Reinforced concrete prefabricated part strength detection method

A reinforced concrete, strength detection technology, applied in the direction of strength characteristics, using stable tension/pressure test material strength, measuring device, etc. and other problems, to achieve the effect of increasing detection accuracy and detection effect, increasing positioning accuracy, and increasing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

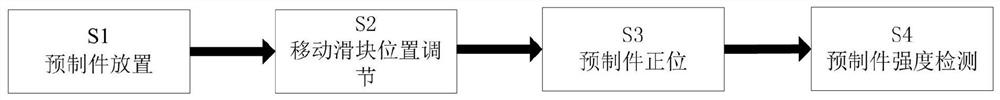

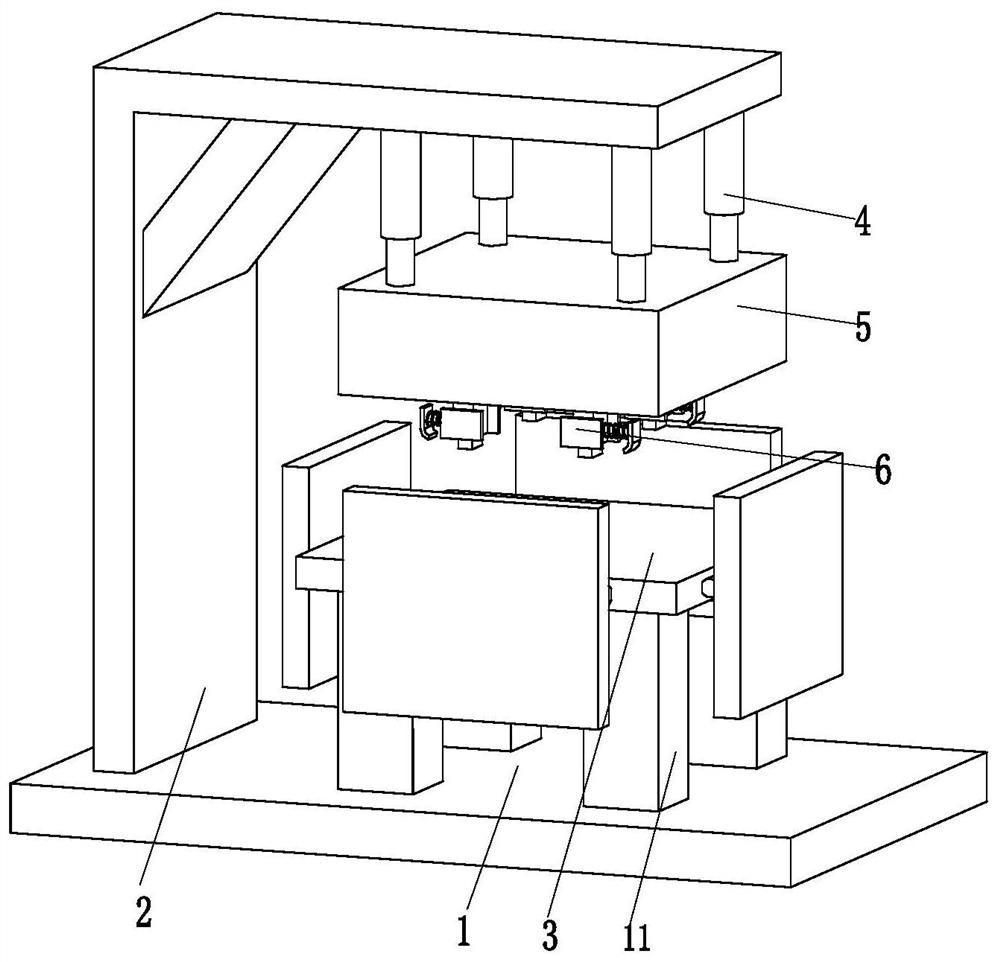

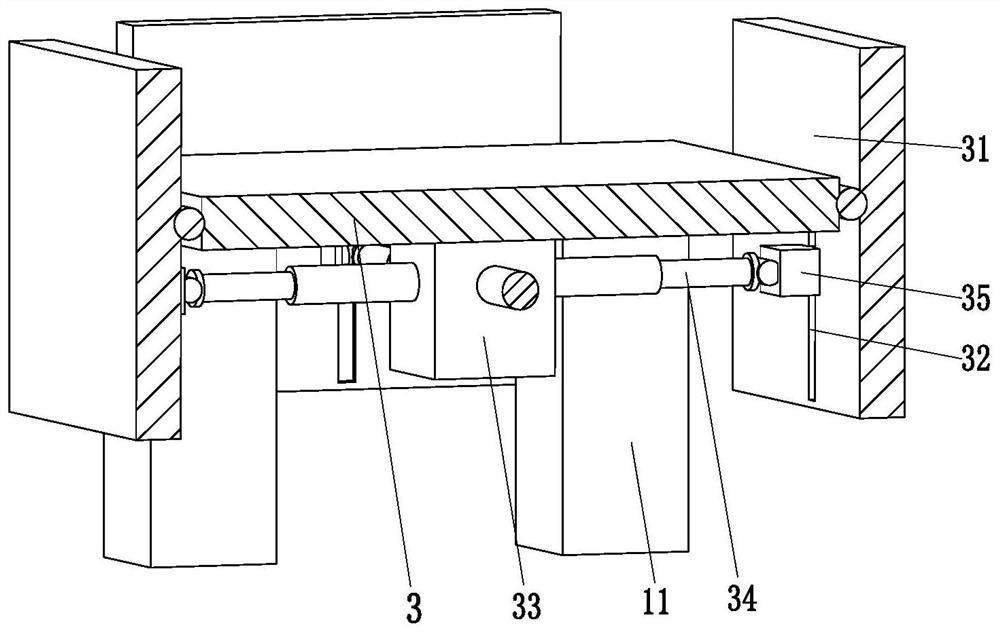

[0038] Such as Figure 2-8 As shown, a method for detecting the strength of a reinforced concrete prefabricated part. The method for detecting the strength of a reinforced concrete prefabricated part adopts the following prefabricated part strength detecting device. 4 and the extruding body 5, the upper side of the middle part of the bottom plate 1 is equipped with a supporting platform 3 through the supporting column 11, and the extruding body 5 is distributed directly above the supporting platform 3, and the upper side of the extruding body 5 is connected to the The telescoping ends of the hydraulic cylinder 4 are connected, the fixed end of the hydraulic cylinder 4 is installed on the down-pressing bracket 2 of the L-shaped structure, and the bottom of the down-pressing bracket 2 is installed on the upper side of the base plate 1. The present invention can evenly arrange the middle part with The strength of the concrete prefabricated part of the slot hole is tested. First, ...

Embodiment 2

[0053] In this embodiment, on the basis of Embodiment 1, a locking rod 58 for limiting the positioning rod 62 is provided;

[0054] The outer wall of the vertical section of the U-shaped groove 51 is provided with an adjustment groove 56, the adjustment groove 56 runs through the extrusion body 5, a locking sleeve 57 is arranged in the adjustment groove 56, a locking rod 58 is arranged in the locking sleeve 57, and the locking rod 58 passes through the normal position follower block 61, and the position corresponding to the locking rod 58 on the normal position rod 62 is provided with a locking groove 621, the locking rod 58 is inserted in the locking groove 621, and the locking sleeve 57 is provided with a locking sleeve 57 for locking The anti-slip ring rubber pad of the rod 58, the ring rubber pad prevents the locking rod 58 from moving under the action of no external force; by pressing the locking rod 58 inwards, its inner end can be inserted into the locking groove 621, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com