Lithium battery cathode material waste bowl and residue automatic recycling workstation

A cathode material and lithium battery technology, which is applied in the field of automatic recycling workstations for lithium battery cathode materials and waste pots and residues, can solve the problems of large dust, easy cleaning quality affected by human factors, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments are provided by way of illustration in order to fully convey the spirit of the present invention to those skilled in the art to which the present invention pertains. Therefore, the present invention is not limited to the embodiments disclosed herein.

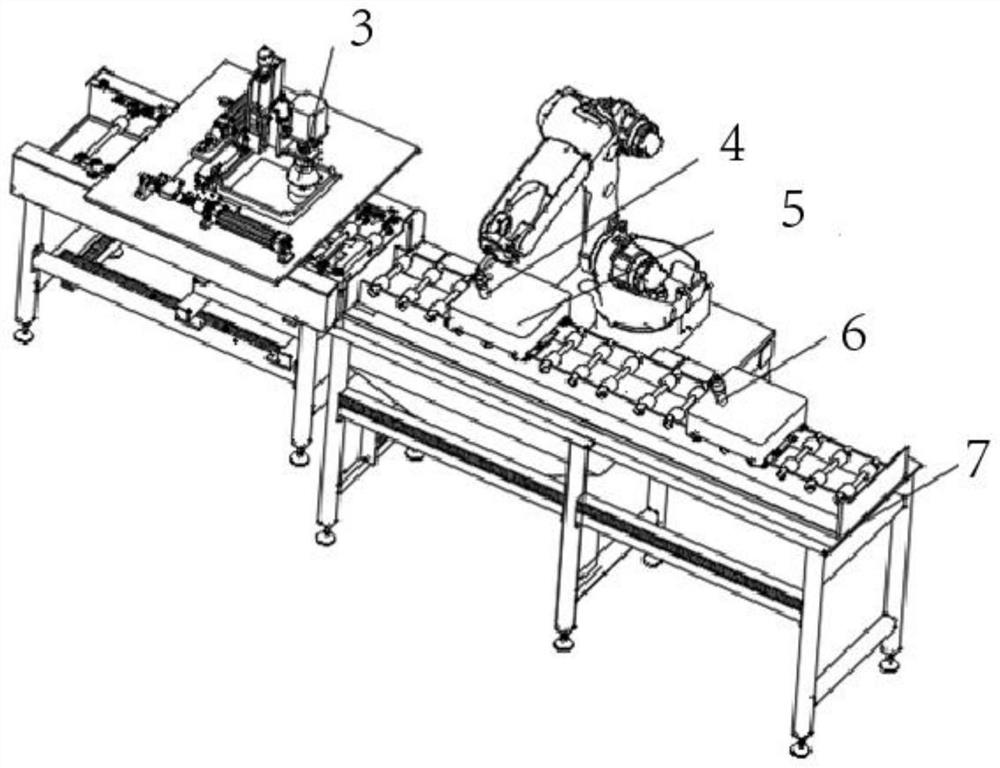

