Digital Alloy, Digital Alloy Mid-Wave Infrared Detector

An infrared detector, digital technology, used in semiconductor devices, nanotechnology for materials and surface science, electrical components, etc., to solve problems such as reduced quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The preparation method of the infrared device of the present invention: the steps include:

[0101] 1. Load the GaSb substrate into the growth chamber of the MBE system;

[0102] 2. When the vacuum of the growth chamber is better than 1E-6torr, heat the substrate to 500-700°C to remove the residual oxide layer on the substrate surface;

[0103] 3. Lower the deoxidation temperature by 10-200°C, and grow a GaSb buffer layer with a thickness of 100-1000nm;

[0104] 4. On the basis of the buffer layer, grow a layer of heavily doped blk-InAsSb layer with a thickness of 50-1000nm as the n-type electrode of the detector;

[0105] 5. Grow a layer of non-doped blk-InAsSb with a thickness of 500-10000nm as the absorbing layer of the detector;

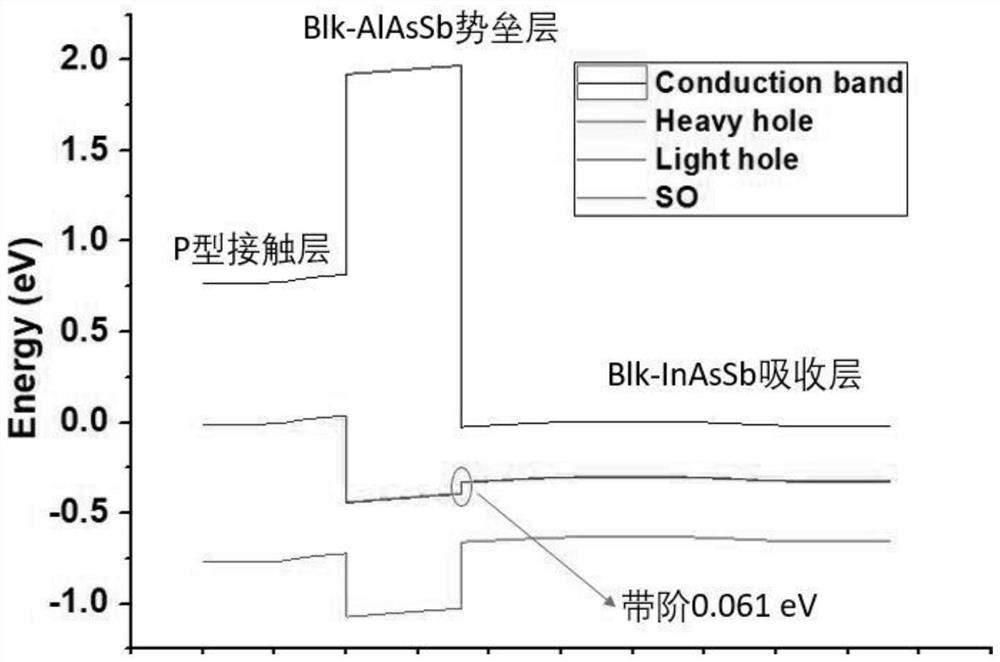

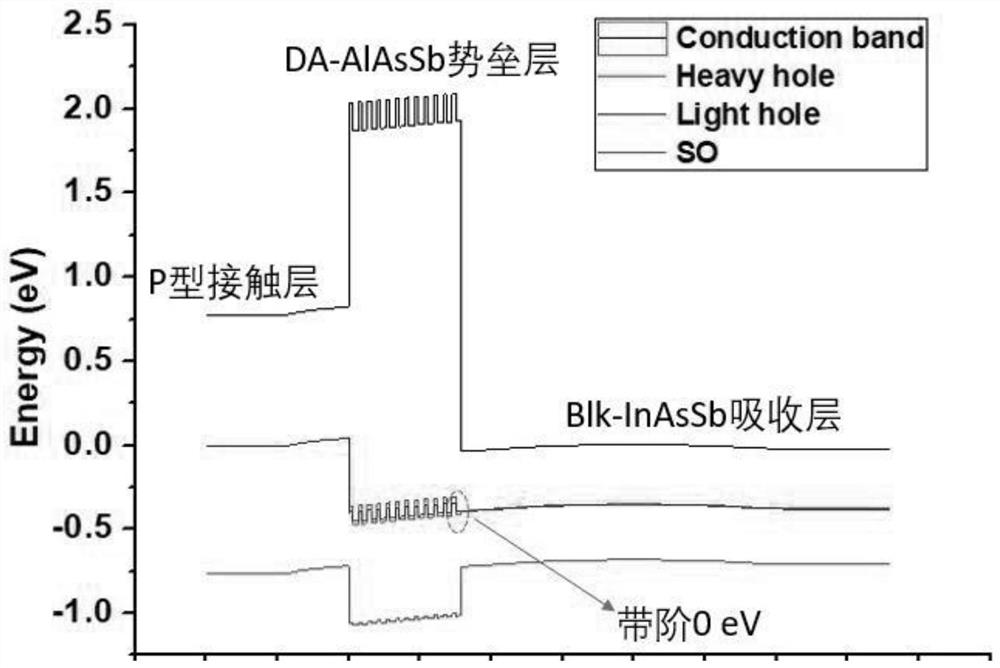

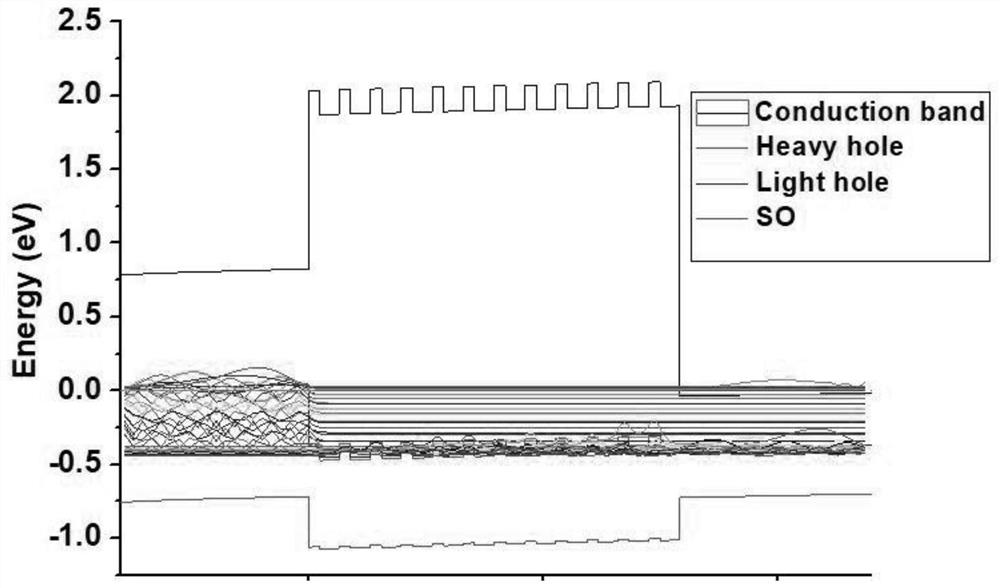

[0106] 6. Grow a layer of AlSb material with a thickness of d1, and then grow a layer of AlAsxSb1-x material with a thickness of d2 to form a basic unit with a thickness of d1+d2 to obtain DA-AlAsySb1-y. The average As composition in th...

Embodiment 2

[0113] The preparation method of the infrared device of the present invention: the steps include:

[0114] 1. Load the GaSb substrate into the growth chamber of the MBE system;

[0115] 2. When the vacuum of the growth chamber is better than 1E-6torr, heat the substrate to 500-700°C to remove the residual oxide layer on the substrate surface;

