Coiled plate type self-heating catalytic oxidizer

A catalytic oxidizer, rolled plate technology, applied in indirect heat exchangers, heat exchanger types, chemical instruments and methods, etc., can solve the problems of bulky device, high energy consumption, complex structure, etc., to achieve compact device structure, The effect of load reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

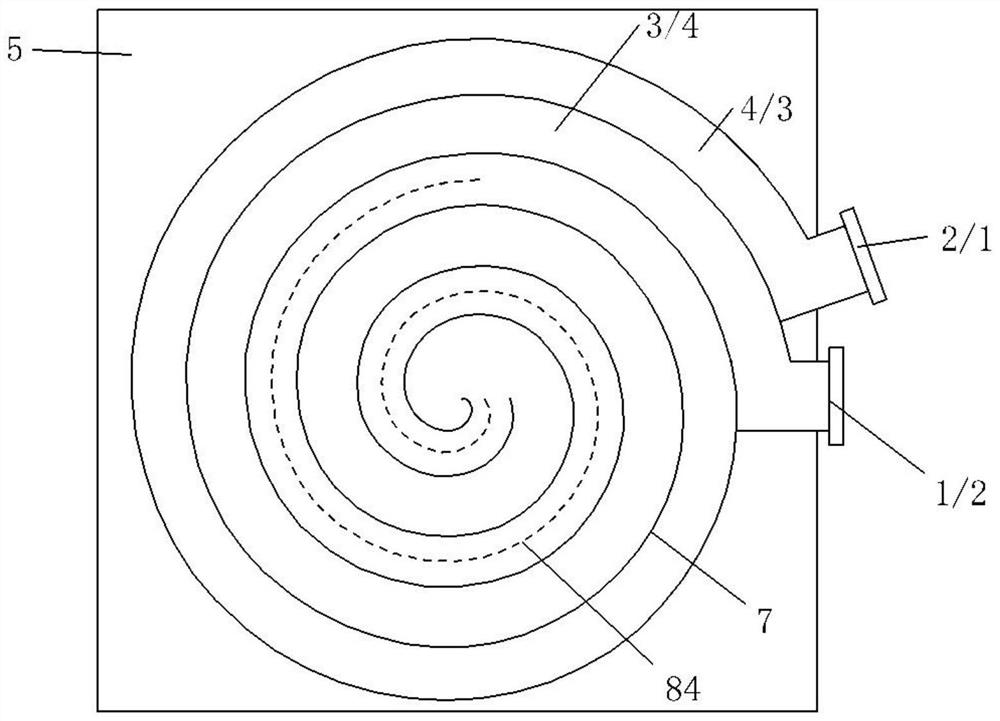

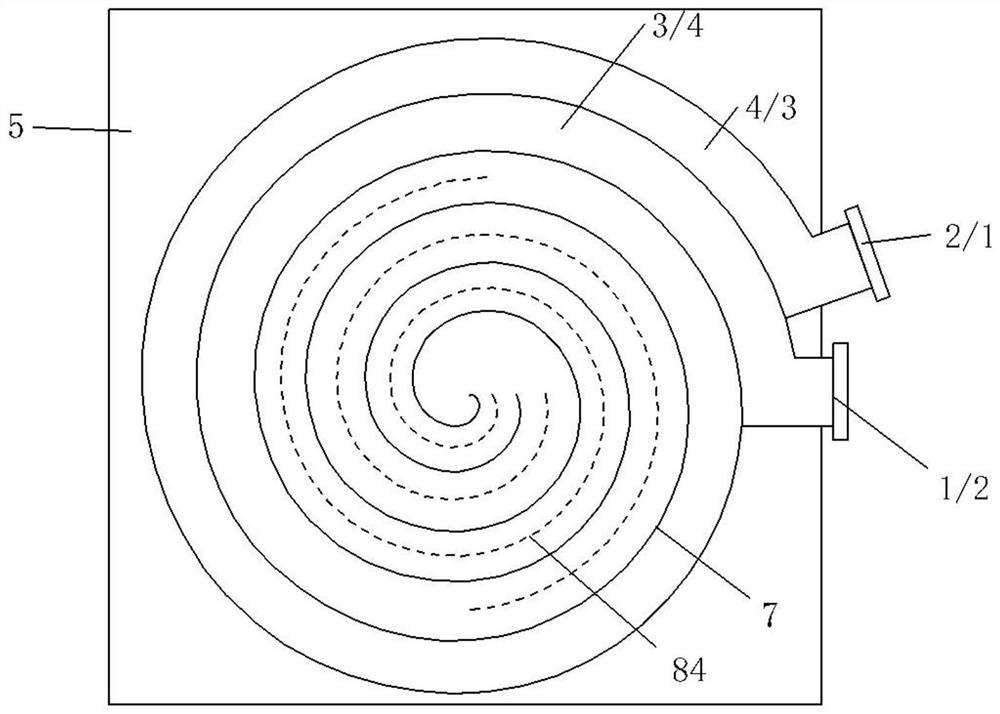

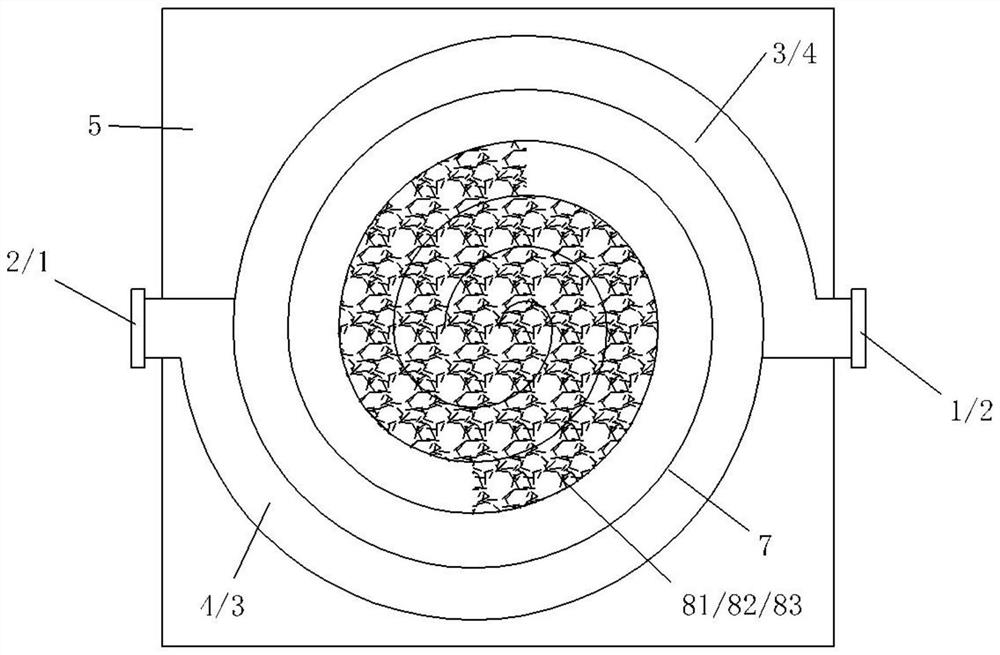

[0016] A coiled plate type autothermal catalytic oxidizer, comprising a reactor body, an air inlet 1 and an exhaust port 2, characterized in that: the reactor body is composed of at least two spiral coiled plates 7, and the spiral coiled plates on the reactor body The end of 7 is provided with a side cover 5, at least two spiral coiled plates 7 are nested and arranged to isolate at least two layers of adjacent spiral passages, at least one layer of spiral passages communicates with the air inlet 1 to form an air intake passage 3, at least One layer of spiral passage communicates with the exhaust port 2 to become th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap