Manufacturing method of custom printing manicure

A production method and custom technology, applied in manicure, pedicure, medical formula, etc., can solve the problems of poor creativity, small selection range of patterns, simple painted patterns, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

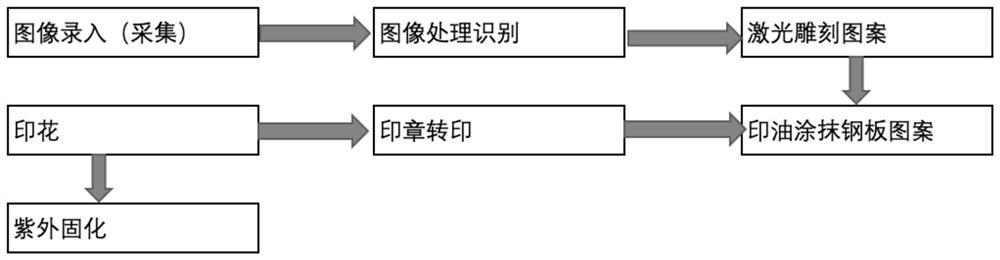

[0023] A method for making custom printed nail art, comprising the steps of:

[0024] Step 1. Enter the butterfly pattern into the database, and then perform pattern processing to identify the shape of the butterfly pattern for typesetting, and then use a laser engraving machine to engrave the typesetting butterfly pattern on the steel plate with an engraving depth of 0.07mm to obtain an engraved steel plate for use;

[0025] Step 2. Apply the nail polish on the engraved steel plate, scrape the nail polish with a scraper and let the nail polish penetrate into the pattern groove of the engraved steel plate;

[0026] Step 3. Transfer the butterfly nail art pattern on the steel plate to the nail through a soft silicone stamp. The material of the stamp head is ethylene propylene rubber. After the butterfly pattern decoration is completed, seal it, and then cure the butterfly nail art pattern with a UV lamp to obtain a customized Printed nail art. Specifically, the nail polish inc...

Embodiment 2

[0028] A method for making custom printed nail art, comprising the steps of:

[0029] Step 1. Enter the self-portrait pattern into the database, and then carry out pattern processing to identify the shape of the self-portrait pattern for typesetting, and then engrave the typesetting self-portrait pattern on the steel plate with a laser engraving machine. The engraving depth is 0.09mm, and the engraved steel plate is obtained. use;

[0030] Step 2. Apply the nail polish on the engraved steel plate, scrape the nail polish with a scraper and let the nail polish penetrate into the pattern groove of the engraved steel plate;

[0031] Step 3. Transfer the self-portrait manicure pattern on the steel plate coated with oil to the nail through a soft silicone stamp. The material of the stamp head is butyl rubber. After the self-portrait pattern is decorated, it is sealed, and then the self-portrait manicure pattern is cured under a UV lamp. , get custom printed nail art.

[0032] Spec...

Embodiment 3

[0034] A method for making custom printed nail art, comprising the steps of:

[0035] Step 1. Enter the leaf pattern into the database, and then perform pattern processing to identify the shape of the leaf pattern for typesetting, and then use the laser engraving machine to engrave the typesetting leaf pattern on the steel plate with an engraving depth of 0.1mm to obtain an engraved steel plate for use;

[0036] Step 2. Apply the nail polish on the engraved steel plate, scrape the nail polish with a scraper and let the nail polish penetrate into the pattern groove of the engraved steel plate;

[0037] Step 3. Transfer the oil-coated leaf nail art pattern on the steel plate to the nail through a soft silicone stamp. The stamp head is made of chlorohydrin rubber. After the leaf pattern decoration is completed, seal it, and then cure the leaf nail art pattern in a UV lamp. Get a custom print manicure.

[0038] Specifically, the nail polish includes the following components by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com