A hydraulic system and control method for loading test

A hydraulic system and loading test technology, applied in the field of hydraulic control, can solve problems such as inability to guarantee safety, long-term pressure holding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A hydraulic system for a loading test according to an embodiment of the present invention will be described below with reference to the accompanying drawings.

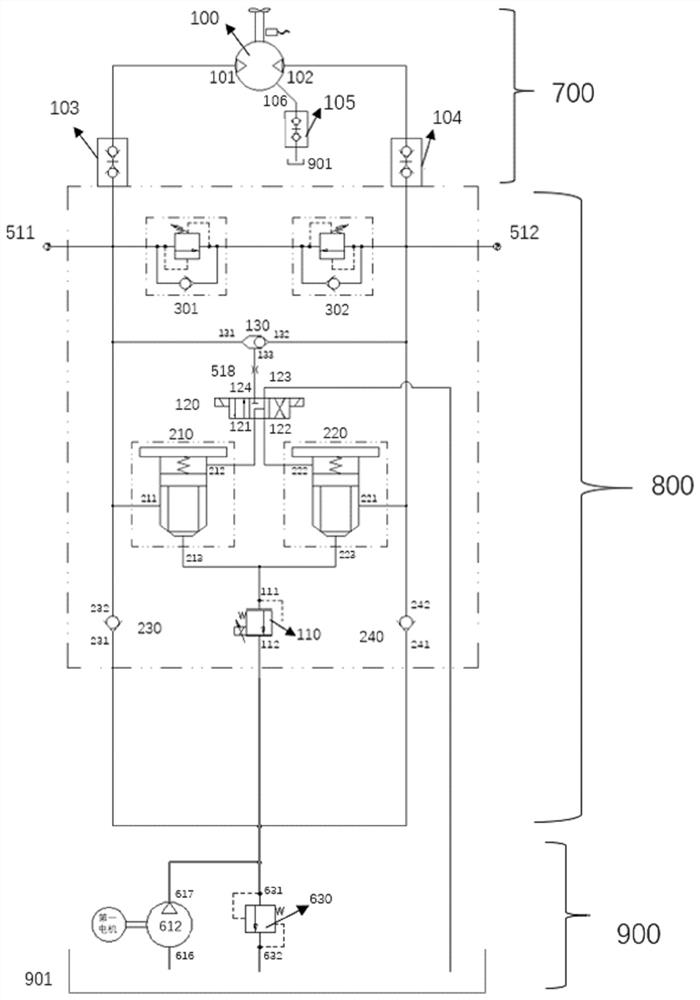

[0061] Such as figure 1 As shown, a hydraulic system for a loading test according to an embodiment of the present invention includes a loading input module 700, a hydraulic loading module 800, and a hydraulic auxiliary module 900. The hydraulic auxiliary module 900 includes a charge pump 612, an overflow valve 630 and Oil tank 901; the loading input module 700 includes a loading motor 100; the hydraulic loading module 800 includes an electric proportional overflow valve 110, an electromagnetic reversing valve 120, a shuttle valve 130, a first cartridge valve 210, a second cartridge valve Install valve 220, first one-way valve 230, second one-way valve 240 and controller 500;

[0062] The first valve port 211 and the second valve port 212 of the first cartridge valve 210 are respectively connected to the first o...

Embodiment 2

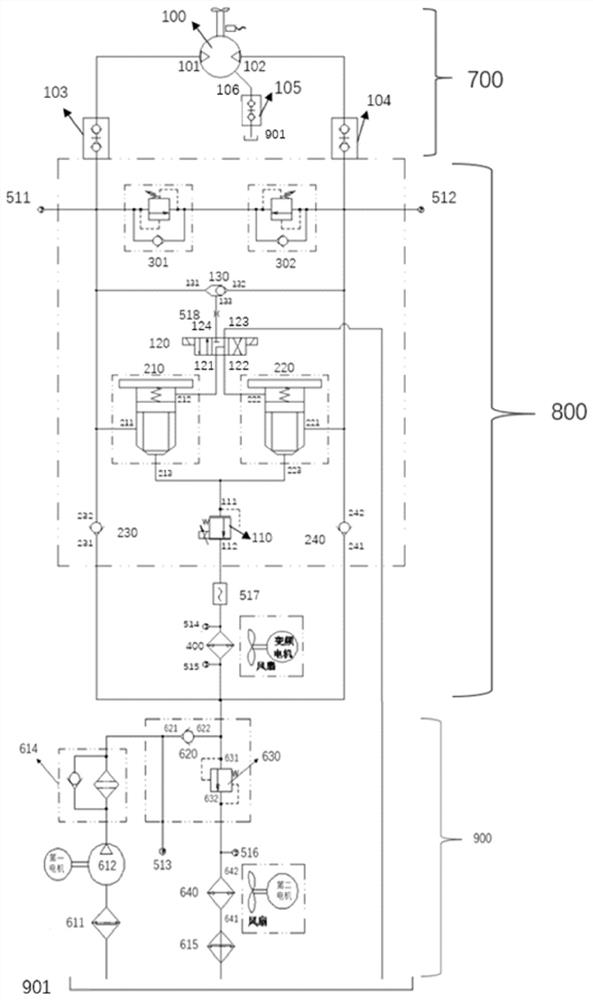

[0083] Such as figure 2 As shown, a hydraulic system for a loading test according to another embodiment of the present invention includes a loading input module 700 , a hydraulic loading module 800 , and a hydraulic auxiliary module 900 .

[0084] 1) The loading input module 700 includes a loading motor 100 .

[0085] 2) The hydraulic loading module 800 includes an electric proportional relief valve 110, an electromagnetic reversing valve 120, a shuttle valve 130, a first cartridge valve 210, a second cartridge valve 220, a first one-way valve 230, a second Check valve 240, first radiator 400 and controller 500;

[0086] The first valve port 211 and the second valve port 212 of the first cartridge valve 210 are respectively connected to the first oil port 101 of the loading motor and the first oil outlet 121 of the electromagnetic reversing valve 120;

[0087] The first valve port 221 and the second valve port 222 of the second cartridge valve are respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com