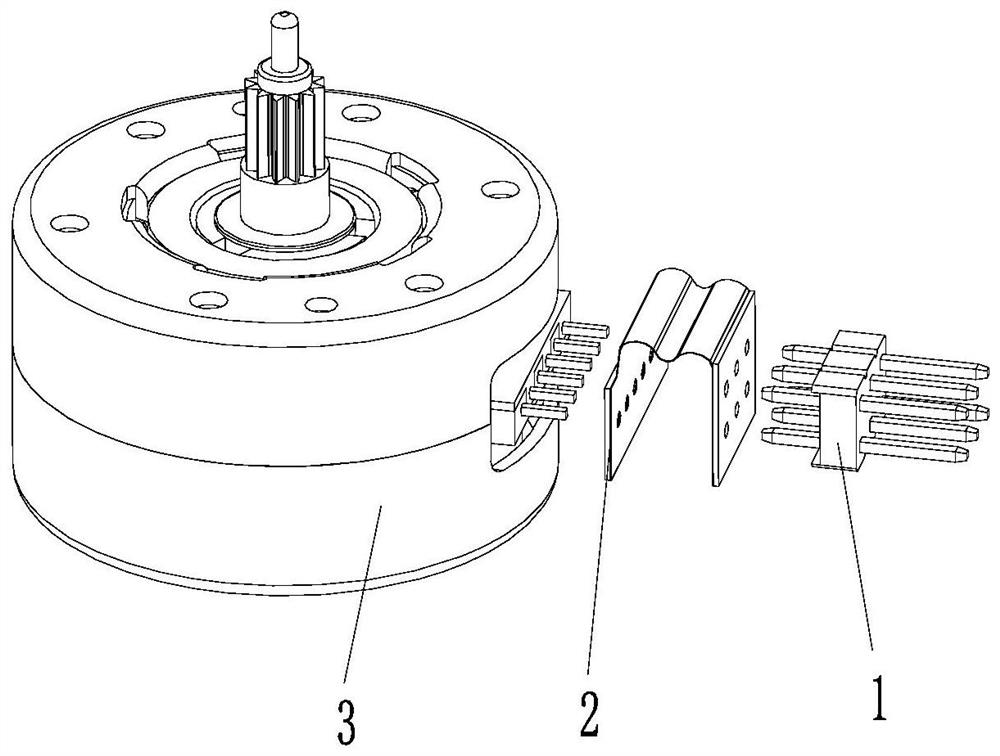

[0087] refer to Figure 4 to Figure 23 , the present embodiment provides a stator assembly, including: an outer casing 7 serving as a stator core, an insulating frame, a winding 8 and a terminal post 10 . Wherein the insulating skeleton includes a skeleton main body 11 and a skeleton protruding part, where the skeleton protruding part is arranged on the circumferential edge of one axial end of the skeleton main body 11 and extends toward the radial direction of the skeleton main body 11; the winding 8 is suitable for Wound on the main body 11 of the skeleton, the terminal post 10 is adapted to be fixedly held on the protruding part of the skeleton.

[0088] In detail, the skeleton protruding portion includes a stud holder 12 for fixing and holding the stud 10, and a coupling portion located between the stud holder 12 and the skeleton body 11 to connect the stud holder 12 and the skeleton body 11 13; For this embodiment, the coupling portion 13 extends along one of the tangent...

