Teflon cloth filler strip retracting and releasing mechanism, stitch welding machine and filler strip replacing method

A technology of retractable mechanism and replacement method, which is applied to winding strips, photovoltaic power generation, electrical components, etc., can solve problems such as inconvenience of operation and potential safety hazards, and achieve the effects of high safety, ensuring installation reliability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

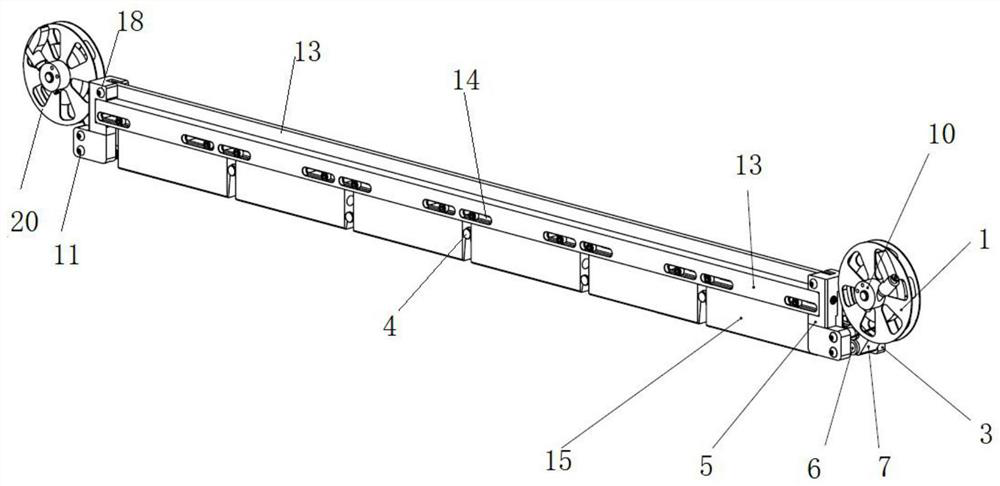

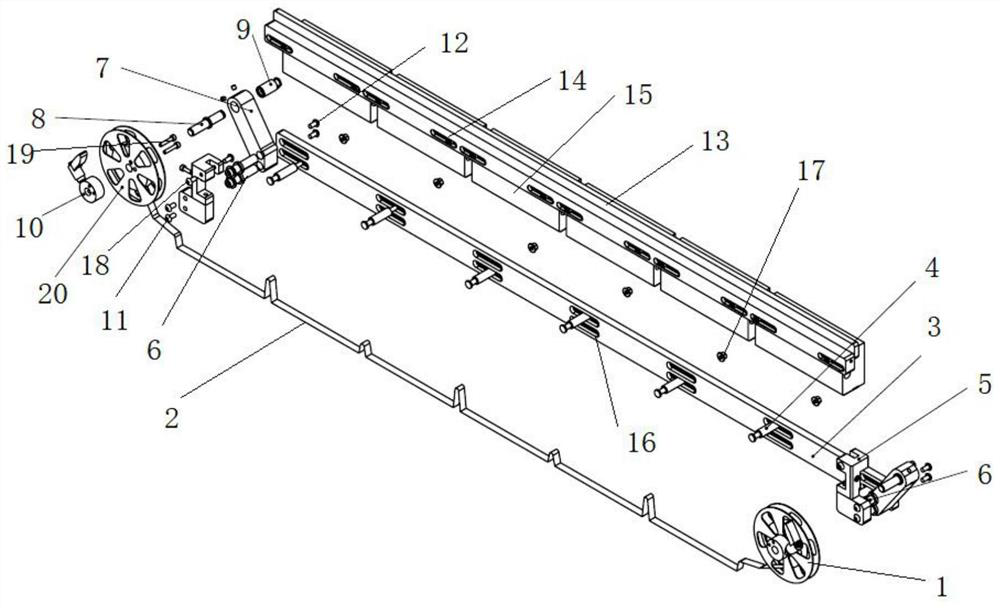

[0037] A specific embodiment of the present invention discloses a retractable mechanism for a PTFE cloth pad installed at the position of the welding head of a stitch welding machine, such as Figure 1-Figure 2 As shown, it includes: base plate 3, guide column 4 installed on the base plate 3, fixed block 5 and tetrafluoro tape reel for fixing the whole retractable mechanism on the welding head bracket 13, and four fluoro tape reels are wound in the tetrafluoro tape reel Fluorine fabric roll is PTFE tape 2. Two PTFE tape reels are installed at the two ends of the welding head support 13, wherein, a PTFE tape reel is used as a discharge tape reel, and another PTFE tape reel is used as a receiving tape reel, by rotating two PTFE tape reels, can Make the tetrafluoro tape 2 slide relative to the welding head 15 to complete the replacement of the tetrafluoro tape 2 .

[0038] Specifically, two fixed blocks 5 are installed at the two ends of the welding head support 13, and the two ...

Embodiment 2

[0061] A lap welding machine, the PTFE pad retractable mechanism in Example 1 is installed on the welding head bracket, used to replace the PTFE cloth pad on the welding head 15, instead of manually pasting the four fluoro cloth pads on the welding head. Operation of fluorocloth tape.

Embodiment 3

[0063] A method for replacing the tetrafluoro cloth gasket of welding head of a lap welding machine, adopting the tetrafluoro cloth gasket retractable mechanism in embodiment 1 to replace the tetrafluoro cloth gasket, the method for replacing the tetrafluoro cloth gasket includes the following steps:

[0064] Step S1: Install the retractable mechanism of the PTFE pad on the welding head bracket 13 of the stitch welding machine;

[0065] Step S2: When the PTFE cloth needs to be replaced, open the fixed ring 10; rotate the PTFE tape reel to take in and out the material, and the tape reel is used to discharge the material while the tape reel is receiving the material to complete the PTFE cloth retracting and unwinding;

[0066] Step S3: Lock the fixing ring 10, and now the PTFE tape reel rotates; the PTFE tape 2 is tensioned on the welding head 15.

[0067] In the step S1, the tetrafluoro tape 2 is wound on the first tape reel 1, and the end of the tetrafluoro tape 2 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com