Industrial furnace with high-temperature low-oxygen air burner

An air combustion, high temperature and low oxygen technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of large smoke exhaust loss, high emission, not using energy saving and environmental protection requirements, etc., to achieve high energy utilization rate, The effect of small smoke exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

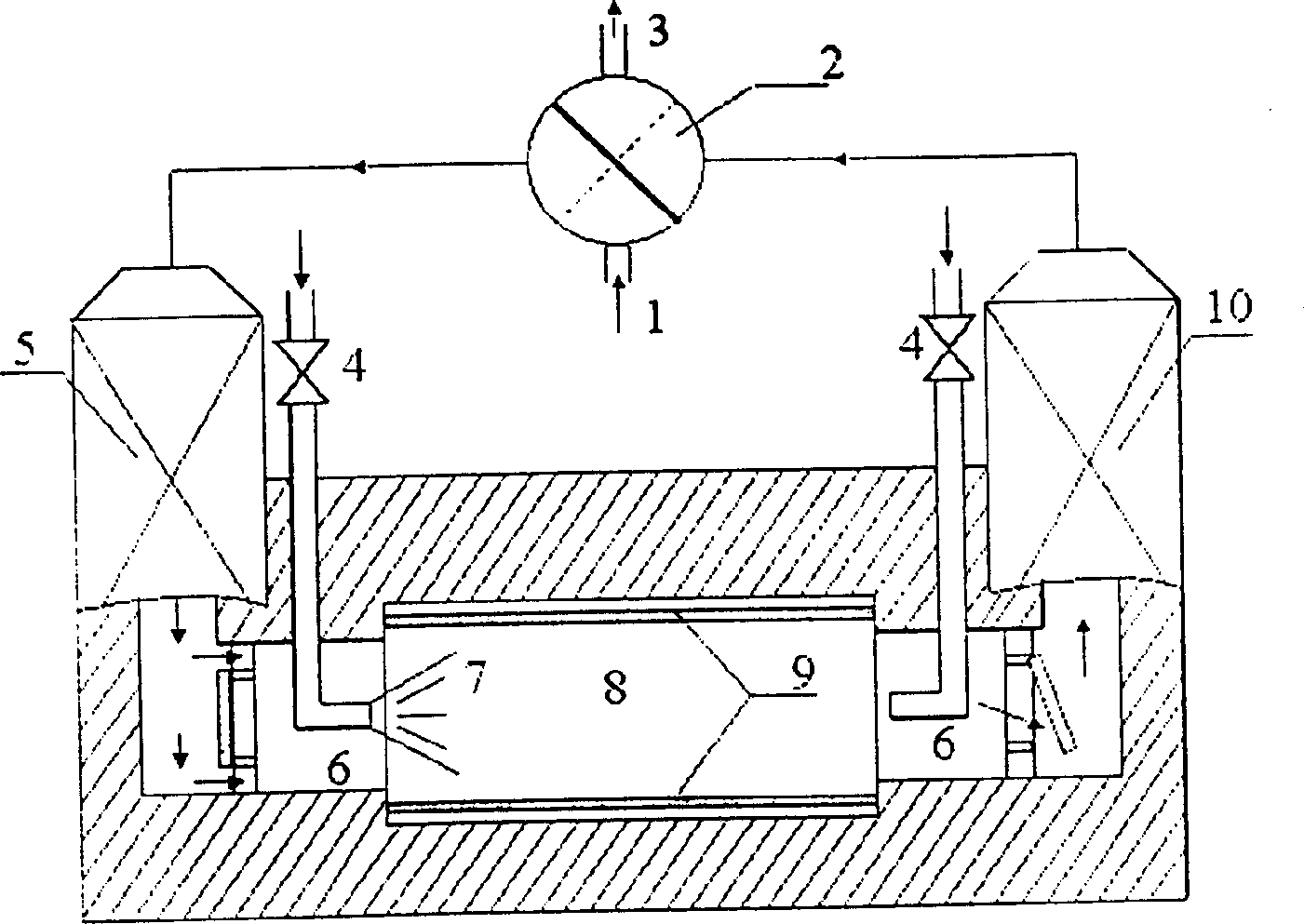

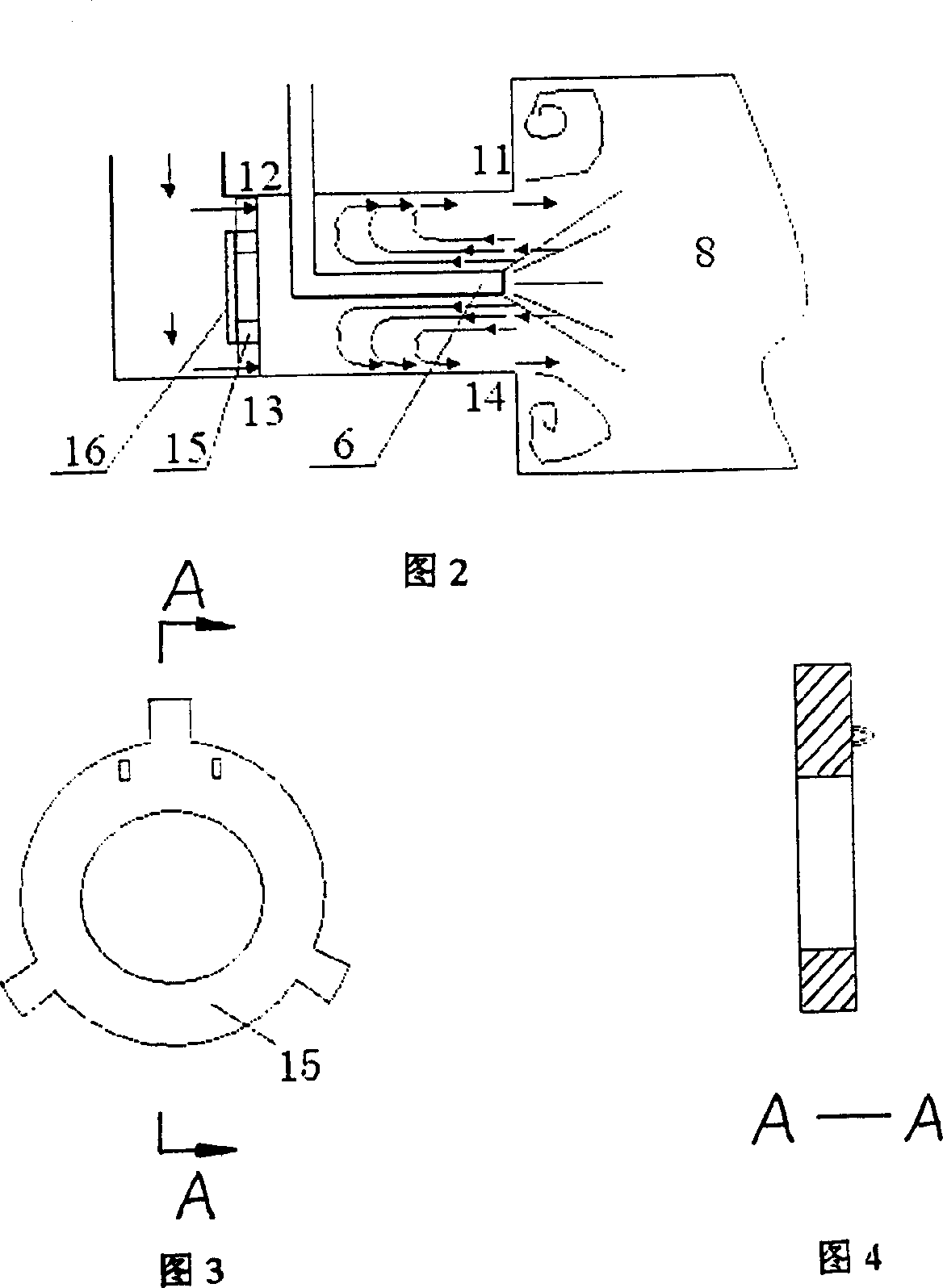

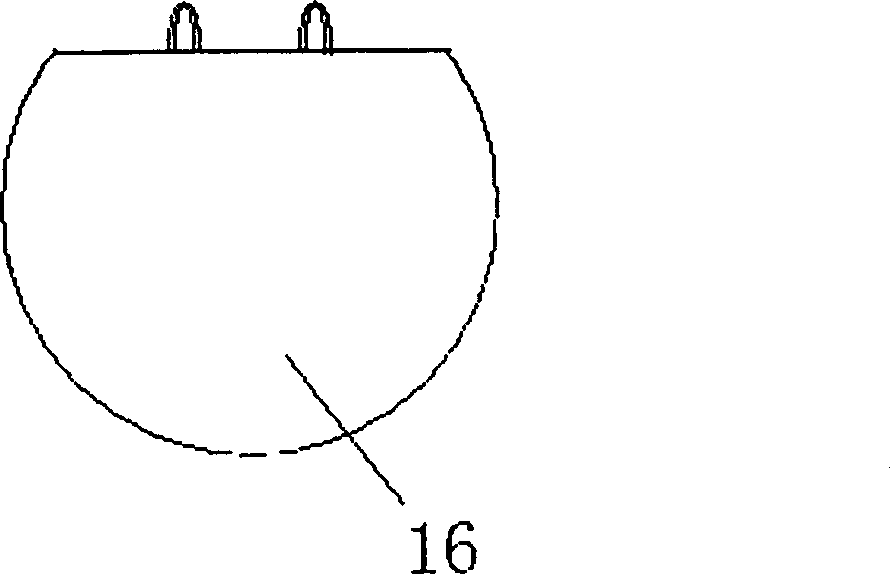

[0014] Below in conjunction with accompanying drawing, describe in detail the concrete structure of the present invention, working principle, working process and implementation mode: figure 1 It is a structural schematic diagram of an industrial furnace with a high-temperature low-oxygen air burner. It is mainly composed of a furnace 8, a fuel spray gun 6 respectively arranged on the left and right sides of the furnace, a solenoid valve 4, animal heat exchangers 5 and 10, and a blower 1. Composed of induced draft fan 3 and four-way reversing valve 2. A high-temperature low-oxygen air burner is respectively arranged at the left and right ends of the furnace 8, and the burner (Fig. Composed of 16. The end cover of the combustion chamber and the wall surface of the combustion chamber form an annular air intake passage. Fig. 3 is a kind of embodiment of the present invention, is provided with 3~5 supporting claws on the end cover 15, can form an annular air inlet channel, has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com