Embodiment 2

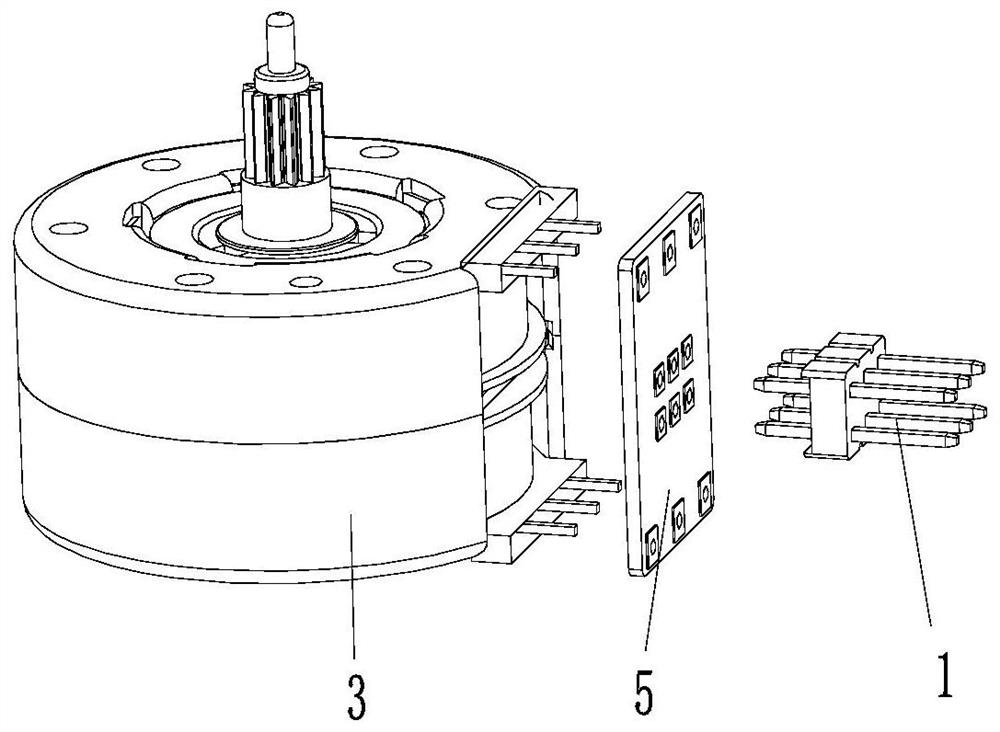

[0106] refer to Figure 24 Figure 32 , on the basis of Embodiment 1, the stator assembly provided by this embodiment has substantially the same structure as the stator assembly of Embodiment 1. Specifically, the stator assembly of this embodiment includes: an outer shell 7 serving as a stator core, an insulating frame, a winding 8 and a terminal post 10 . The insulating skeleton includes a skeleton main body 11 and a skeleton protruding part, where the skeleton protruding part is arranged on the circumferential edge of one axial end of the skeleton main body 11 and extends toward the radial direction of the skeleton main body 11, defined in this embodiment The extension direction of the protruding part of the skeleton is the Y axis; the winding 8 is suitable for winding on the main body 11 of the skeleton, and the terminal post 10 is suitable for being fixed and held on the protruding part of the skeleton.

[0107] In detail, the skeleton protruding portion includes a stud ...

Embodiment 3

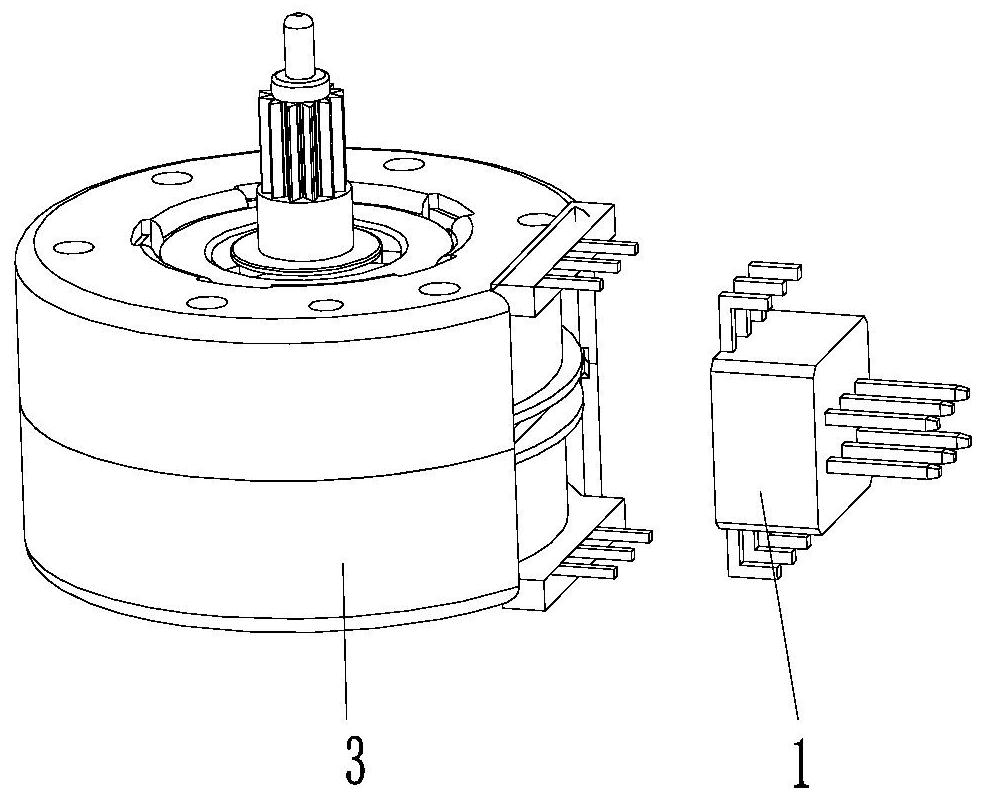

[0118] On the basis of the stator assembly of embodiment 1 or embodiment 2, the motor provided in this embodiment includes the stator assembly of embodiment 1 or embodiment 2 and the rotor structure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com