Method for rapidly evaluating crystal points of hard elastic diaphragm of homo-polypropylene lithium battery

A technology of lithium battery diaphragm and homopolymerized polypropylene, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of increased filter pressure, increased frequency and cost of filter replacement, and achieves simple experimental steps and The test results are intuitive and the effect of saving evaluation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the content and use of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples.

[0045] Select different raw materials to make a preliminary judgment on the appearance, including: black spots, visible impurities, dust, and the uniformity of polypropylene particle size, etc.;

[0046] Analyze and test the physical properties of raw materials, mainly including: melt index, ash content, rebound rate, etc.;

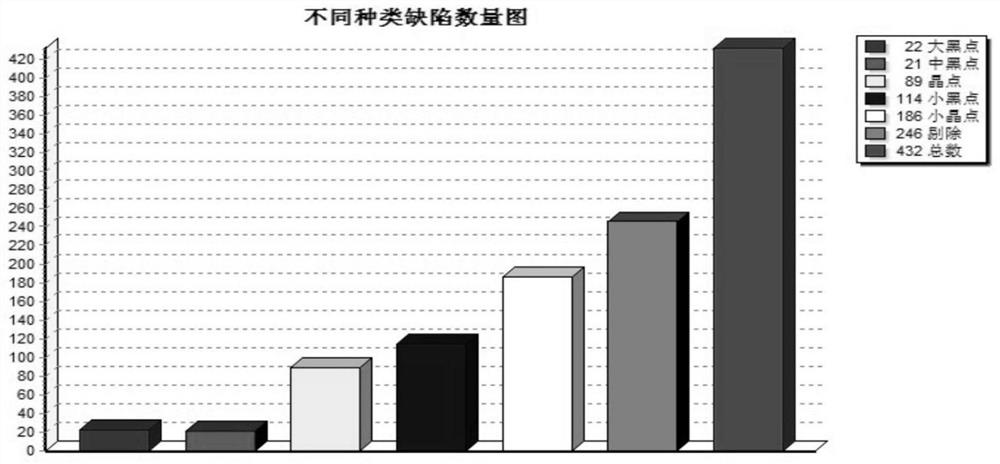

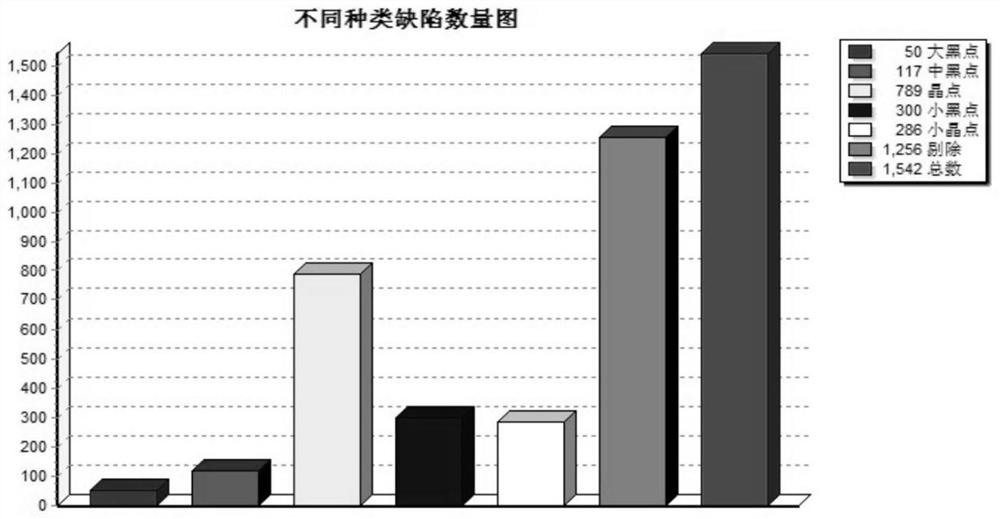

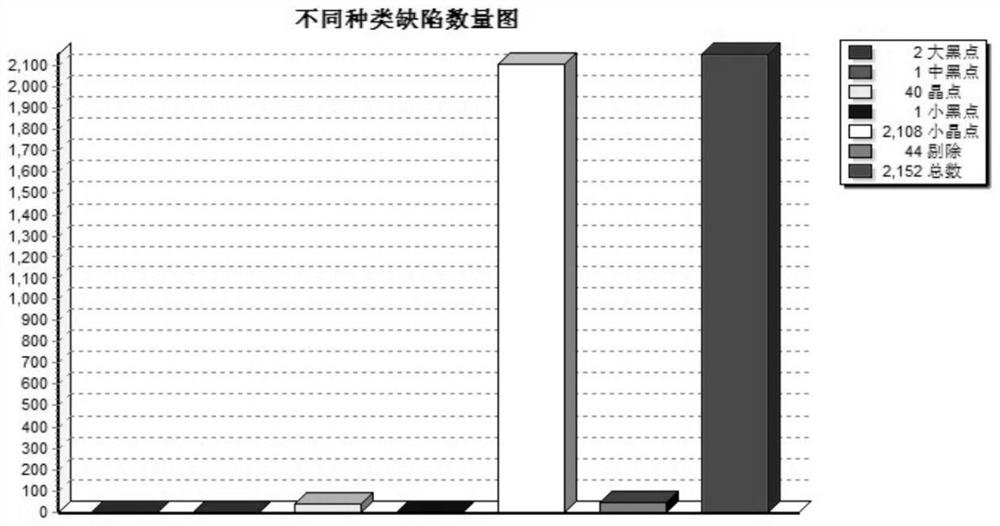

[0047] The crystal point evaluation of the special material for homopolypropylene lithium battery diaphragm is realized through the following process;

[0048] 1. Use a twin-screw extruder to extrude and cast the special material for lithium battery separators through casting rolls.

[0049] Each zone of the twin-screw extruder includes 1-9 zone barrels, 3 transition temperature zones, and 3 die head temperature zones. Preferably, the processing temperature range of the twin-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com