Fabricated building external wall insulation system and assembly method thereof

A technology for building exterior walls and thermal insulation systems. It is applied in thermal insulation, buildings, and building components. It can solve problems such as hollow structures in thermal insulation systems and easy bending and fracture of external wall panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

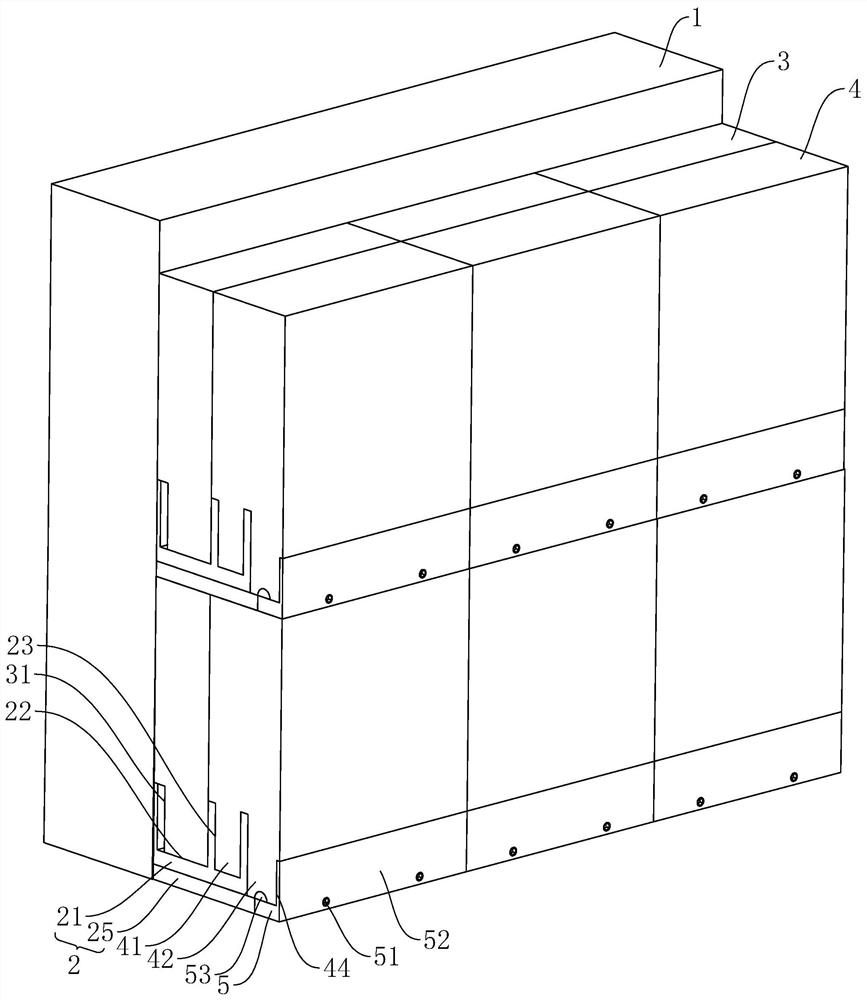

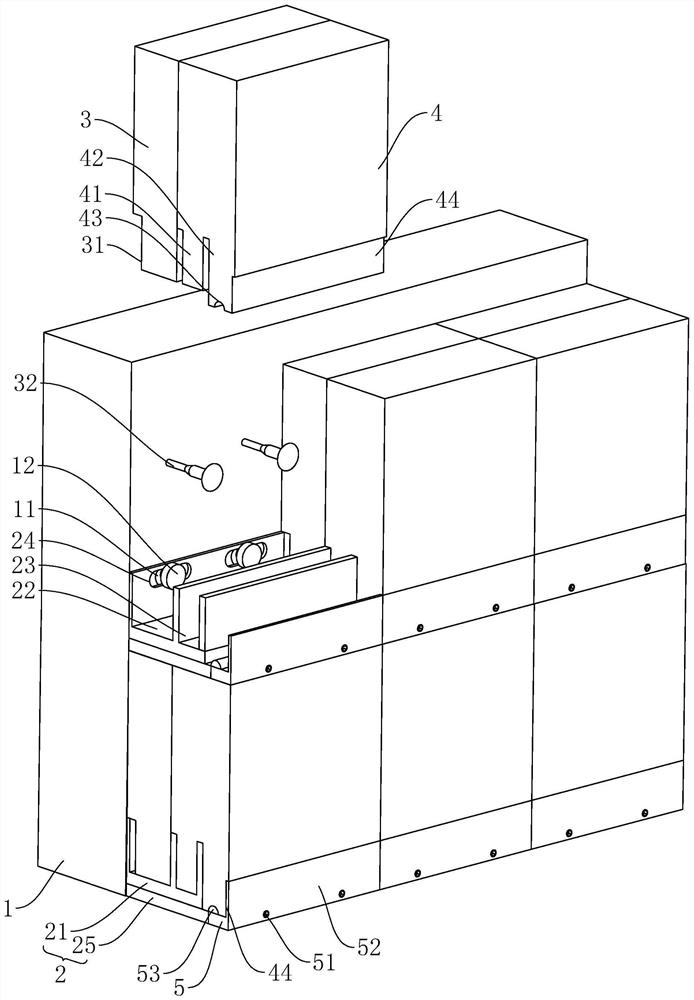

[0037] The following is attached Figure 1-2 The application is described in further detail.

[0038] The embodiment of the present application discloses a prefabricated building exterior wall thermal insulation system. refer to figure 1 , a prefabricated building exterior wall thermal insulation system includes several installation frames 2 and thermal insulation units 3 installed on the wall 1 , and an external wall panel 4 installed on the side of the thermal insulation unit 3 away from the wall 1 . The installation frame 2 is installed on the wall body 1, and the heat preservation unit 3 and the exterior wall panel 4 are positioned and installed through the installation frame 2, and after the exterior wall panel 4 is installed, the heat preservation unit 3 and the exterior wall panel 4 are arranged in contact with each other.

[0039] refer to figure 1 and figure 2 A number of threaded sleeves 11 are pre-embedded at fixed points on the wall 1 , one end of the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com