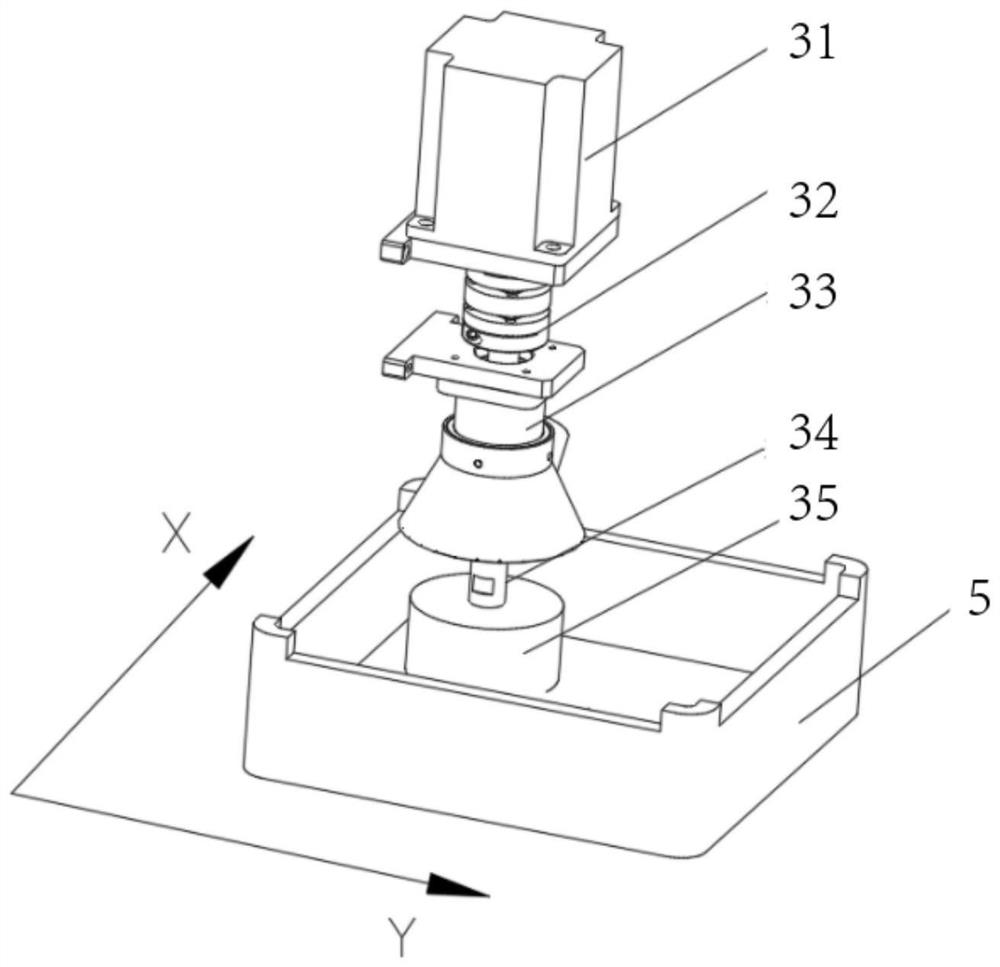

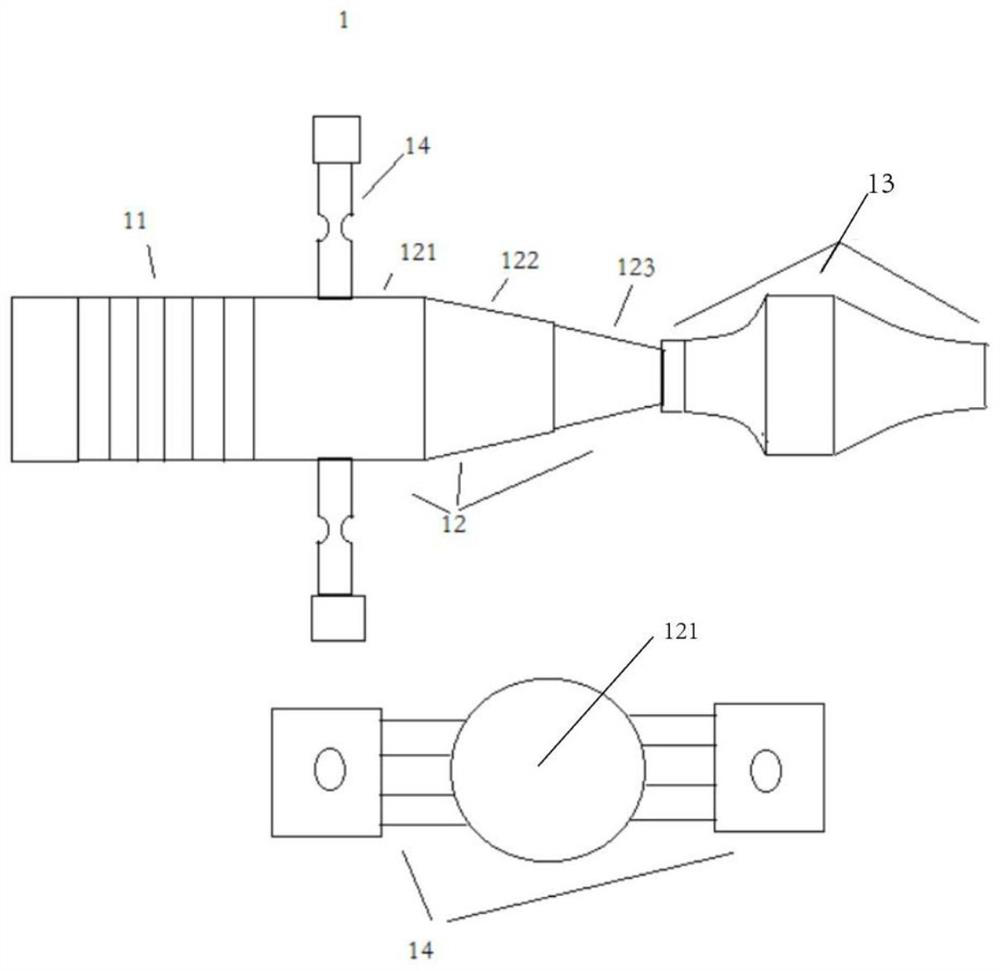

[0040] Such as figure 1 As shown, the full-automatic recovery workstation for lithium battery positive electrode material waste and old bowls and residues of the present invention can include a conveying line body 7, a frosting treatment module 3, a transfer module (not shown), an ultrasonic cleaning and air-drying module (not shown) , a surface blasting mechanism 4 and a visual inspection module 6 .

[0041] In the present invention, the waste pots are placed on the conveying line, and are firstly transported to the sanding treatment module by means of the convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com