Telescopic mechanism for power transmission line iron tower body climbing robot

A technology of transmission line iron towers and telescopic mechanisms, applied in the field of telescopic mechanisms, can solve problems such as imperfections, inconvenient robot operations, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

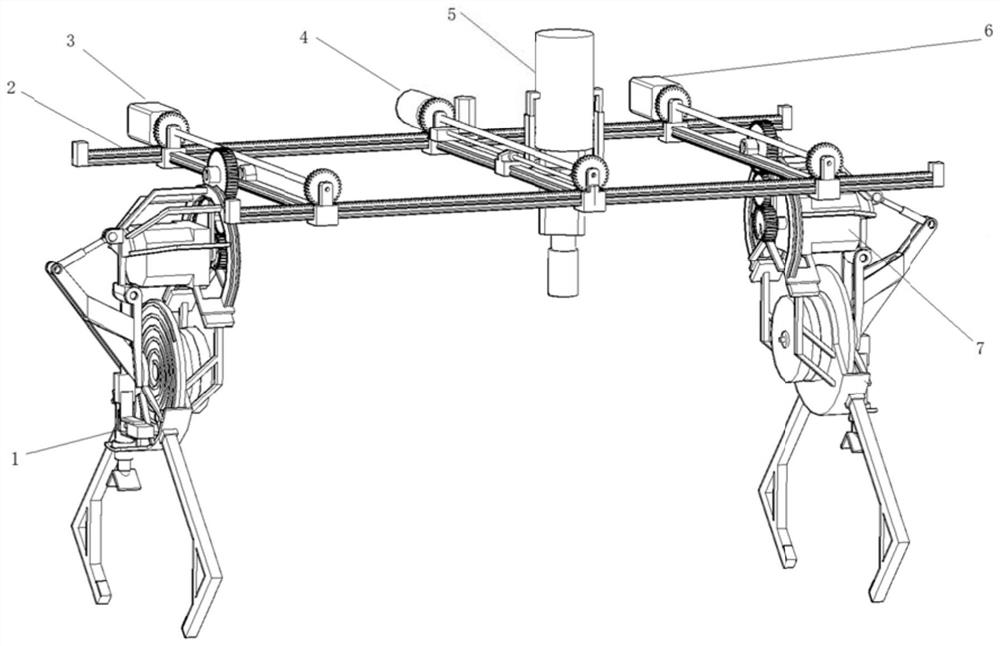

[0077] Embodiment 1, combining figure 1 The present invention provides a kind of telescopic mechanism that is used for the tower body climbing robot of power transmission line, comprises robot frame, the intermediate mechanism 7 that is arranged on the same side as robot frame and clamping mechanism 1; frame connection;

[0078] The intermediate mechanism 7 includes a push rod assembly;

[0079] Robot framework comprises track 5 and the cross bar that is vertically arranged with track 5;

[0080] The push rod assembly pushes the cross bar to slide along the track 2.

[0081] The crossbar includes a main crossbar with linkage gears installed at both ends, an auxiliary crossbar arranged parallel to the main crossbar, and a stepper motor installed at one end of the crossbar;

[0082] The axis between the main crossbar and the auxiliary crossbar is perpendicular to the axis of the track on the same vertical plane, and the end point on one side of the main crossbar is connected ...

Embodiment 2

[0098] In order to realize a robot technology and product capable of autonomous climbing, tower body attachment and working position locking, bolt identification, positioning and fully automatic fastening operations, the present invention mainly solves the following technical problems:

[0099] (1 the structural form of existing climbing robot can't adapt to the rigid structure climbing of this kind of angle steel tower with complex surface obstacle.

[0100] (2 the existing iron tower climbing robot can't realize the effective attachment and locking at any part of the angle steel tower body, and carry out the operation of the tower body with tools.

[0101] (3 The foot structure of the existing iron tower climbing robot is complex and difficult to control, and it is impossible to realize effective clamping at the position where there are obstacles on the surface of the angle steel tower, such as the connecting plate and the foot nail, and the mechanical self-locking property is ...

