Dry paint spraying chamber capable of separating paint from mist

A paint mist separation and spray booth technology, applied in the field of spray booths, can solve the problems of spray booth cost, high maintenance cost, difficult wastewater treatment, and difficult to cover costs, etc., and achieve simple structure, cost saving, and small paint loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

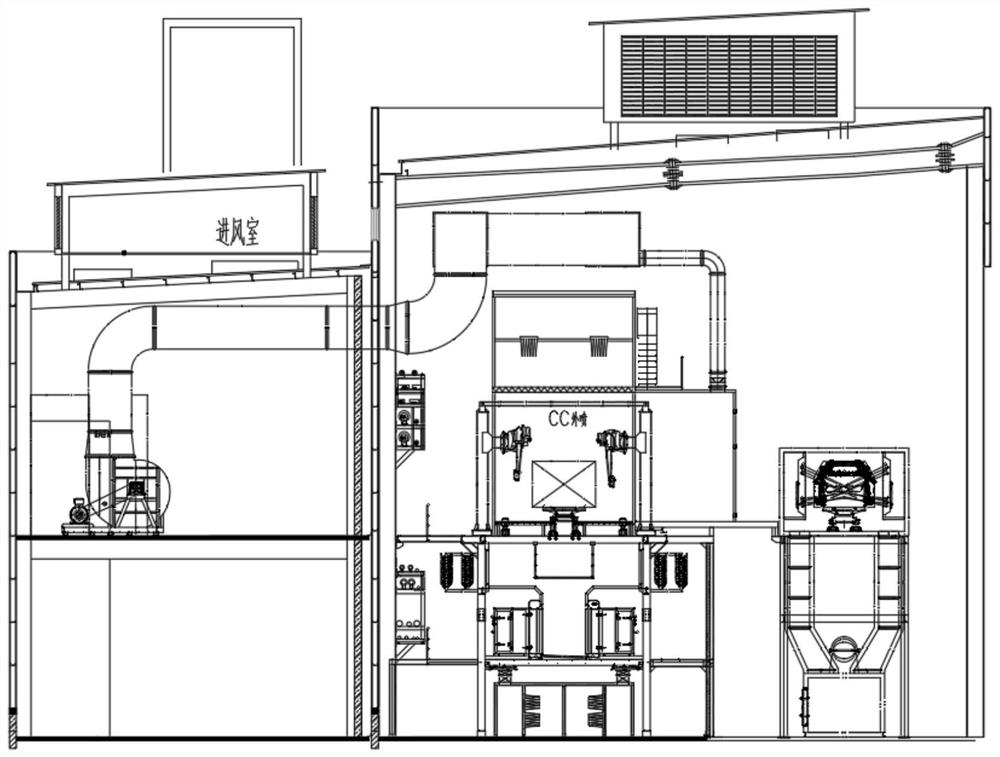

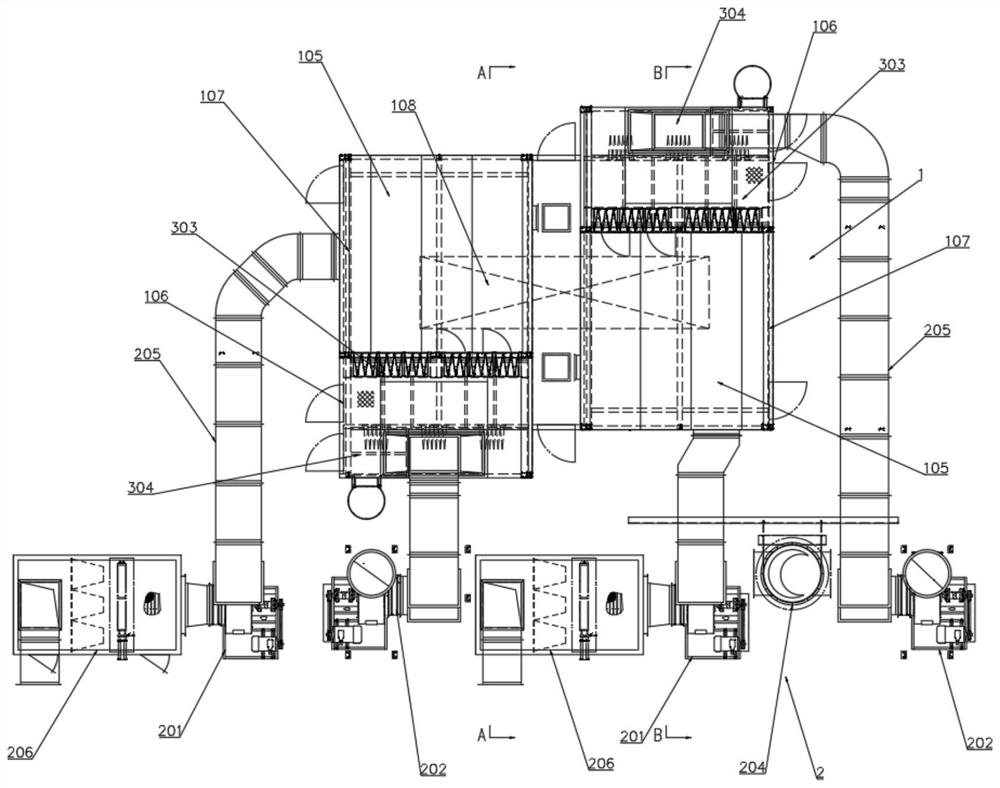

[0050] Such as figure 2 Shown, a dry paint mist separation spray booth 105 is characterized in that: comprising

[0051] frame body 1,

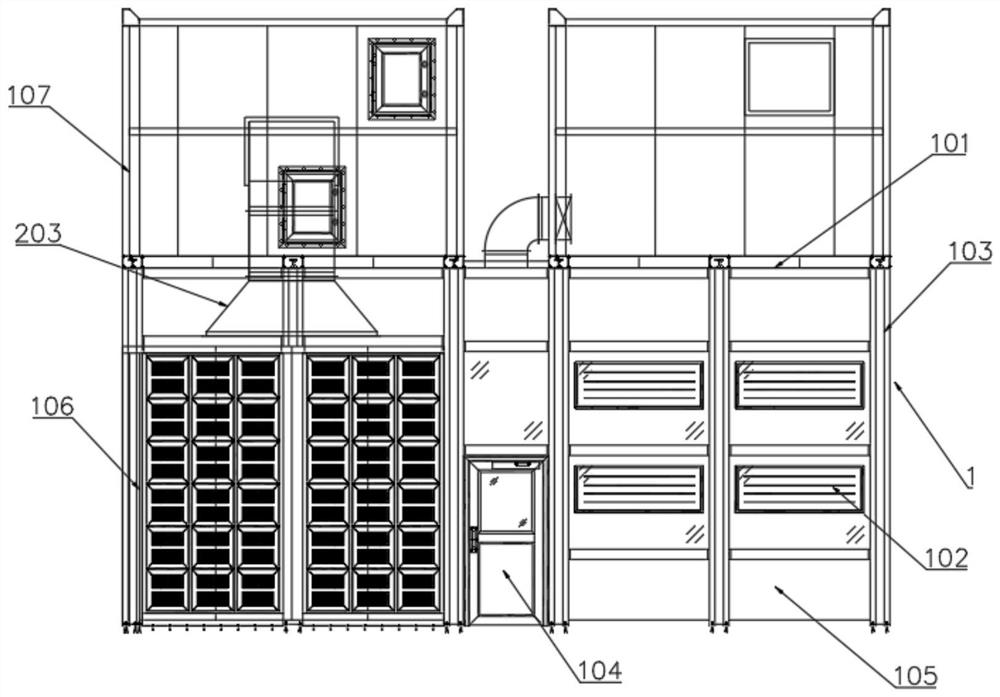

[0052]The frame mechanism 1 includes a pressure equalization chamber 107, a paint spraying chamber 105, and a dry filter chamber 106, each of which has two paint spraying chambers 105 and two dry filter chambers 106, and is located in the chamber body 103, and the outer wall of the paint spraying chamber 105 is provided with a personnel entrance and exit 104 ; The center of the chamber body 103 is also provided with a traveling passage 108, and two groups of spray booths 105 and dry filter chambers 106 are respectively symmetrically arranged on the left and right sides of the traveling passage 108, and the paint spray booth 105 and the dry filter chamber 106 are respectively located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com