Forming jig for chip frame pin

A jig and frame technology, which is applied in the field of forming jigs for chip frame pins, and can solve problems such as metal tin peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

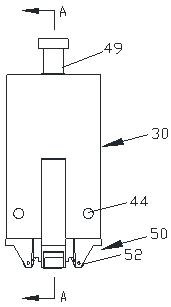

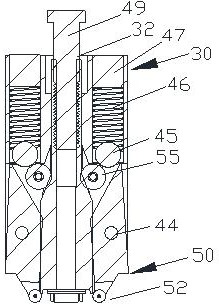

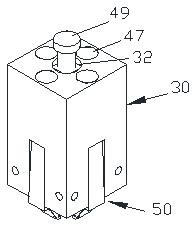

[0077] A molding tool for chip frame pins of the present invention, such as figure 1Shown is a schematic diagram of the structure of its forming fixture. The forming jig includes a stamping body part 30 , a thin pin 44 , a main shaft 60 , a bolt 49 , a forming support 50 and a forming base 10 , and the forming base 10 is arranged directly below the main shaft 60 . Such as Figure 2 to Figure 5 as shown, figure 2 for figure 1 The schematic diagram of the A-A section structure; image 3 and Figure 4 for figure 1 The schematic diagram of the three-dimensional structure; Figure 5 for figure 1 exploded diagram.

[0078] Such as Figure 6 As shown, it is a three-dimensional structural schematic diagram of the stamped main body part 30. The stamped main body part 30 is table-shaped, including a desktop and a pillar 31, and the pillar 31 is vertical to the desktop. Generally, the pillar 31 of the stamped main body part 30 is provided with Four are respectively arranged at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com