Hot-rolled thin-specification anti-seismic refractory steel plate with yield strength of 460 MPa and preparation method

A technology with yield strength and thin gauge, applied in the field of thin gauge anti-seismic fire-resistant steel plate with yield strength of 460MPa and its preparation, can solve the problems of difficulty in guaranteeing high-temperature performance, high cost of Mo element, and difficulty in producing thin-gauge anti-seismic fire-resistant steel. Reduce the difficulty of manufacturing, improve the performance pass rate, and the effect of good room temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

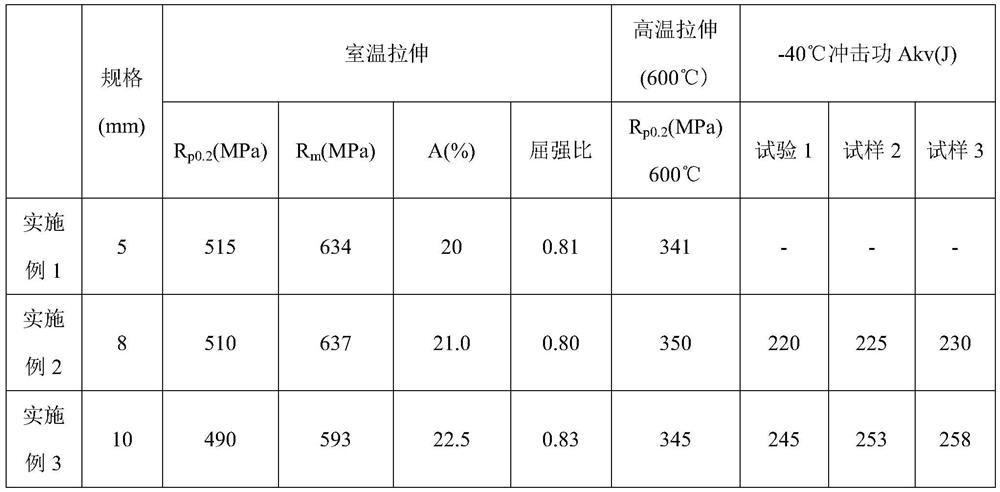

Examples

Embodiment 1

[0016] A method for manufacturing a hot-rolled thin-spec seismic refractory steel with a yield strength of 460 MPa with a thickness of 5 mm, comprising the following process steps:

[0017] (1) After the converter smelting process, the refining process outside the furnace, and the continuous casting process of molten steel pouring, the slabs with a thickness of 220mm and a length of 4000mm are casted respectively. The chemical composition of the slabs is: C: 0.04%, Si: 0.24%, Mn: 0.90%, P: 0.010%, S: 0.009%, Cr: 048%, Mo: 0.18%, Nb: 0.090%, V: 0.030%, Ti: 0.015%, Al: 0.03%, N: 0.0040%, The rest are Fe and inevitable impurity elements.

[0018] (2) The slab is heated in a heating furnace to obtain the original billet: the heating temperature is 1170 ° C, and the furnace time is 220 minutes, and a fine and uniform original austenite structure is obtained inside the steel;

[0019] (3) Roll the original billet into an intermediate billet with a thickness of 110mm and cool it nat...

Embodiment 2

[0023] A method for manufacturing a hot-rolled thin-spec seismic refractory steel with a yield strength of 460 MPa with a thickness of 8 mm, comprising the following process steps:

[0024] (1) Through the converter smelting process, the refining process outside the furnace, and the continuous casting billet process of molten steel pouring into a billet with a thickness of 220mm and a length of 4000mm, the chemical composition of the billet is: C: 0.05%, Si: 0.25%, Mn : 0.850%, P: 0.009%, S: 0.008%, Cr: 0.60%, Mo: 0.20%, Nb: 0.08%, V: 0.03%, Ti: 0.019%, Al: 0.032%, N: 0.0040%, the rest Fe and inevitable impurity elements

[0025] (2) The slab is heated in a heating furnace to obtain the original billet: the heating temperature is 1180 ° C, and the furnace time is 220 minutes, and a fine and uniform original austenite structure is obtained inside the steel;

[0026] (3) Roll the original billet into an intermediate billet with a thickness of 120mm and cool it naturally, and th...

Embodiment 3

[0030] A method for manufacturing a hot-rolled thin-spec seismic refractory steel with a yield strength of 460 MPa with a thickness of 10 mm, comprising the following process steps:

[0031] (1) Through the converter smelting process, the refining process outside the furnace, and the continuous casting billet process of molten steel pouring into a billet with a thickness of 220mm and a length of 4000mm, the chemical composition of the billet is: C: 0.06%, Si: 0.21%, Mn : 0.91%, P: 0.008%, S: 0.008%, Cr: 0.50%, Mo: 0.018%, Nb: 0.09%, V: 0.04%, Ti: 0.01809%, Al: 0.03%, N: 0.0050%, the rest Fe and inevitable impurity elements

[0032] (2) The slab is heated in a heating furnace to obtain the original billet: the heating temperature is 1216 ° C, and the furnace time is 220 minutes, and a fine and uniform original austenite structure is obtained inside the steel;

[0033] (3) The billet rolling process of the medium and heavy plate rolling mill: the original billet is rolled into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com