[0116] 3. Lower the deoxidation temperature by 10-200°C, and grow a GaSb buffer layer with a thickness of 100-1000nm;

[0117] 4. On the basis of the buffer layer, grow a layer of heavily doped blk-InAsSb layer with a thickness of 50-1000nm as the n-type electrode of the detector;

[0118] 5. Grow a layer of p-type lightly doped blk-InAsSb with a thickness of 500-10000nm as the absorber layer of the detector, the dopant is Be, and the p-type concentration range: 1E+15-5E+16 / cm3;

[0119] 6. Grow a layer of AlSb material with a thickness of d1, and then grow a layer of AlAsxSb1-x material with a thickness of d2 to form a basic unit wit...

Embodiment 3

[0126] The preparation method of the infrared device of the present invention: the steps include:

[0127] 1. Load the GaSb substrate into the growth chamber of the MBE system;

[0128] 2. When the vacuum of the growth chamber is better than 1E-6torr, heat the substrate to 500-700°C to remove the residual oxide layer on the substrate surface;

[0129] 3. Lower the deoxidation temperature by 10-200°C, and grow a p-type heavily doped material with a thickness of 50-1000nm as a p-type electrode layer;

[0130] 4. Grow a layer of AlSb material with a thickness of d1, and then grow a layer of AlAsxSb1-x material with a thickness of d2 to form a basic unit with a thickness of d1+d2 to obtain AlAsySb1-y. The average As composition in this digital alloy is represented by y express. The relationship between the overall average As composition y in the digital alloy and the As composition x in one layer of the basic unit is expressed as follows,

[0131] The satisfaction of this for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com