Embodiment 3

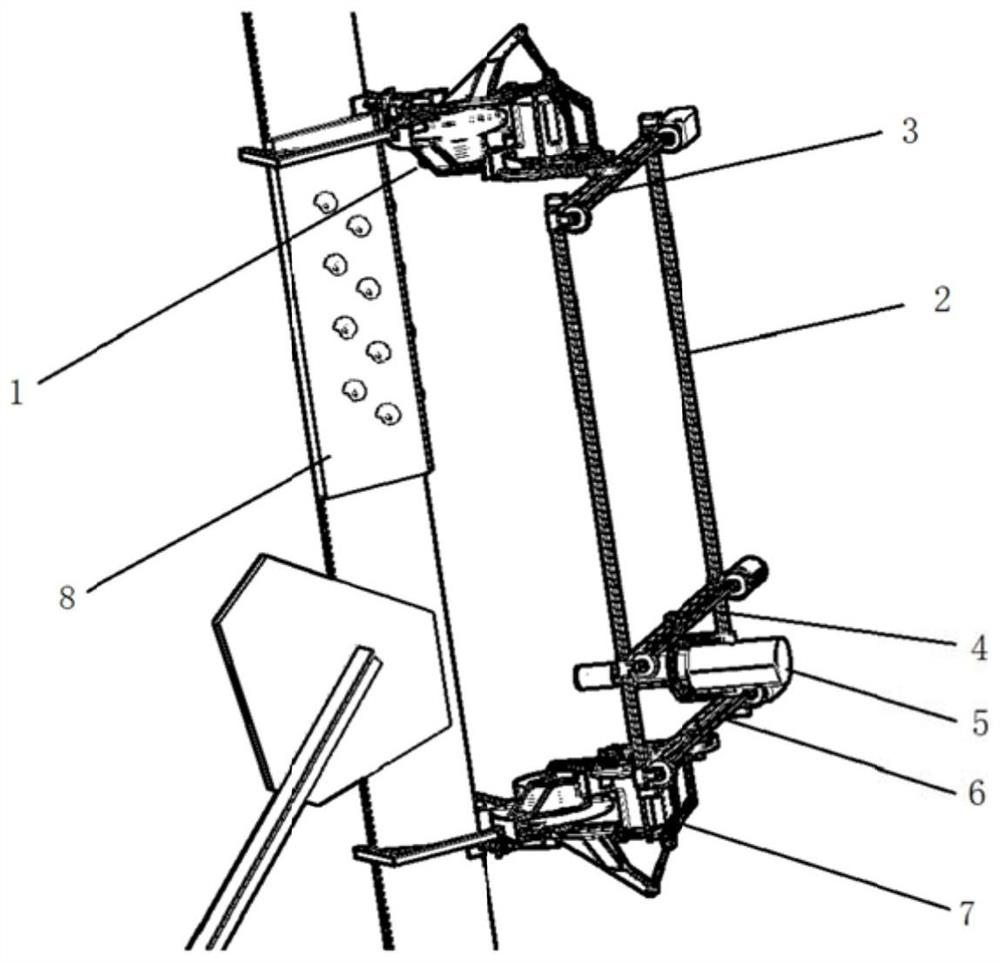

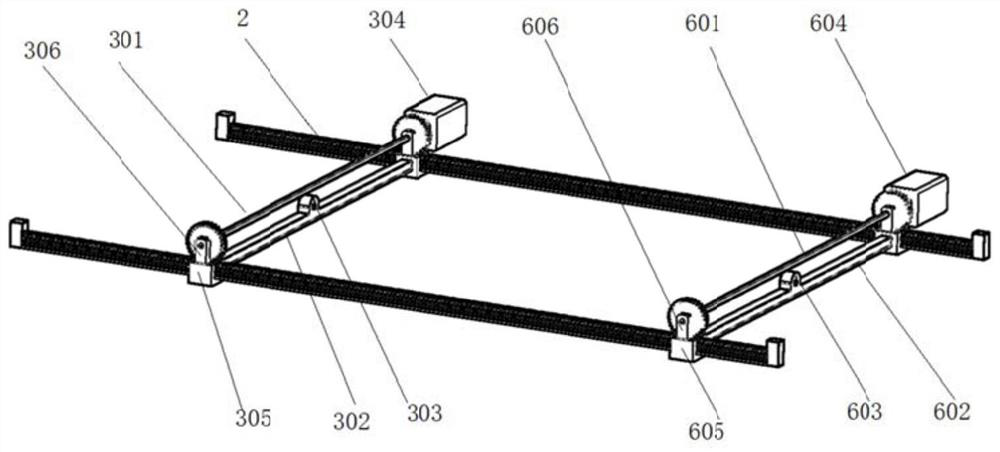

[0121] In the present invention, the front foot moving crossbar 3, the rear foot moving crossbar 6 and the middle moving crossbar 4 are arranged on the track 2, so that the three crossbars can move on the track 2;

[0122] The track 2 includes: a track plug 201, a rack 202, a slide rail 203, the rack 202 and the slide rail 203 are axially connected in parallel and the axis is in a vertical plane, and the track plug 201 is arranged at both ends of the slide rail 203;

[0123] The forefoot moving crossbar 3 includes: the forefoot moving crossbar linkage gear 301, the forefoot auxiliary moving crossbar 302, the forefoot keyway connection part 303, the front foot main moving crossbar stepper motor 304, the forefoot moving crossbar chute 305, the forefoot moving crossbar The lug 306, the main cross bar and the auxiliary cross bar are arranged in parallel, and the two ends are sequentially connected to the front foot mobile cross bar linkage gear 301, the front foot mobile cross bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com