Sieve plate hole size adjustable mechanism

A technology of sieve plate holes and sieve plates, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of low work efficiency, laborious work, and inability to adjust sieve holes, and achieves reasonable structural design, simple principle, and easy promotion The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

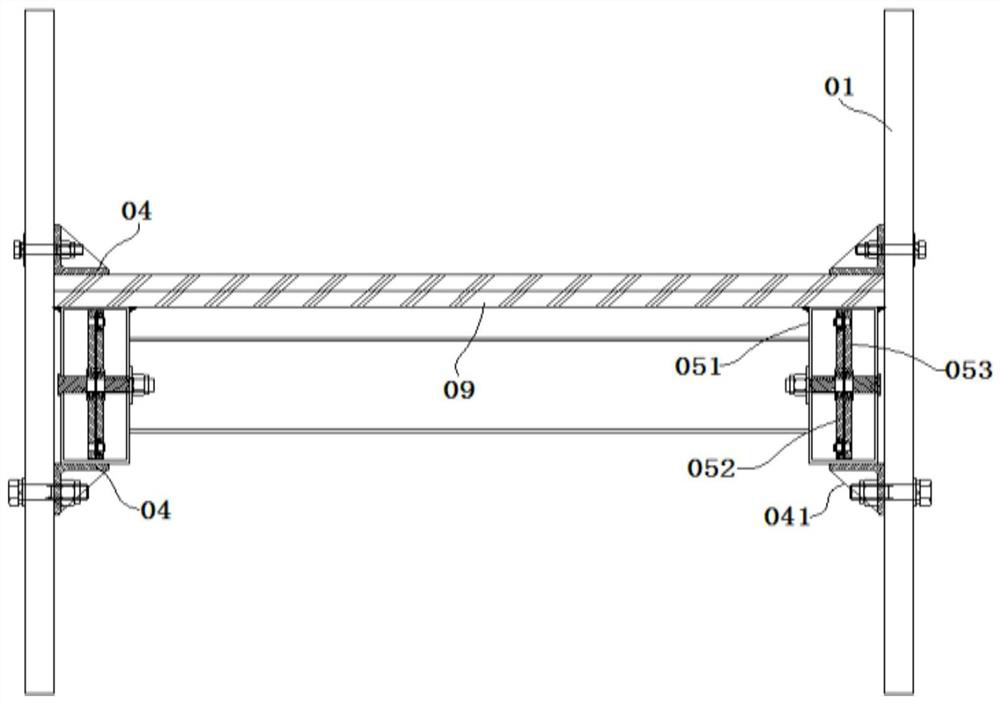

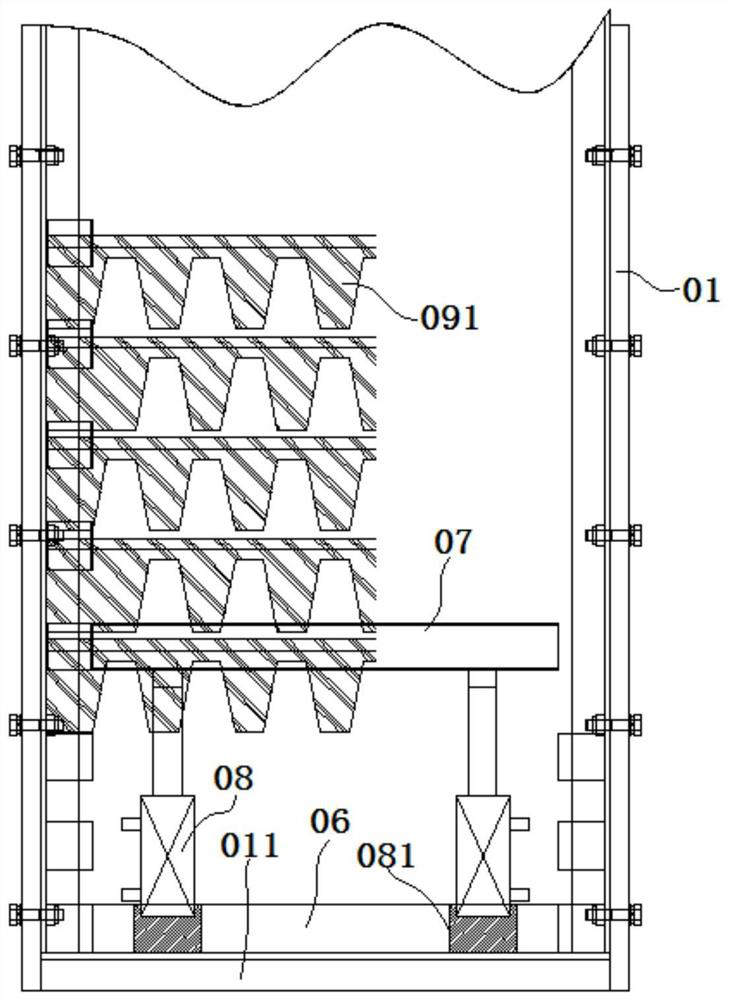

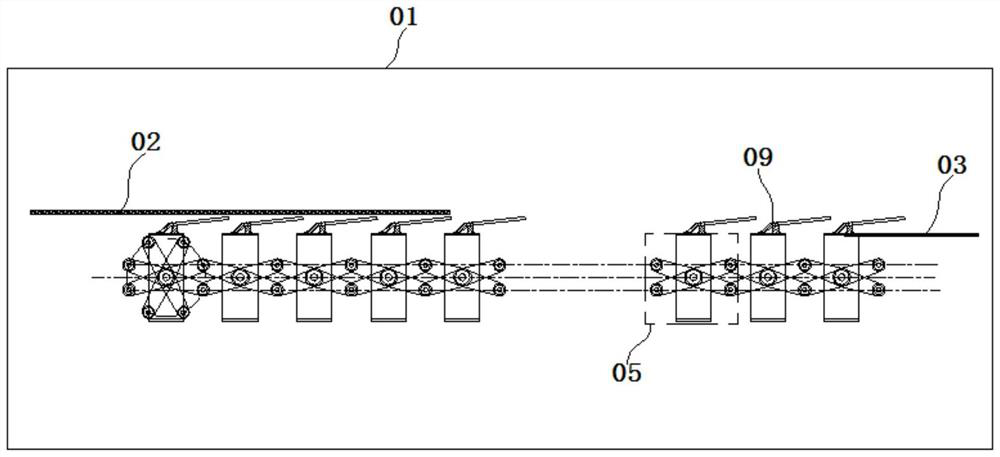

[0029] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a sieve plate hole size adjustable mechanism in this embodiment, including a sieve plate slider assembly and two side plates 01, the two side plates 01 are perpendicular to the ground and are facing each other, the inner surface of each side plate 01 Two fixed plates 04 are fixedly connected to each side plate 01, and the two fixed plates 04 on each side plate 01 are arranged up and down to form a sliding channel. Under the action of the drive assembly, it can slide and expand along the sliding channel to adjust the size of the sieve plate hole. Specifically in this embodiment: a beam 011 is connected between the tops of the two side panels 01 .

[0030] The sieve plate slider assembly includes multiple pairs of slider assemblies 05 arranged at equal intervals, wherein two slider assemblies 05 in a pair of slider assemblies 05 are symmetrically fixed in the corresponding sliding channels, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com