Linear transportation device for mechanical parts

A technology for transportation devices and mechanical parts, applied in the field of linear transportation devices for mechanical parts, can solve problems such as high production costs, large power consumption, and low efficiency, and achieve the effects of improving energy conversion rates, reducing transportation resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

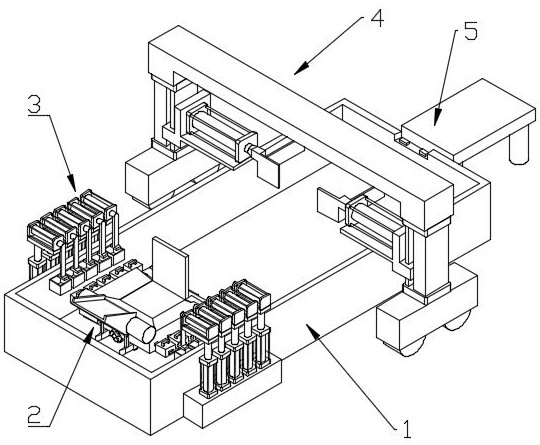

[0039] like Figure 1-Figure 7 , Figure 9 A linear transportation device for mechanical parts shown includes a tank body 1 and a transportation unit 2 .

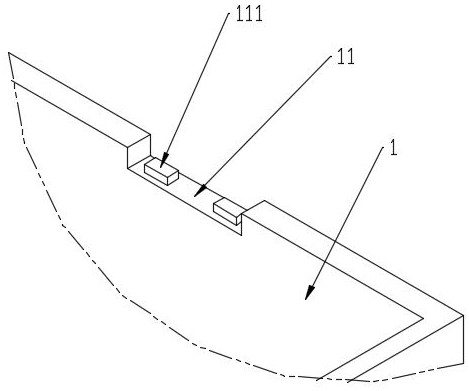

[0040] The pool body 1 is filled with water, and the upper end surface of the pool body 1 is provided with a mounting groove 11, and a plurality of fixing blocks 111 are arranged on the mounting groove 11, and a pair of brackets 12 are provided on both sides of the pool body 1;

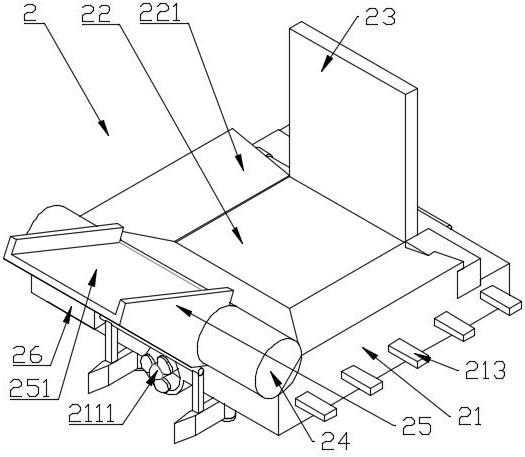

[0041]The transportation unit 2 is arranged on the water surface in the pool body 1. The transportation unit 2 includes a hull 21, one end of the bottom end of the hull 21 is provided with a forward motor 211, the other end is provided with a backward motor 212, and the output end of the forward motor 211 is provided with a forward propeller 2111. The output end of the retreating engine 212 is provided with a retreating propeller 2121, and the two sides of the hull 21 are arrayed with a plurality of floating block frames 213. The floating block fr...

Embodiment 2

[0049] Such as Figure 1-Figure 13 The shown linear transport device for mechanical parts includes the linear transport device for mechanical parts in Embodiment 1 and an adjustment unit 3 .

[0050] The adjustment unit 3 is arranged on both sides of the pool body 1, and is used to adjust the buoyancy of the hull 21. The adjustment unit 3 includes a plurality of third uniaxial cylinders 31 arrayed on the bracket 12, and the third uniaxial cylinder 31 vertically arranged One end of the output shaft is provided with a first horizontal frame 311, the first horizontal frame 311 is provided with a fourth uniaxial cylinder 32, one end of the output shaft of the fourth uniaxial cylinder 32 is provided with a vertical frame 33, and the bottom surface of the vertical frame 33 is provided with a hanging plate 331, one end of the hanging plate 331 is provided with a pulling plate 3311, and the other end is provided with a pushing plate 3312, and the number of a plurality of floating bloc...

Embodiment 3

[0059] Such as Figure 1-Figure 14 The shown linear transport device for mechanical parts includes the linear transport device for mechanical parts of Embodiment 1 and Embodiment 2, and a pick-up unit 4 .

[0060] The pick-up unit 4 includes a pair of car bodies 41, which are used to push the parts on the transport unit 2 to the parts table 5. The bottom surface of the car body 41 is provided with some rollers 411, and the upper end surface of the car body 41 is provided with a vertically arranged rodless A linear cylinder 42, one side of the rodless linear cylinder 42 is slidingly fitted with a second horizontal frame 421, one end of the second horizontal frame 421 is provided with a fifth uniaxial cylinder 43, and one end of the output shaft of the fifth uniaxial cylinder 43 is provided with a conversion block 44, The lower end of the conversion block 44 is provided with a width-limiting plate 441 , one end of the width-limiting plate 441 is provided with a push plate 442 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com