Integrated atomizing core with protective cover

A technology of protective cover and atomizing core, which is applied in the direction of therapeutic atomizers, tobacco, etc., can solve the problems of difficult automatic production, fragmentation, and reduce the effect of atomization, so as to realize automatic production, improve service life and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

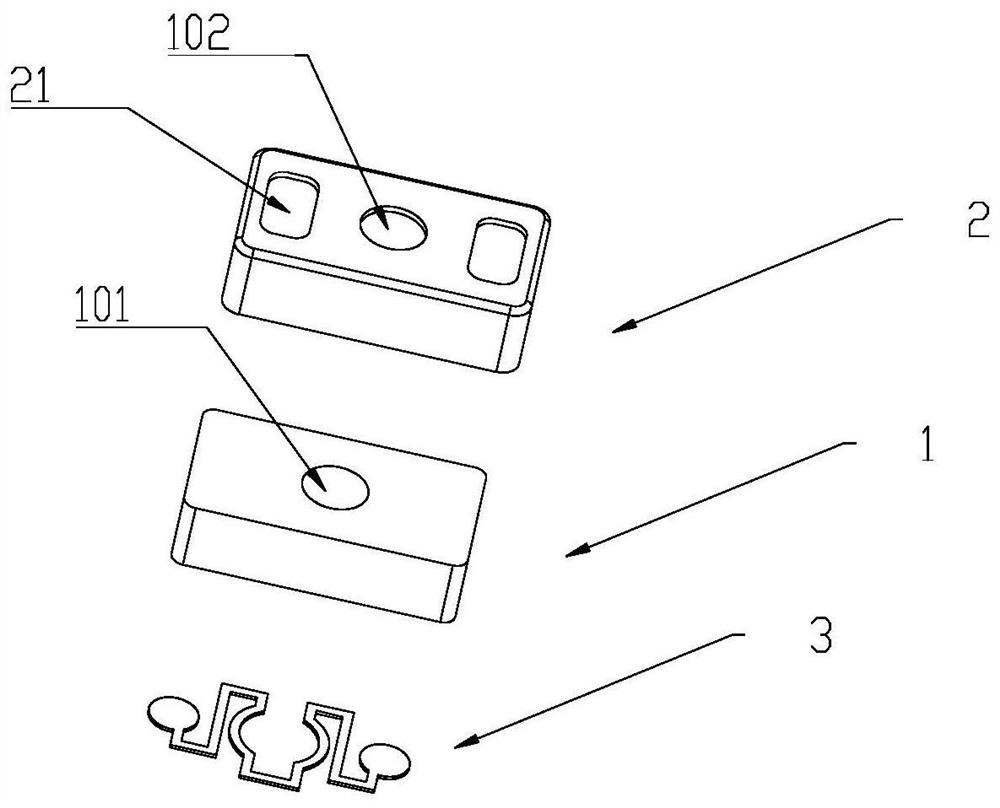

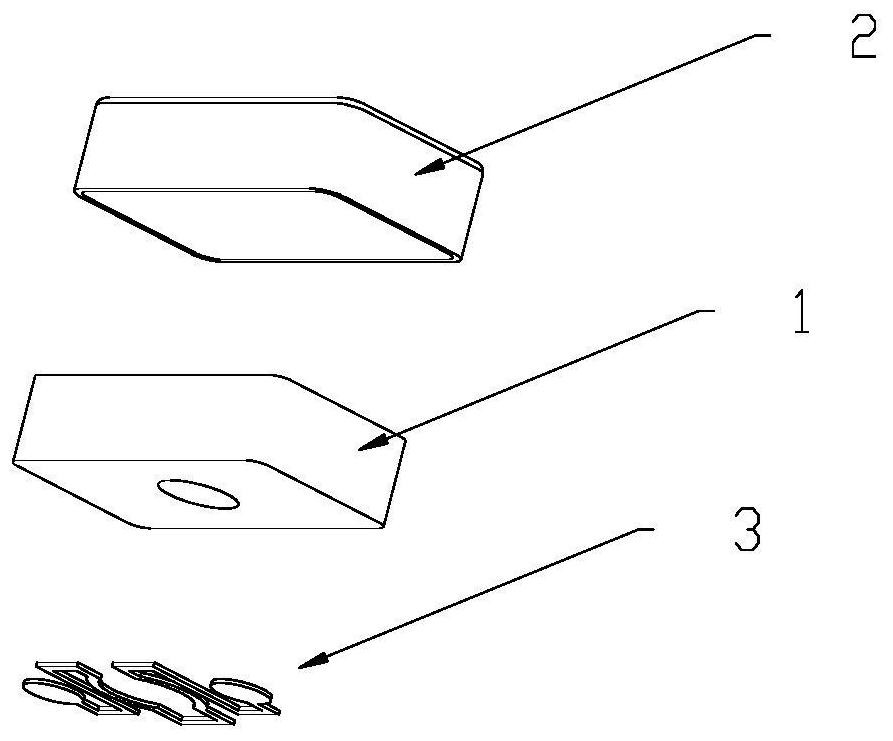

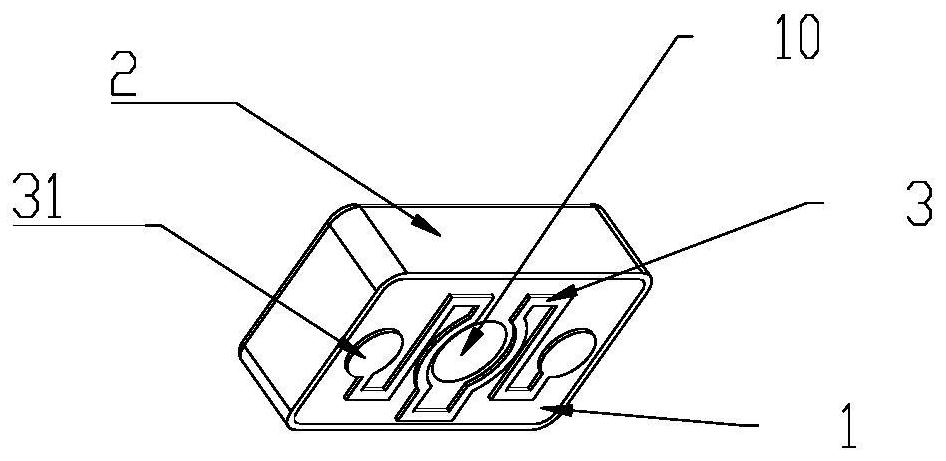

[0028] Such as Figure 1-Figure 7 As shown, the atomizing core of this embodiment includes a flat conductive liquid 1 for absorbing and conducting the liquid to be atomized. The side of the conductive liquid 1 is closely attached to a protective cover 2, and the conductive liquid 1 and the protective cover 2 are combined. A vertical and continuous mist outlet hole 10 is provided, that is, a vertical first mist outlet hole 101 is provided in the guide liquid 1, and the position corresponding to the first mist outlet hole 101 is provided with the same and Through the second mist outlet hole 102 , an orifice 21 is provided on the protective cover 2 , and the orifice 21 is used to introduce the liquid to be atomized into the guide liquid 1 . The lower surface of the conductive liquid 1 is provided with a heating element 3. After the heating element 3 is energized, it can heat the liquid to be atomized in the conductive liquid 1, and the atomized liquid evaporates from the lower su...

Embodiment 2

[0035] This embodiment has some different features on the basis of Embodiment 1, specifically including:

[0036] Such as Figure 8 , Figure 9 As shown, the upper surface of the guide liquid 1 is located at the position of the orifice 21 and is provided with a guide groove 11 downward. The liquid guide groove 11 is used to accommodate and temporarily store the liquid to be atomized flowing out of the liquid storage chamber in the nebulizer.

[0037] The heating element 3 is arranged in the part of the conductive liquid 1 close to the lower surface (not shown in the figure)

[0038] Refer to Embodiment 1 for other parts not mentioned in this embodiment.

Embodiment 3

[0040] This embodiment has some different features on the basis of Embodiment 1, specifically including:

[0041] Such as Figure 10 As shown, the outer side of the protective cover 2 is provided with a vertical mist outlet groove 20 for replacing the mist outlet through hole 10, and the mist outlet groove 20 and the inner wall of the atomization seat of the atomizer are enclosed to form a mist outlet channel.

[0042] Refer to Embodiment 1 for other parts not mentioned in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com