Knife grinder capable of being adjusted at multiple angles

A knife sharpening machine, multi-angle technology, applied in the direction of grinding frame, grinding slide, grinding bed, etc., can solve the problems of increasing production cost, occupying workshop space, increasing tool cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

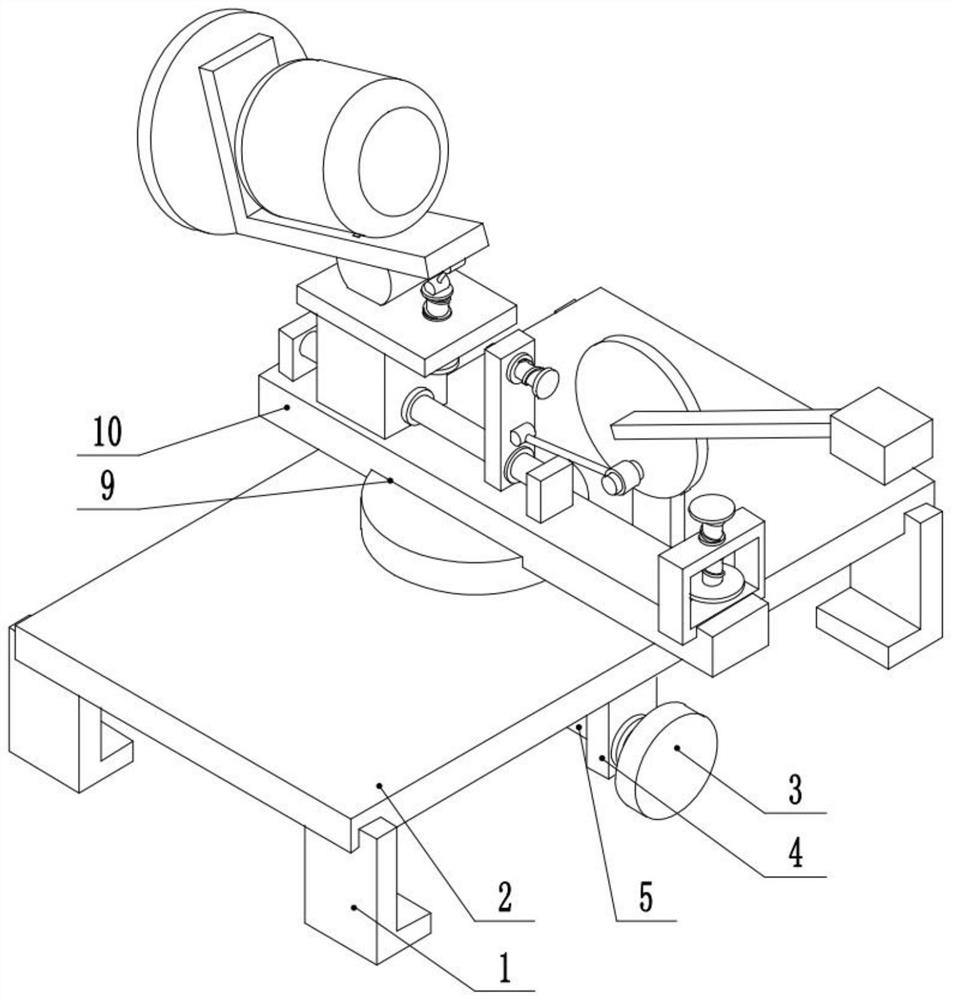

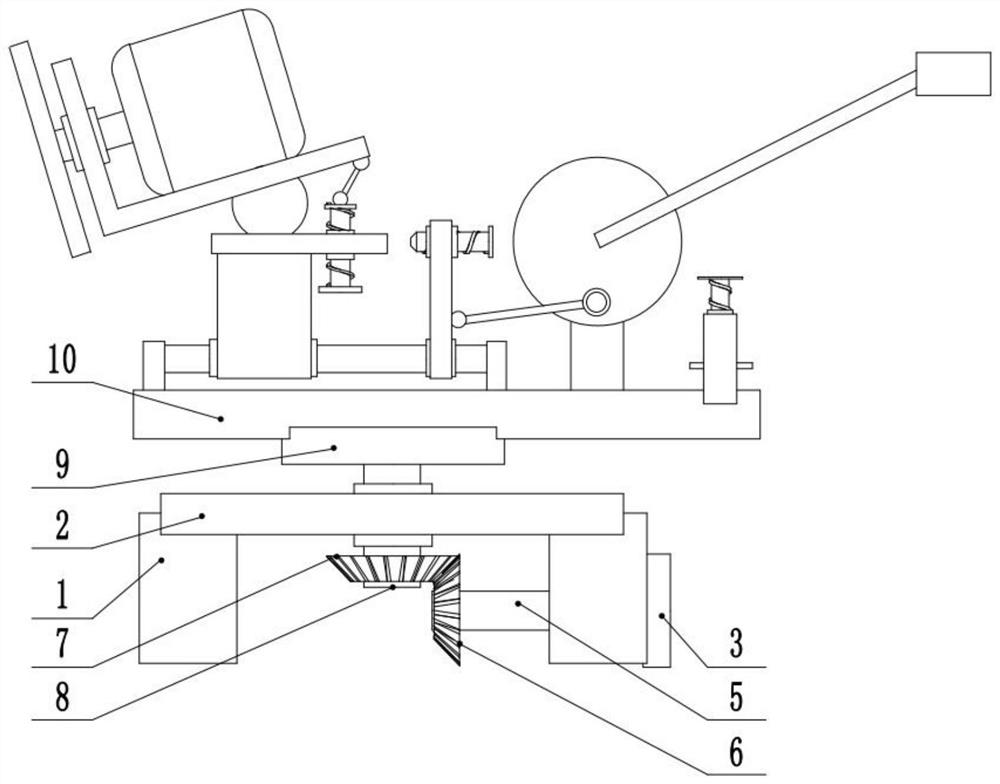

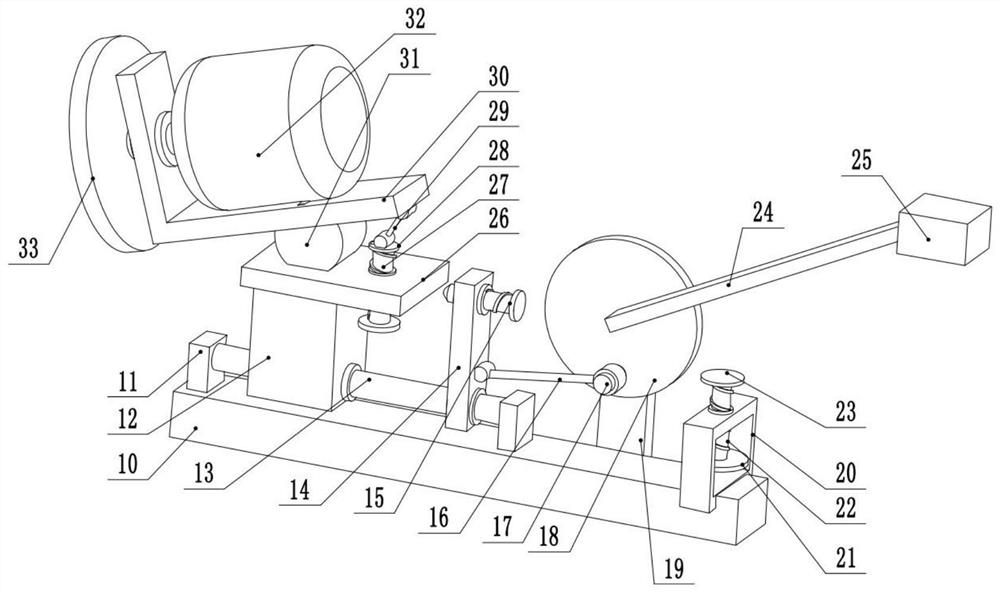

[0026] see Figure 1-4 , a multi-angle adjustable knife grinder, comprising a fixed table 2, the middle part of the fixed table 2 is rotatably connected to the middle part of the second rotating shaft 8, the upper end of the second rotating shaft 8 is provided with a first rotating disk 9, and the first rotating disk 9 The middle part is fixedly connected to the middle part of the rotating plate 10. The middle part of the lower surface of the fixed table 2 is provided with a first rotating shaft 5, and the left end of the first rotating shaft 5 is provided with a first bevel gear 6, the first bevel gear 6 meshes with the second bevel gear 7, and the second bevel gear 7 is fixedly connected The lower end of the second rotating shaft 8. The right side of the lower surface of the fixed table 2 is provided with a first fixed plate 4 , the middle part of the first fixed plate 4 is rotatably connected to the middle part of the first rotating shaft 5 , and the right end of the first...

Embodiment 2

[0030] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the lower surface of the fixed platform 2 is provided with mounting seats 1 on the front and rear sides. This device can be used in conjunction with some tool fixing devices, or directly placed in some processing equipment. It is not necessary to remove the tool during the process of grinding the tool of the processing equipment, which is convenient for operation. It is convenient for the installation of the whole device.

[0031] In the implementation process of the present invention, the device is fixed in the tool clamping device. At this time, the first runner 3 is rotated, and the first runner 3 drives the first rotating shaft 5 to rotate. The first rotating shaft 5 passes through the first bevel gear 6 and The second bevel gear 7 drives the second rotating shaft 8 to rotate, the second rotating shaft 8 drives the first rotating disk 9 to rotate, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap