Rock cross-cut coal uncovering method based on controllable shock wave permeability improvement

A technology of coal excavation and shock wave in Shimen, which is used in earth-moving drilling, ground mining, mining equipment, etc., can solve the problems of long time, high cost, and unsatisfactory effect of eliminating outburst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

[0044] The Shimen coal removal method based on the controllable shock wave anti-reflection method of the present invention comprises the following steps:

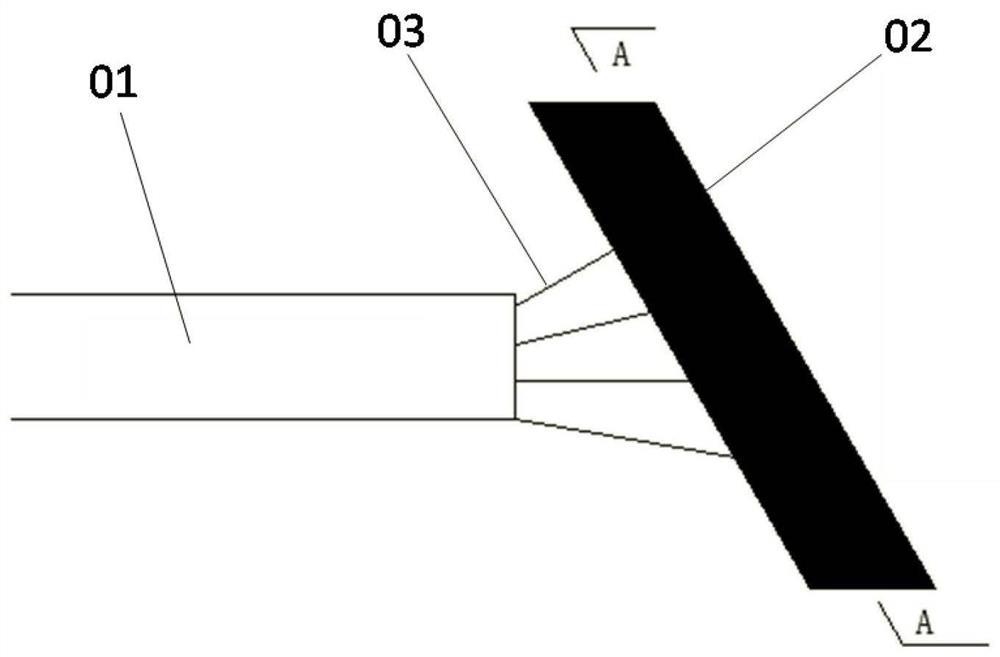

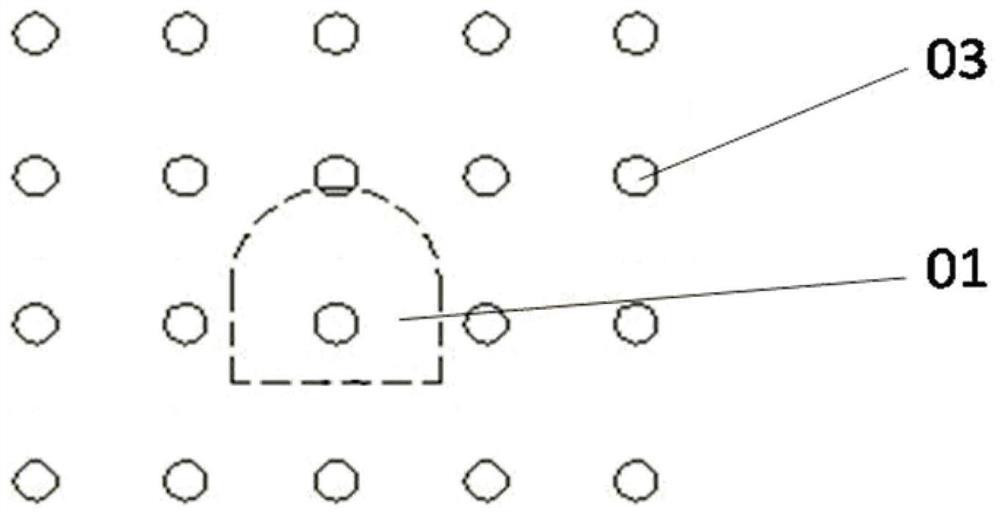

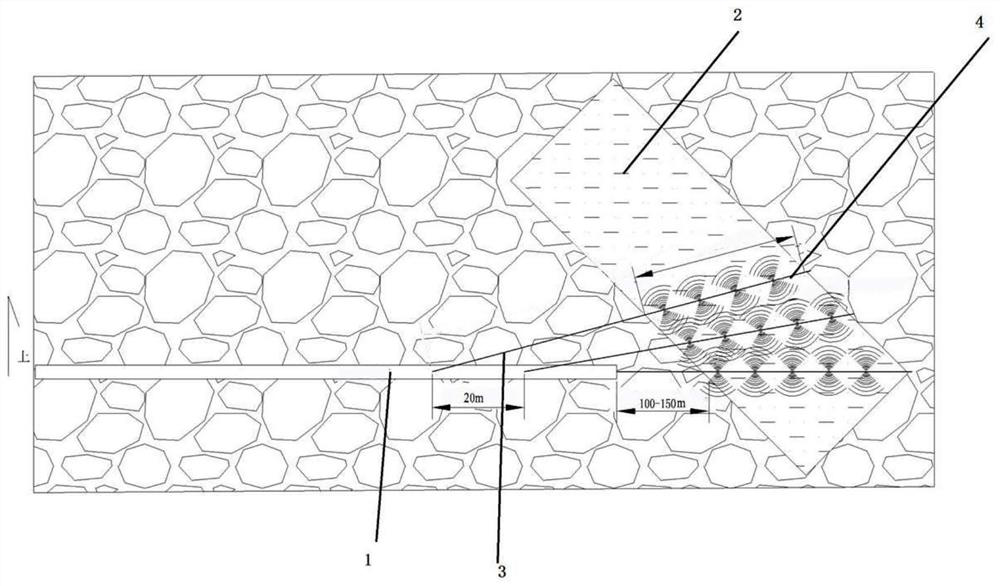

[0045] 1) Determine the location of the roadway 1. When the roadway 1 is excavated to a distance of 100-150m from the coal seam 2 to be exposed, 3-5 anti-reflection drilling holes 3 are constructed from the rock layer of the roadway 1 to the coal seam 2 to be exposed. The hole 3 passes through the coal seam 2 to be exposed at one time and then enters the rock formation. The position of the final hole needs to enter the rock formation for more than 0.5m. The penetration drilling 3 passes through the coal seam section of the coal seam 2 to be revealed as the anti-permeability operation range (ie the anti-permeability position) 4;

[0046] 2) Determine whether the coal seam 2 to be exposed is a soft coal seam, and if so, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com