Edge sealing structure of steel structure wall surface maintenance system and installation method thereof

A technology for maintaining systems and installation methods, which is applied to building components, building structures, windows/doors, etc., and can solve problems such as low strength, uneven bulges, and many leakage points of fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

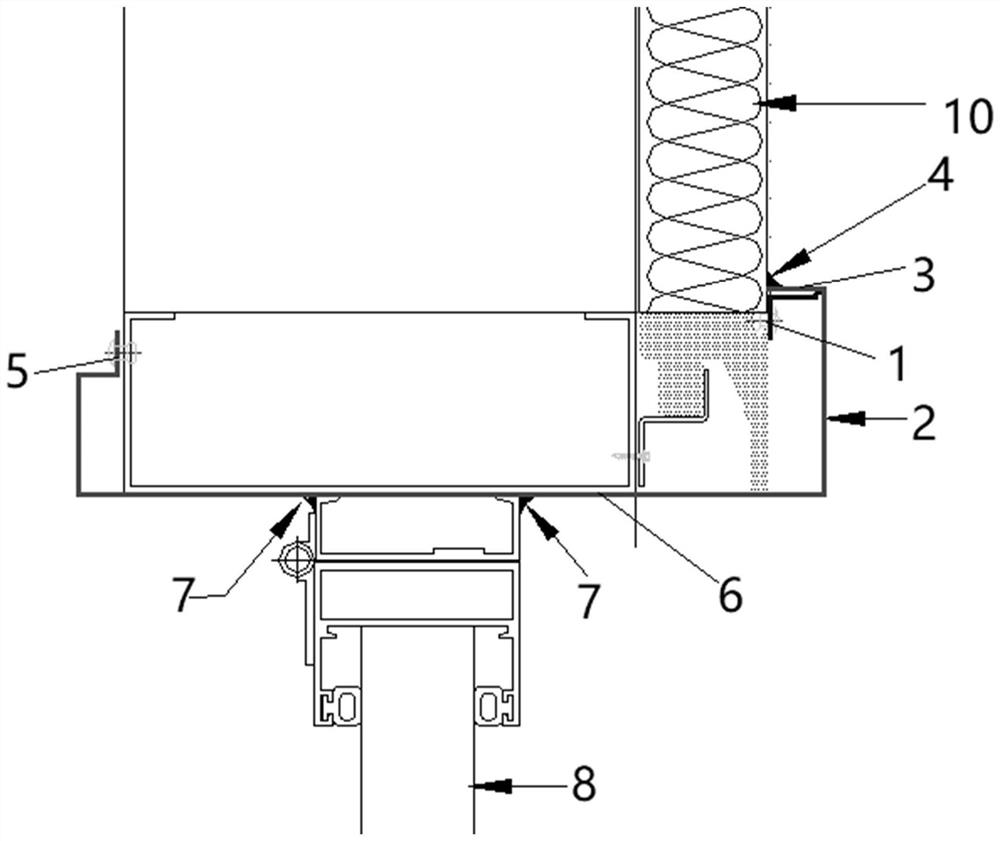

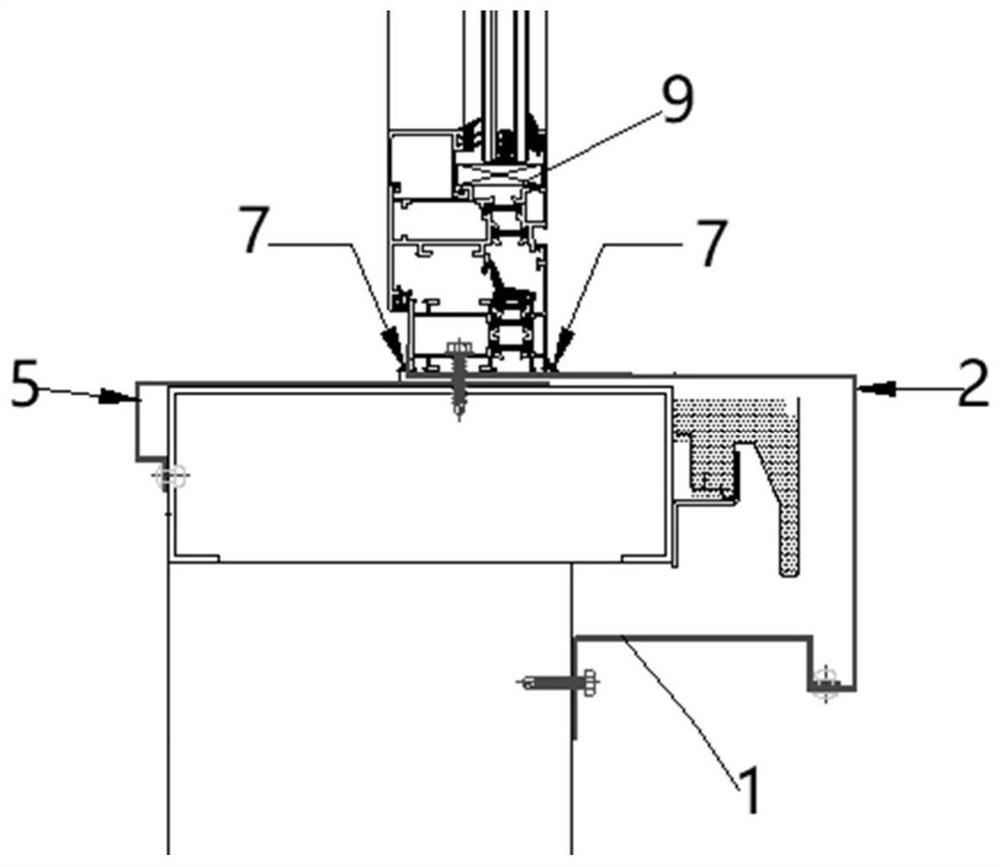

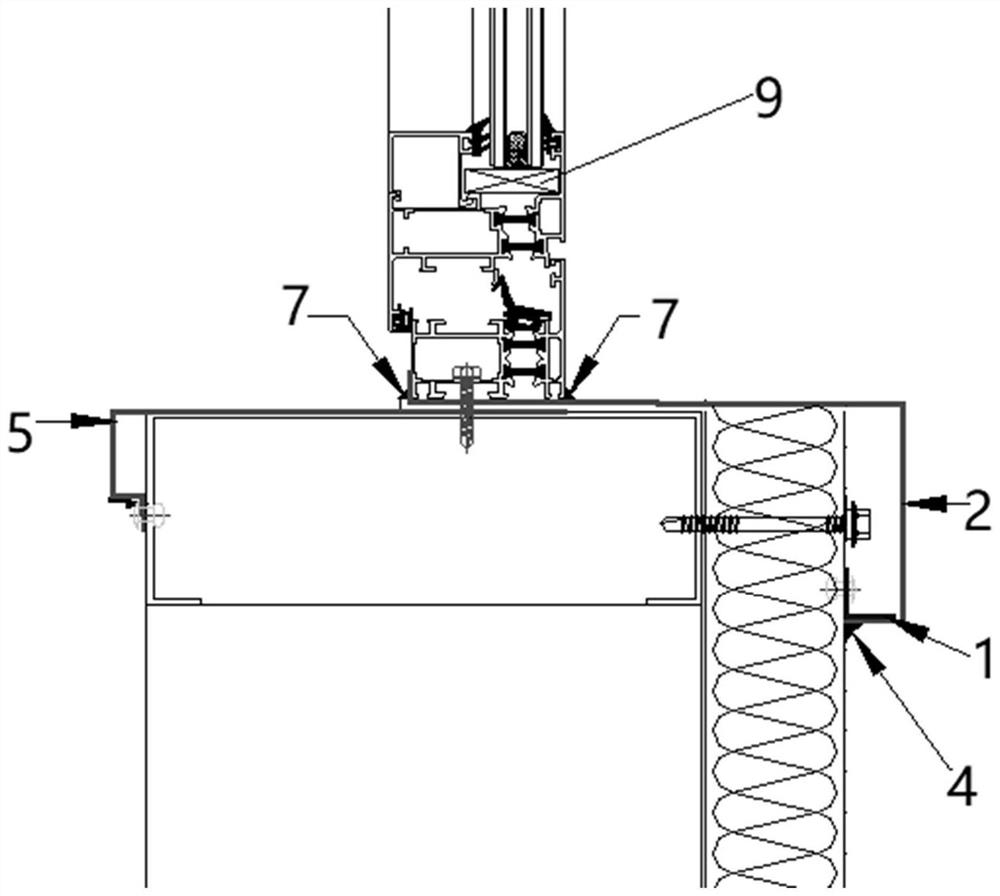

[0027] Such as figure 1 As shown in the figure, an edge sealing structure of a steel structure wall maintenance system includes an edge-receiving bracket 1 and an edge-folding sealing frame 2. The edge-receiving bracket 1 adopts an L-shaped bracket, and one side of the edge-receiving bracket 1 is fastened to the outer wall. , the two ends of the flange sealing frame 2 are respectively provided with an inner flange 3 and an inner contact edge 5, the end of the inner flange 3 is in contact with the end of the outer wall surface, and the inner surface of the inner flange 3 is in contact with the other side of the edge receiving bracket 1 Edge contact, through the edge receiving bracket 1, the pair of edge sealing frame 2 forms a supporting structure at the outer wall, the inner contact edge 5 on the edge sealing frame 2 is fixedly connected with the inner wall surface, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com