Paper treatment device

A paper processing device and paper technology, applied in book binding, book binding flattening machine, printing, etc., can solve the problems of large configuration space, kicking out, unable to flatten paper, etc., and achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

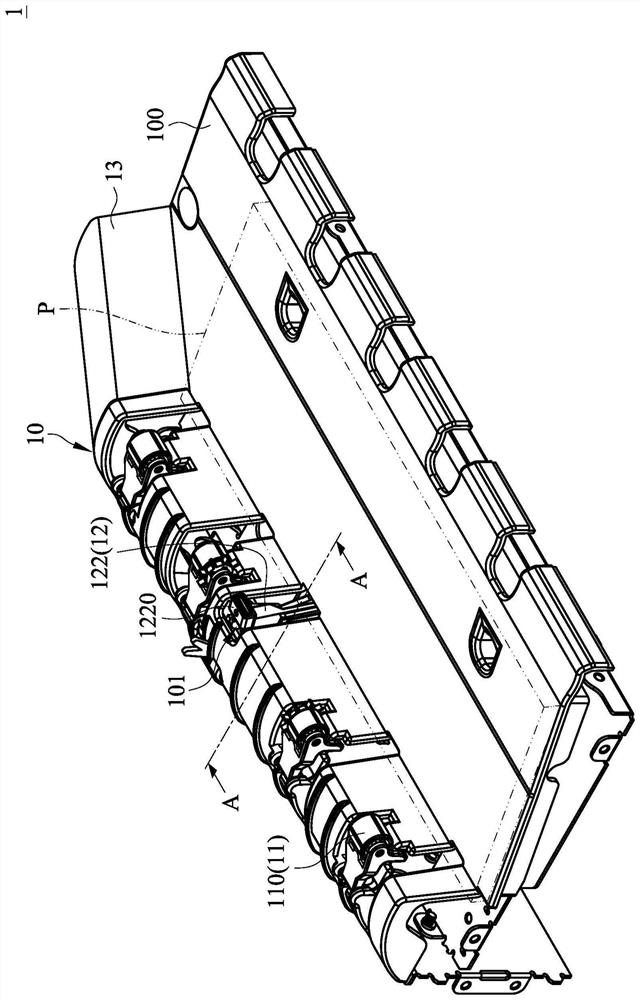

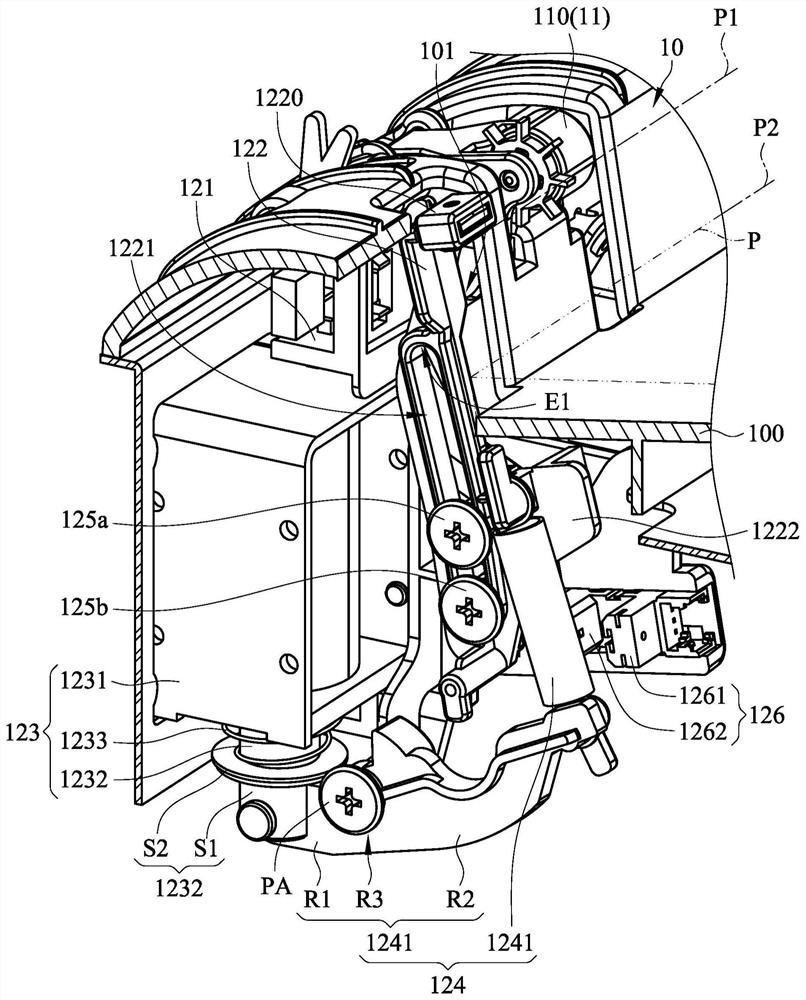

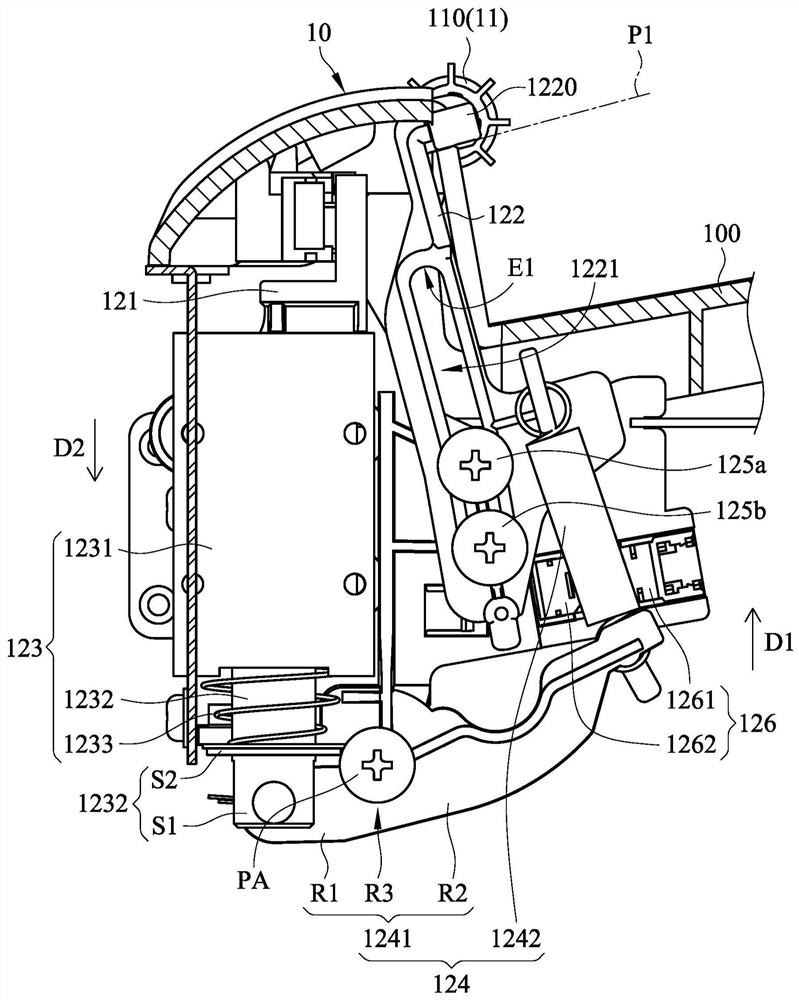

[0062] see Figure 1 to Figure 2 , figure 1 It is a schematic diagram of the appearance structure of a paper processing device according to an embodiment of the present invention. figure 2 along figure 1 Schematic cross-sectional view of line AA shown. The paper processing device 1 of this embodiment is, for example, arranged above or on both sides of a printing device (not shown). Binding or punching, etc. Such as figure 1 and figure 2 As shown, the paper processing device 1 of this embodiment includes a housing 10 , a transport roller set 11 and a paper pressing device 12 . The casing 10 includes a paper loading platform 100 extending outward. The conveying roller set 11 is disposed on the casing 100 and is used for conveying the papers P from the printing device to the paper placing platform 100 . The paper pressing device 12 is disposed below the housing 10 , and the paper pressing device 12 includes a support frame 121 , a paper pressing rod 122 , a driving asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com