Gel jelly containing high-content collagen

A technology of collagen peptide and jelly, which is applied in the field of gel jelly with high collagen content and jelly food processing, and can solve the problems of no Q elastic feeling, poor stability of collagen jelly, and excessive dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

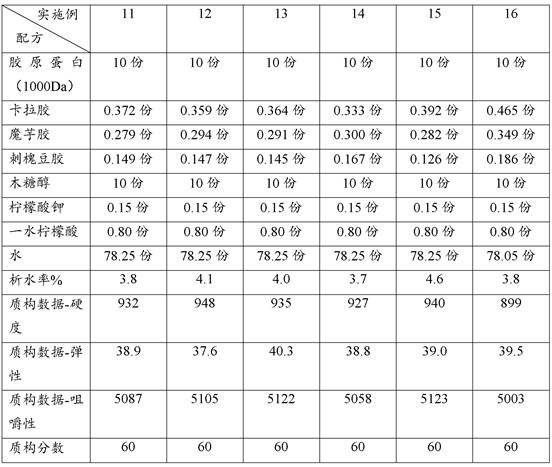

Embodiment 1-10

[0061] As described in the "Methods" section above, the jellies of Examples 1-10 (collagen peptides with different average molecular weights were used in each example) were prepared according to the formula in Table 1, and the texture score and water separation rate were evaluated. The results are shown in Table 2.

[0062] Table 1: Formulations used in Examples 1-10

[0063] formula number of copies Proportion Collagen Peptides 10.0 10.0% carrageenan 0.465 0.465% Konjac Gum 0.349 0.349% Locust Bean Gum 0.186 0.186% Xylitol 10.0 10.0% potassium citrate 0.15 0.15% Citric acid monohydrate 0.80 0.80% water 78.05 78.05% total 100.00 100.00%

[0064] Table 2: Water separation rate and texture scoring results of Examples 1-10

[0065] Example 1 2 3 4 5 6 7 8 9 10 Collagen peptide molecular weight / Da 300 500 700 1000 1600 1800 2000 3000 4000 5000 Water separation ...

Embodiment 11-25

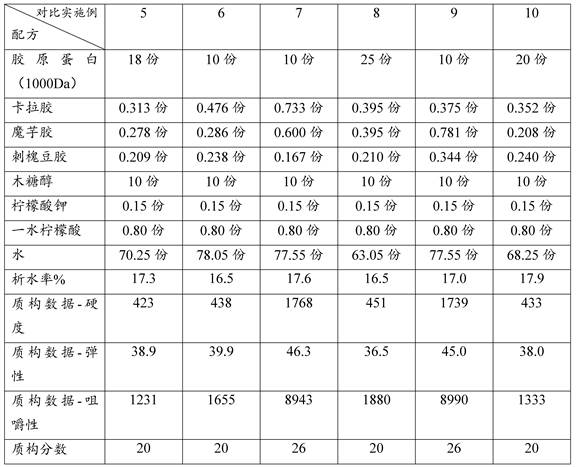

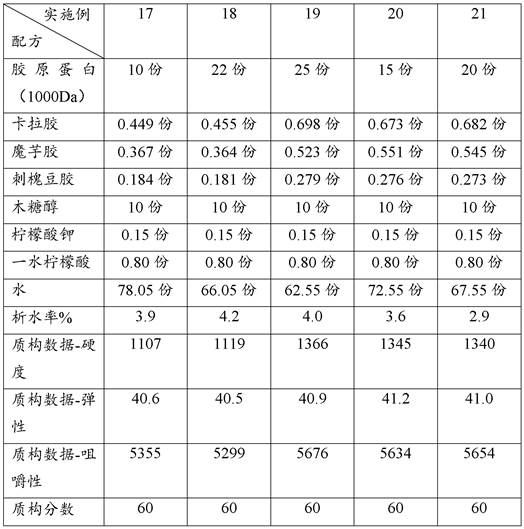

[0069] As described in the "Methods" section above, the jellies of Examples 11-25 were prepared according to the formulations in Tables 3-5 and evaluated for texture score and water separation rate.

[0070] Table 3: The formulations of Examples 11-16 and the water separation rate and texture score results

[0071]

[0072] Table 4: The formulations of Examples 17-21 and the water separation rate and texture score results

[0073]

[0074] Table 5: The formulations of Examples 22-25 and the water separation rate and texture score results

[0075]

[0076] As can be seen from Examples 11-25, when the specific ratio between carrageenan, konjac gum and locust bean gum and the molecular weight of collagen peptides meet a specific range, the water analysis of the jelly prepared by them The yield is significantly reduced, the stability is significantly improved, the taste is Q-bomb, and the chewing feeling is strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com