Slicing device for bread processing

A slicing device and bread technology, which is applied in metal processing and other directions, can solve the problems of inconvenient use and low slicing efficiency, and achieve the effects of convenient disassembly, increased friction, and avoiding sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

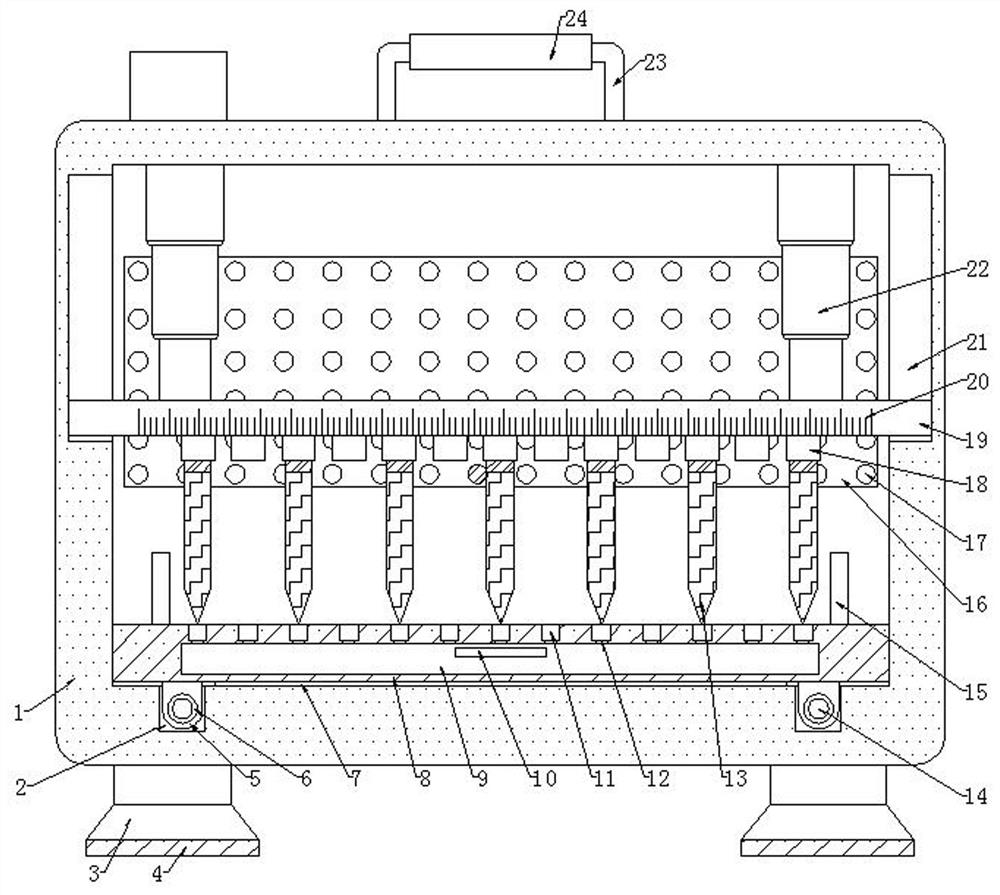

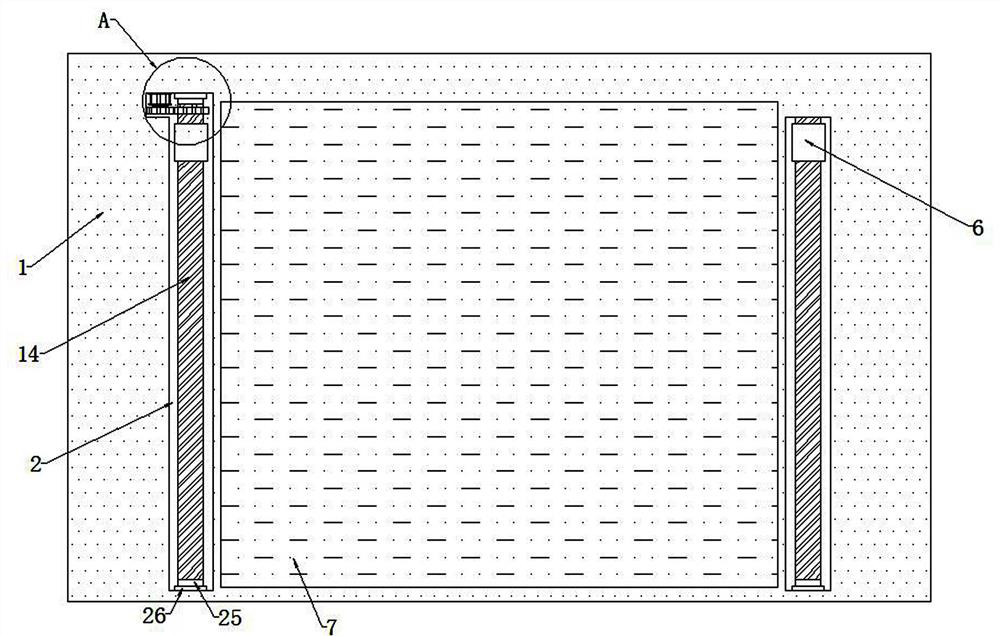

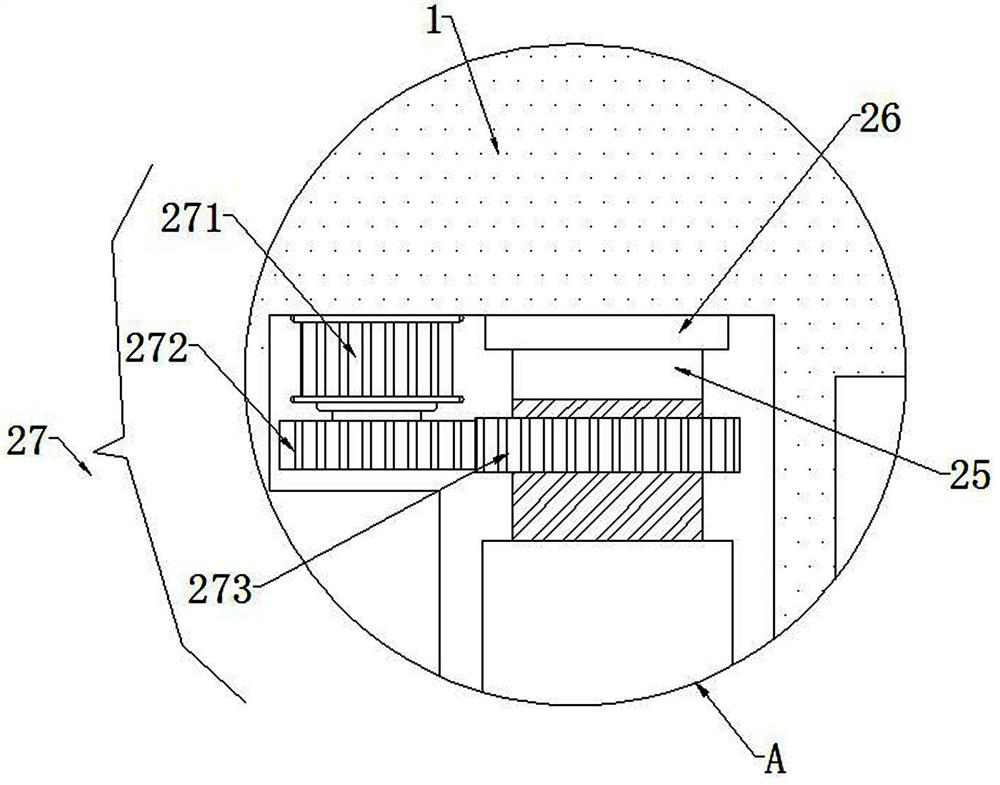

[0025] see Figure 1-4 , the present invention provides the following technical solutions: a slicer for bread processing, comprising a box body 1, the bottom of the inner wall of the box body 1 is provided with a first groove 2, and the front side and the rear side of the inner wall of the first groove 2 are fixedly connected There is a bearing 26, the bearing 26 is pierced with a rotating shaft 25, the rotating shaft 25 is fixedly connected with a threaded column 14, the surface of the threaded column 14 is fixedly connected with a driving assembly 27, and the driving assembly 27 is fixedly connected to the bottom of the inner wall of the first groove 2, The drive assembly 27 includes a drive motor 271, the drive assembly 27 is fixedly connected to the bottom of the first groove 2 inner wall, the output shaft of the drive motor 271 is fixedly connected with a driving gear 272, and the surface of the drive gear 272 is meshed with a driven gear 273. The driving gear 273 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com